Superior Performance in Eccentric Segment Ball Valves

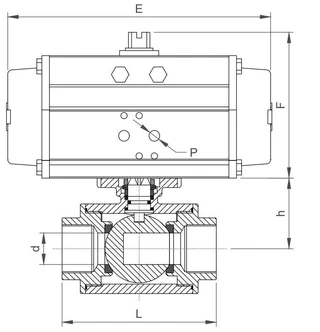

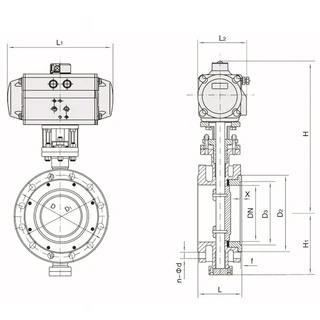

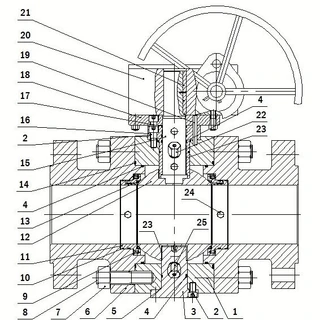

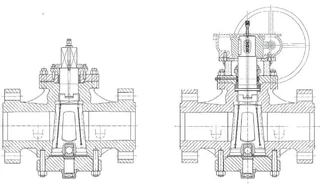

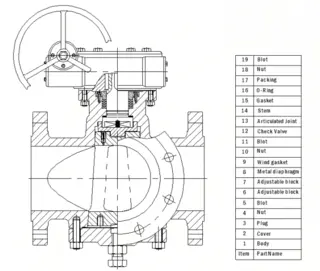

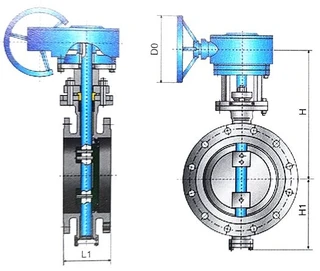

The eccentric segment ball valve, also known as the eccentric half-ball valve, is a widely used design in industrial ball valves, distinguished by the eccentric structure within the ball shape. This design not only allows fluids to pass with minimal resistance during valve opening and closing but also enhances the reliability of ball valves in high-temperature, high-pressure, and corrosive environments. Types of Eccentric Segment Ball Valves Eccentric segment ball valves are primarily...