Advantages and Applications of Duplex Stainless Steel Valves

On this page

Duplex stainless steel valves are celebrated for their outstanding performance in harsh environments, thanks to their material properties and meticulous design. They are widely used in demanding industries such as marine engineering, petrochemical processing, and mining equipment. The excellence of duplex stainless steel comes from its unique microstructure and balanced composition; the solid solution structure contains approximately 50% ferrite and 50% austenite phases, typically ensuring that each phase is at least 30%. This composition combines the benefits of both ferritic and austenitic stainless steels—offering high strength and stress corrosion resistance along with toughness and weldability, making it suitable for a range of demanding conditions. Below are the main features and applications of duplex stainless steel valves.

The dual-phase structure of duplex stainless steel merges the strengths of ferrite and austenite, giving it exceptional corrosion resistance, strength, and welding performance. Here are the key performance highlights.

Duplex stainless steel, especially molybdenum-containing types, offers superior chloride stress corrosion resistance in low-stress environments. The material also provides excellent resistance to pitting, corrosion fatigue, and abrasion, making it ideal for environments with chlorides or hydrogen sulfide.

Duplex stainless steel has outstanding mechanical properties, boasting high strength and fatigue resistance. This material requires no preheating before welding and does not need post-weld heat treatment, simplifying installation and boosting project efficiency. Additionally, duplex grades with low chromium content (e.g., 18%Cr) have a wide hot-working temperature range, excellent thermal conductivity, and a low coefficient of linear expansion, ensuring stability during heat treatment and manufacturing.

Unlike high-chromium ferritic stainless steels, duplex stainless steel is less susceptible to embrittlement at high temperatures, providing stable performance across a broad temperature range, making it ideal for fluctuating temperature conditions.

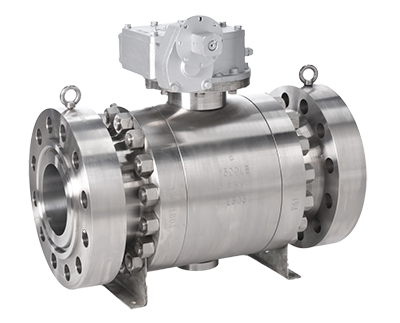

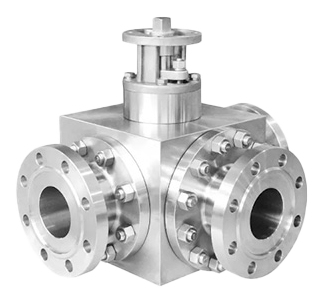

Duplex stainless steel valves typically feature integrally forged or forged-welded constructions. After non-destructive testing and solution treatment, the material achieves a dense structure with an appealing finish. To enhance wear resistance and durability, the sealing surfaces are often treated with hard alloy coatings, such as nickel-based, stellite, or tungsten carbide, reaching hardness levels of up to HRC65 for exceptional abrasion resistance. Due to the material properties of duplex steel, these valves perform excellently in resisting sulfide and chloride corrosion, ensuring durability in sulfur- and chloride-laden environments.

Duplex stainless steel ball valves are designed with a fixed ball structure for applications like coal-water slurry in high-temperature, scaling-prone media. This reduces the pressure exerted on the sealing surfaces, lowering operational torque. The valve stem is made from 17-4PH stainless steel treated through precipitation hardening to achieve high mechanical strength, effectively countering torque increases caused by scaling and meeting high-strength demands. Additionally, the closed valve seat structure prevents spring failure due to sediment accumulation, thus enhancing sealing performance and longevity.

Seals can be made from flexible graphite or plastic alloys. Flexible graphite withstands temperatures up to 800°C, while plastic alloys endure up to 300°C, ensuring excellent sealing performance in high-temperature environments and stable valve operation.

Due to its corrosion resistance, wear resistance, and high strength, duplex stainless steel valves suit various challenging conditions. Below are the properties of common materials and their respective application areas.

For environments requiring high corrosion resistance, such as marine engineering and chemical equipment, S31803 and S32205 are commonly selected. These materials offer excellent corrosion resistance while maintaining high mechanical strength and good weldability, especially effective in chloride or acidic environments.

In coal chemical and mining equipment, which often experience heavy wear, S32750 and S32760 materials are preferred. These materials have high hardness and outstanding wear resistance, ensuring stable long-term operation in abrasive conditions and extending equipment life.

In high-temperature equipment like boilers and heat exchangers, materials with strong heat resistance, such as S32550 and S32900, are ideal. These grades retain strength and toughness under high temperatures, ensuring adaptability and reliability under thermal stress.

For pressure vessels and high-load machinery in high-pressure environments, materials like S32520 and S32707, known for their high yield and tensile strengths, are used. These materials meet the high-strength requirements of high-pressure, high-load conditions, ensuring safe and stable equipment operation.

Duplex stainless steel valves, with their unique dual-phase structure, effectively combine the strengths of ferritic and austenitic stainless steels, exhibiting superior corrosion resistance, wear resistance, high-temperature durability, and high strength. They are essential in industries such as petrochemical, mining, boilers, and high-pressure systems. Whether facing chloride corrosion in marine environments or resisting wear in mining equipment, duplex stainless steel valves deliver long-term stability and safety in complex conditions, providing robust support for modern industrial applications.