Characteristics and Advantages of Resilient Seated Gate Valves

On this page

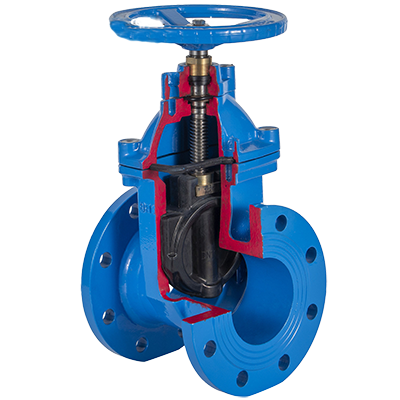

Resilient seated gate valves are an innovative valve design, primarily composed of a ductile iron body and a full-coverage, non-toxic rubber gate. These valves are particularly suitable for industrial applications that require high sealing performance and corrosion resistance. This article will explore the structural features, working principles, main advantages, and applications of resilient seated gate valves across various industries to demonstrate their importance in modern fluid control systems.

The design of resilient seated gate valves exhibits several notable structural features that enhance their functionality and ensure efficient performance in complex environments. Here are the main structural features of the valve.

Gate: Made from high-quality, full-coverage, non-toxic rubber (such as directly vulcanized nitrile rubber or ethylene-propylene-diene rubber), it offers excellent elasticity and wear resistance. It can undergo slight elastic deformation under force, achieving a good sealing effect.

Body: Manufactured using ductile iron, it has high strength and toughness. Special treatments further enhance its corrosion and wear resistance, making it suitable for harsh environments.

The interior and exterior surfaces of the valve are coated with epoxy resin powder paint, forming a smooth and robust protective layer. This coating not only prevents corrosion but also ensures cleanliness and aesthetics during long-term use.

Self-sealing Principle: Resilient seated gate valves use the pressure of the medium to achieve automatic sealing. The gate, under the influence of medium pressure, tightly adheres to the seat, ensuring zero leakage. This design not only improves the reliability of sealing but also reduces the need for external force application by operators.

O-ring Seal: The stem sealing uses an O-ring design, avoiding leakage issues that can occur with traditional valve packing. It also reduces friction resistance and extends the service life.

Non-recessed Bottom: The valve bottom is designed as a flat surface, level with the pipeline, reducing the possibility of debris accumulation and ensuring smooth fluid flow.

Straight-through Body: The valve features a straight-through design, optimizing the fluid flow path, reducing flow resistance and head loss, and improving flow efficiency.

The working principle of resilient seated gate valves mainly relies on the pressure of the medium. In the open state, the gate is pressed against the seat by the medium pressure, forming a good seal. Unlike traditional metal gate valves, resilient seated gate valves can achieve sealing without external force application, reducing operational difficulty and maintenance costs. This self-sealing mechanism makes the valve more reliable in sealing performance and suitable for controlling various fluid media.

Resilient seated gate valves stand out among many valves with their unique design and excellent performance, offering several significant advantages suitable for various fluid control scenarios. Here are the main advantages of resilient seated gate valves.

Superior Sealing Performance: With rubber gates sealing against cast components, resilient seated gate valves can achieve zero leakage, ensuring the safe transmission of fluids and preventing environmental pollution.

Low Friction and Wear Resistance: The valve has a low coefficient of friction, requiring low torque for operation, making it flexible and reducing wear, thus extending its service life. This feature makes the valve perform well in environments with frequent operations.

Excellent Corrosion Resistance: The high-quality materials and coatings used in the valve effectively prevent corrosion, allowing safe use in chemical and petroleum industries with corrosive media, reducing the frequency of maintenance and replacement.

Long Service Life: High-quality rubber and excellent manufacturing processes give the valve a longer service life, reducing maintenance and replacement costs for users.

Aesthetic Design: The aesthetic design of resilient seated gate valves is elegant and attractive, with epoxy resin coatings that enhance visual appeal, making them suitable for various installation environments, especially those with high aesthetic requirements.

Compact Structural Design: The overall valve cover features a concealed stem design, with a compact structure where the stem nut and gate are integrated, preventing jamming and enhancing stability.

Resilient seated gate valves are widely used in the following fields due to their unique advantages.

Water Treatment Systems: In potable water and wastewater treatment systems, resilient seated gate valves ensure reliable control of water flow, suitable for regulating and treating various water qualities.

Industrial Pipelines: In chemical, petroleum, and natural gas industries, resilient seated gate valves provide efficient fluid control, meeting the needs of complex working conditions.

Firefighting Systems: In firefighting pipelines, these valves ensure smooth water flow, ensuring the efficient operation of firefighting systems.

HVAC Systems: In HVAC systems, resilient seated gate valves are used for flow regulation, ensuring indoor environmental comfort.

Resilient seated gate valves, with their unique design, excellent sealing performance, and long-term durability, exhibit significant advantages in the valve market. As modern industry's requirements for fluid control continue to rise, resilient seated gate valves have become indispensable fluid control components in many industries due to their reliability, corrosion resistance, and ease of operation. In the future, with continuous technological advancements, these valves will play a vital role in more applications, ensuring the safety and efficiency of fluid control systems.