Quality Control

JSC Valve is committed to employing innovative and updated quality testing procedures, with a steadfast commitment to delivering superior industrial valves that are both high in quality and affordable. Our Quality Control (QC) division meticulously oversees every stage of production, rigorously implementing a series of quality control measures.

Quality Control Procedures for Raw Material

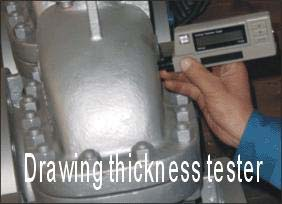

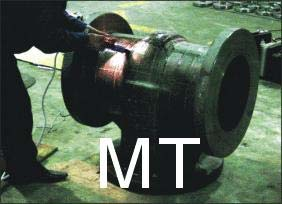

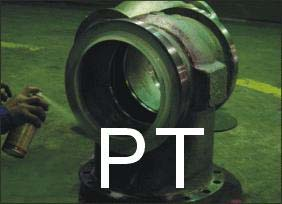

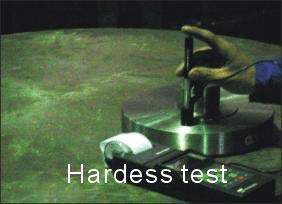

All our products undergo a 100% inspection by our quality department. Moreover, we welcome Third Party Inspections appointed by our customers. We provide comprehensive support for third-party inspections, including the review of foundries' mill test certificates 3.1B, testing equipment usage, and various testing procedures such as machining, chemical analysis, mechanical tests, ultrasonic thickness testing, MT, PT, and RT. At JSC Valve, we firmly believe that quality first is the key to winning our customers' satisfaction.

On every procedure from raw material input to the final valve out, we have intensive quality inspection and quality control. Non-Destructive tests such as Ultrasonic test, Magnetic Particle test, Dye-penetrate test, Radiographic test are widely used. All valves and materials have good traceability.

With the rapid expansion of production capacity and the continuous optimization of workflow as well as quality management system, JSC VALVE Company is ushering in a new round of development opportunities.

Quality Control Procedures for Raw Material

For our raw materials, we initiate a comprehensive quality control procedure. This involves inspection, final testing, and dispatch, all in accordance with the latest relevant standards and our clients' specific requirements. When receiving castings from foundries, our QC staff diligently inspects for the following:

1. Sand holes

2. Rib position

3. Heat number

4. Chemical composition and mechanical performance

5. Heat treatment

6. Riser cutting

2. Rib position

3. Heat number

4. Chemical composition and mechanical performance

5. Heat treatment

6. Riser cutting

Quality Control Plan for Machining Components

In the realm of machining components, our technical department computerizes all drawings and dimensions of internal construction. When an order is received, the drawings will be immediately printed out and handed over to the workshop for the machining of the various components. This computerized approach minimizes the likelihood of faulty machining, ensuring timely deliveries. Daily updates to the production slip on the computer provide real-time traceability and evaluation of the order's stage.

Quality Control Plan for Final Inspection

Our final inspection process is meticulous, with a particular focus on the pressure sealing test. Each valve undergoes a 100% hydraulic and pneumatic test. Before painting, our QC staff conducts a thorough check of the final dimensions and appearance. Once approved and stamped, the valves proceed to final cleaning, greasing, painting, labeling of nameplates, and packing for dispatch.

All our products undergo a 100% inspection by our quality department. Moreover, we welcome Third Party Inspections appointed by our customers. We provide comprehensive support for third-party inspections, including the review of foundries' mill test certificates 3.1B, testing equipment usage, and various testing procedures such as machining, chemical analysis, mechanical tests, ultrasonic thickness testing, MT, PT, and RT. At JSC Valve, we firmly believe that quality first is the key to winning our customers' satisfaction.

On every procedure from raw material input to the final valve out, we have intensive quality inspection and quality control. Non-Destructive tests such as Ultrasonic test, Magnetic Particle test, Dye-penetrate test, Radiographic test are widely used. All valves and materials have good traceability.

With the rapid expansion of production capacity and the continuous optimization of workflow as well as quality management system, JSC VALVE Company is ushering in a new round of development opportunities.

Next: Organization Structure

Previous: Company Profile