Company Profile

Established in 2000, JSC Valve has emerged as a leading valve manufacturer and service provider in China. Our strategic location in the esteemed "Chinese Pump & Valve Town" of Oubei, within Wenzhou city, Zhejiang province, covers a vast area of 21,000 square meters. With a seamless integration of design, production, examination, sales, and service, we are dedicated to providing comprehensive solutions within the valve industry.

Product Portfolio and Specifications

Our product portfolio boasts a diverse range, including ball valves, butterfly valves, gate valves, globe valves, check valves, plug valves, various valve components, parts, pipes, and fittings. Operating under diverse working pressures (Class 150 LB to 2500 LB, PN6 to PN420) and sizes (NPS 1/4 Inch to 80 Inch, DN6 to DN2000), our materials comprise castings like ASTM A216 WCB, ASTM A352 LCB, LC1, ASTM A351 CF8, CF8M, CF3M, CF3, ASTM A217 C5, WC6, WC9, monel, duplex, and forged materials such as ASTM A105, ASTM A182 F11, F22, F91, F304, F316, F51, F321, F347, Inconel, etc. Our valves cater to working temperatures from -196℃ to 680℃, adhering strictly to ANSI, API, DIN, BS, JIS, EN, GOST standards. They find application across diverse industries, including Petrochemical, Oil, Gas, Power Plant, Refining, and Metallurgy.

Quality Assurance and Accreditations

Stringent quality control measures are in place to not only meet but exceed customer expectations. JSC Valve holds accreditations from ISO 9001:2000, PED, API 607, API 6D, and API 600, emphasizing our commitment to delivering high-quality solutions.

Global Reach and Product Recognition

With a global presence extending to America, Europe, Southeast Asia, the Middle East, and Africa, our valves have earned widespread approval. Particularly, the TRIC butterfly valve and SDV ball valve, under the JSC Valve brand, stand as testament to our commitment to excellence and customer satisfaction.

Advanced Manufacturing

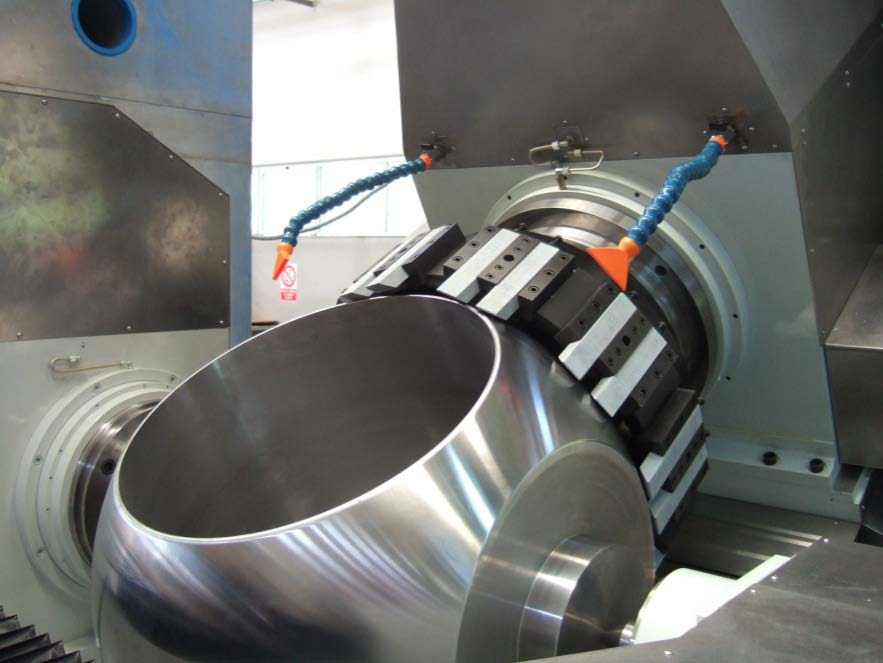

Modern numeric control machining equipment to achieve the high quality of valve internal.

Massive pressure testing facilities are used to guarantee the sealing performance of each valve.

Ultrasonic cleaning equipment and automatic valves painting system to improve the visual looking of the valves. Our factories are producing "beautiful".

Innovative Technology

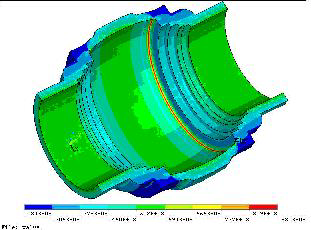

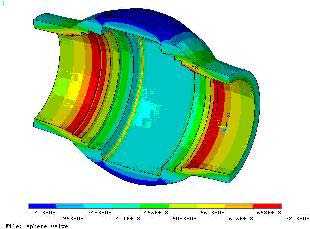

With high educated and well trained engineers, using the latest CAD & CAM system, three dimensional system and limited elementary analysis in the factories, JSC VALVE Company keeps developing innovative designs and products, such as fully welded underground ball valves, forged one piece body top entry ball valves, high temperature metal to metal seat ball valves, etc.

Next: Quality Control

Previous: Company Culture