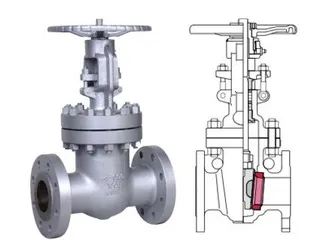

API 6A Expanding gate valve 7 1/16'' 5000PSI, DD,PR1,PSL 1

API 6A Expanding gate valve 7 1/16'' 5000PSI, DD,PR1,PSL 1 API 6A Expanding gate valve Valves consists of one gate body and related gate segment. The contact surface between are designed to milled V structure. Expanding Gate valves are available in sizes 2-1/16 "through 4-1/16". working pressure of 2000 psi through 5000 psi. API 6A Expanding Gate Valves are commonly used in oil and gas production, refining, and petrochemical industries. These valves are designed...