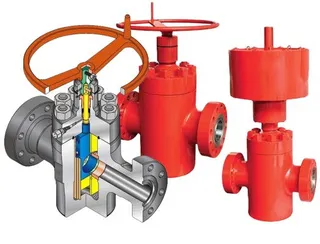

How to Improve Casting & Sealing of Oil Wellhead Gate Valves

The gate valve used in oil wellhead equipment, commonly known as the "Christmas tree", is essential in oil field operations. These valves are widely used in the oil extraction process to control the flow of oil by opening and closing as needed. However, the current wellhead gate valves have a relatively low qualification rate in production, especially during hydrostatic strength and sealing performance tests, with rates ranging from just 30% to 70%. These issues not only impact the lifespan...