Differences between Lubricated and Non-Lubricated Plug Valves

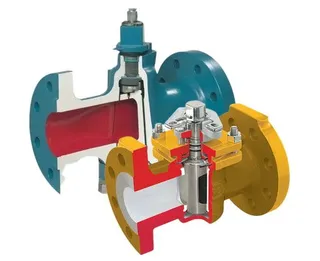

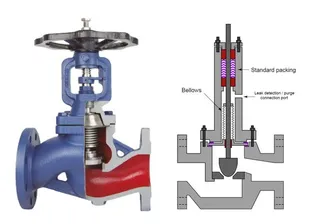

Plug valves are essential components in fluid control systems due to their simple structure, ease of operation, and excellent sealing performance. They are widely used in industries such as oil and gas, chemical, mining, and others. Depending on the lubrication method, plug valves can be classified into lubricated and non-lubricated types. This article will explore the structure, working principles, advantages and disadvantages, and specific applications of these two types of plug valves,...