Failure Analysis of Rubber Seals in Industrial Valves

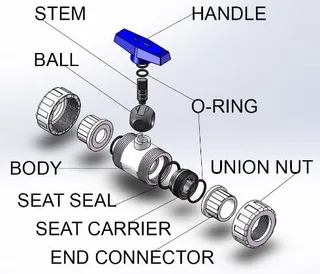

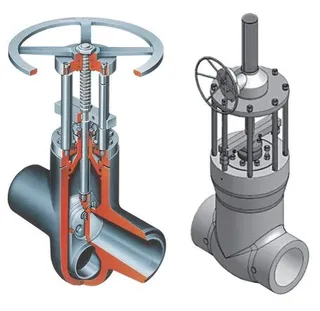

In industrial valves, rubber seals play a crucial role. They not only prevent fluid leakage but also ensure the proper operation and stability of the system. The quality of the seals directly affects the performance and lifespan of the valve. Therefore, seal failure can lead to decreased efficiency, operational failures, or even safety incidents. Understanding the role of rubber seals, the causes of their failure, and taking preventive measures are essential to maintaining the stable operation of...