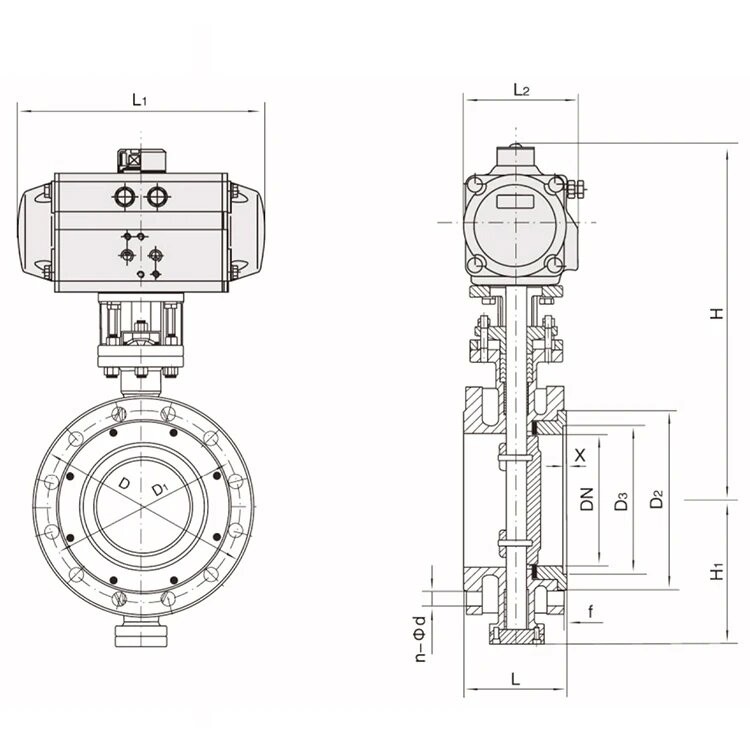

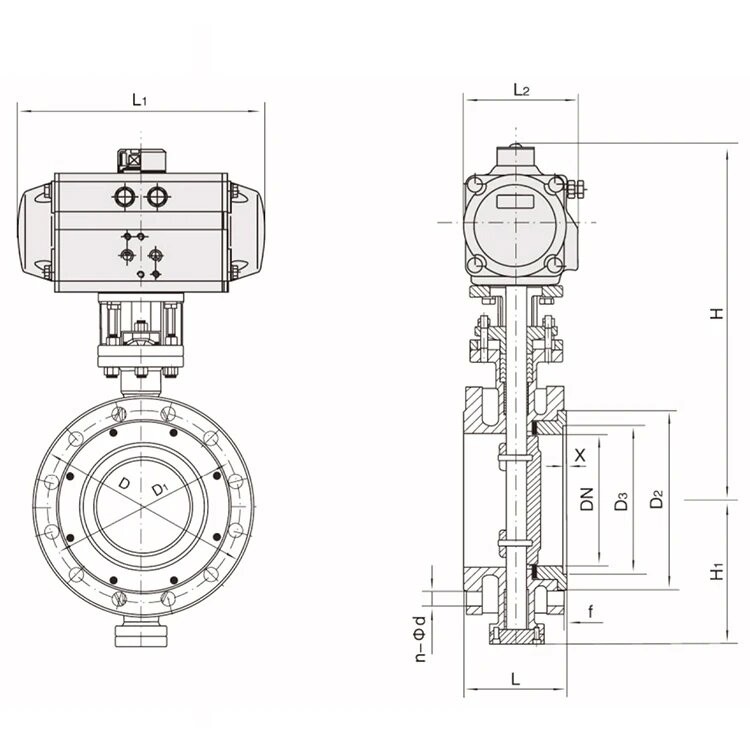

Pneumatic Hard Seal Butterfly Valve: A High-Quality Pipeline Control Device

The pneumatic hard seal butterfly valve stands out as a high-quality, long-lasting solution for pipeline control. Designed based on the three-dimensional eccentric principle, these butterfly valves are primarily composed of flanged or clamp-type hard-sealed butterfly valves connected to a pneumatic actuator. The sealing faces of the valve seat and disc are made of metal materials or stainless steel with different hardness, endowing the butterfly valve with advantages such as high-temperature resistance, corrosion resistance, and wear resistance.

1. Structural Features of Pneumatic Hard Seal Butterfly Valve

These valves use a pneumatic actuator to open or close the valve disc, and they are known for their durability and ability to withstand high-pressure and high-temperature conditions. Here are the key structural features of a pneumatic hard seal butterfly valve:

2. Its Performance Features

Pneumatic hard seal butterfly valves offer several performance features that make them suitable for various industrial applications. Here are some key performance features of these valves:

3. The Structural Characteristics Comparison

4. The Valve's Performance Advantages

In conclusion, the pneumatic hard seal butterfly valve, with its long lifespan, high quality, multilayered sealing structure, and flexible operation, is an indispensable device in the field of pipeline control. Its performance advantages allow it to perform fluid control tasks reliably and stably in various operating

1. Structural Features of Pneumatic Hard Seal Butterfly Valve

These valves use a pneumatic actuator to open or close the valve disc, and they are known for their durability and ability to withstand high-pressure and high-temperature conditions. Here are the key structural features of a pneumatic hard seal butterfly valve:

Three Eccentric Principle Structure: The use of the three eccentric principle in design ensures minimal friction between the valve seat and disc during opening and closing, significantly improving the valve's lifespan.

Multilayered Structure for Compatibility: The valve employs a multilayered structure compatible with both hard and soft seals, ensuring excellent sealing performance in both low and high-temperature conditions. During valve operation, the disc and seat experience minimal friction, greatly enhancing the valve's lifespan.

Wide Application: Widely applied in pipelines conveying electricity, oil, steam, air, sewage, and other media, the pneumatic hard seal butterfly valve is considered the optimal device for switching control or regulating flow.

Multilayered Structure for Compatibility: The valve employs a multilayered structure compatible with both hard and soft seals, ensuring excellent sealing performance in both low and high-temperature conditions. During valve operation, the disc and seat experience minimal friction, greatly enhancing the valve's lifespan.

Wide Application: Widely applied in pipelines conveying electricity, oil, steam, air, sewage, and other media, the pneumatic hard seal butterfly valve is considered the optimal device for switching control or regulating flow.

2. Its Performance Features

Pneumatic hard seal butterfly valves offer several performance features that make them suitable for various industrial applications. Here are some key performance features of these valves:

Flexible Operation: The unique structure allows for flexible, effortless operation that is unaffected by variations in medium pressure, ensuring reliable sealing performance.

Various Connection Methods: Available in pneumatic clamp-type hard seal butterfly valves and pneumatic flange-type hard seal butterfly valves, catering to different connection requirements and facilitating installation in pipelines.

Superior Sealing Performance: The sealing mechanism, consisting of layered soft and hard metal sheets, possesses the dual advantages of metal sealing and elastic sealing. This guarantees excellent sealing characteristics in both low and high-temperature conditions.

Adjustment Mechanism: Equipped with a sealing adjustment device, the valve allows for the adjustment of the disc sealing ring over extended periods of use. This feature restores the original sealing performance, significantly extending the valve's operational life.

Various Connection Methods: Available in pneumatic clamp-type hard seal butterfly valves and pneumatic flange-type hard seal butterfly valves, catering to different connection requirements and facilitating installation in pipelines.

Superior Sealing Performance: The sealing mechanism, consisting of layered soft and hard metal sheets, possesses the dual advantages of metal sealing and elastic sealing. This guarantees excellent sealing characteristics in both low and high-temperature conditions.

Adjustment Mechanism: Equipped with a sealing adjustment device, the valve allows for the adjustment of the disc sealing ring over extended periods of use. This feature restores the original sealing performance, significantly extending the valve's operational life.

3. The Structural Characteristics Comparison

- Environment Suitability for Soft and Hard Seals: Soft seals are suitable for low pressure to atmospheric conditions, while hard seals can handle medium to high-pressure conditions. Soft seals are suitable for low and ambient temperature environments, whereas hard seals can be employed in low, ambient, and high-temperature settings.

- Valve Structure Types: Soft seal butterfly valves often have a centerline structure, while hard seals typically feature single eccentric, double eccentric, and three eccentric butterfly valve structures.

- Performance Comparison: In high-pressure, high-temperature environments, three eccentric hard seal butterfly valves maintain superior sealing compared to soft seal butterfly valves.

4. The Valve's Performance Advantages

- Simple, Lightweight Structure: The valve's simple structure, small size, and lightweight contribute to lower costs. Controlled by a two-position five-way solenoid valve, the operation is convenient and allows for flow medium adjustment.

- Low Closing Torque: With minimal fluid resistance, the pneumatic hard seal butterfly valve exhibits a large effective flow area when fully open, enabling quick and effortless opening and closing. The disc rotation of 90 degrees completes the operation, and due to the equal forces acting on both sides of the disc by the medium, the resulting torque is small, ensuring excellent sealing under low pressure.

- Versatile Materials: Its sealing materials, including but not limited to rubber, fluororubber, and edible rubber, provide outstanding sealing performance, especially in low-temperature conditions.

In conclusion, the pneumatic hard seal butterfly valve, with its long lifespan, high quality, multilayered sealing structure, and flexible operation, is an indispensable device in the field of pipeline control. Its performance advantages allow it to perform fluid control tasks reliably and stably in various operating