The Advanced Design and Versatility of Trunnion Mounted Ball Valves

On this page

Trunnion mounted ball valves represent a high-performance valve technology, catering to the demands of long-distance and general industrial pipelines. Engineered with strength and resilience in mind, these valves are adept at handling both corrosive and non-corrosive media. The unique design of trunnion mounted ball valves sets the valves apart from their floating counterparts, ensuring efficient fluid pressure management, minimal torque requirements, and extended service life.

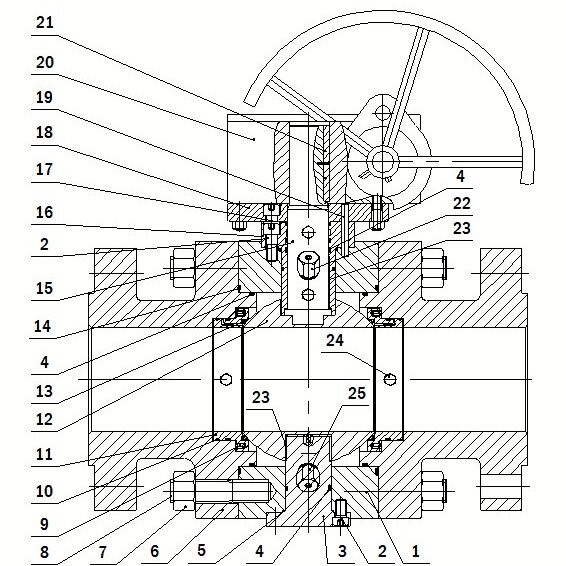

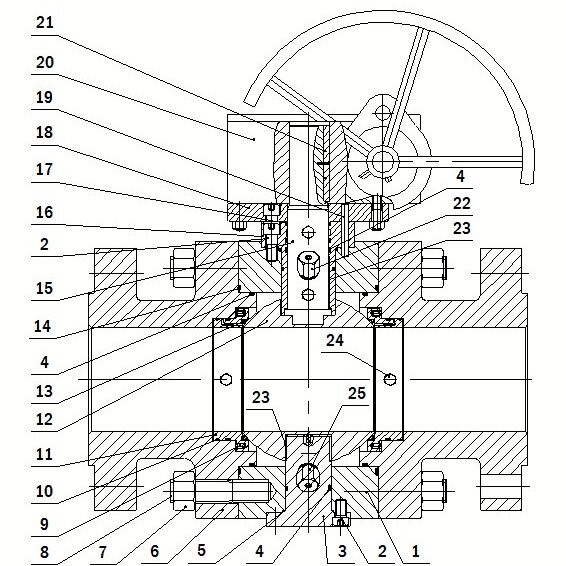

The trunnion mounted ball valve is available in two distinctive body structures – the two-piece and three-piece configurations. The middle flange, connected by bolts, incorporates enhanced polytetrafluoroethylene (PTFE) sealing embedded within a stainless steel ring. A spring behind the steel ring ensures tight contact with the ball, resulting in bidirectional sealing without flow direction restrictions. Typically, these valves are horizontally installed, making them particularly suitable for high-pressure and large-diameter applications.

Trunnion mounted ball valves offer a multitude of advantages, making them a preferred choice in various industrial applications. Here are the key benefits of using trunnion mounted ball valves:

In addition to the core advantages mentioned, trunnion mounted ball valves boast several additional features that contribute to their versatility and reliability in various industrial settings. These features enhance the overall functionality and performance of trunnion mounted ball valves:

The trunnion mounted ball valve's advanced design, coupled with its versatile features, positions it as a reliable and efficient solution for various industrial applications. From its bidirectional sealing capabilities to fire-resistant structures and flexible operation, the trunnion mounted ball valve stands as a testament to innovation in valve technology, meeting the evolving demands of modern pipelines.

The trunnion mounted ball valve is available in two distinctive body structures – the two-piece and three-piece configurations. The middle flange, connected by bolts, incorporates enhanced polytetrafluoroethylene (PTFE) sealing embedded within a stainless steel ring. A spring behind the steel ring ensures tight contact with the ball, resulting in bidirectional sealing without flow direction restrictions. Typically, these valves are horizontally installed, making them particularly suitable for high-pressure and large-diameter applications.

Trunnion mounted ball valves offer a multitude of advantages, making them a preferred choice in various industrial applications. Here are the key benefits of using trunnion mounted ball valves:

1. Ease of Operation: The ball is supported by upper and lower trunnions, reducing friction and eliminating the need for excessive torque caused by pressure. This design enhances operational efficiency.

2. Reliable Sealing Performance: PTFE single-material sealing rings embedded in stainless steel valve seats, coupled with springs, ensure sufficient pre-tightening force, maintaining excellent sealing performance even in the event of wear.

3. Fire-resistant Structure: Compliance with APl 6FA and APl 607 fire resistance standards is achieved through the inclusion of a fire-resistant sealing ring between the ball and the valve seat. This ensures a metal-to-metal seal in case of significant leaks due to sudden heating or a fire.

4. Automatic Pressure Relief Function: An innovative feature allows the valve seat to retract from the ball, achieving automatic pressure relief if abnormal pressure levels are detected beyond the spring's pre-set force.

5. Drainage Path: Both the upper and lower parts of the valve body are equipped with drainage holes, facilitating leakage checks of the valve seat. This feature allows direct replacement of packing and discharge of retained substances during full open or closed positions, reducing medium contamination.

2. Reliable Sealing Performance: PTFE single-material sealing rings embedded in stainless steel valve seats, coupled with springs, ensure sufficient pre-tightening force, maintaining excellent sealing performance even in the event of wear.

3. Fire-resistant Structure: Compliance with APl 6FA and APl 607 fire resistance standards is achieved through the inclusion of a fire-resistant sealing ring between the ball and the valve seat. This ensures a metal-to-metal seal in case of significant leaks due to sudden heating or a fire.

4. Automatic Pressure Relief Function: An innovative feature allows the valve seat to retract from the ball, achieving automatic pressure relief if abnormal pressure levels are detected beyond the spring's pre-set force.

5. Drainage Path: Both the upper and lower parts of the valve body are equipped with drainage holes, facilitating leakage checks of the valve seat. This feature allows direct replacement of packing and discharge of retained substances during full open or closed positions, reducing medium contamination.

In addition to the core advantages mentioned, trunnion mounted ball valves boast several additional features that contribute to their versatility and reliability in various industrial settings. These features enhance the overall functionality and performance of trunnion mounted ball valves:

- Emergency Grease Injection for Tight Sealing: A grease injection valve and grease gun enable quick injection of grease into the sealing part of the oil injection valve seat in case of unexpected failure, facilitating prompt and leak-free rescue operations.

- Reliable Stem Sealing and Low Operating Torque: Double sealing, including an O-ring seal on the packing gland, ensures reliable stem sealing. Graphite packing injection minimizes post-fire leakage from the stem. Sliding and thrust bearings on the stem contribute to easy valve operation.

- Full or Reduced Bore: The option to choose between full or reduced bore structures based on requirements allows flexibility in pipeline cleaning, with the full-bore valve maintaining a flow diameter consistent with the pipeline diameter.

- Long Stem: The stem's length can be adjusted based on installation and operational needs, making it particularly suitable for buried pipelines such as city gas.

- Flexible Operation: Low-friction, self-lubricating seat and stem bearings significantly reduce the working torque of the valve, enabling flexible and extended operation without the need for frequent sealing grease applications.

The trunnion mounted ball valve's advanced design, coupled with its versatile features, positions it as a reliable and efficient solution for various industrial applications. From its bidirectional sealing capabilities to fire-resistant structures and flexible operation, the trunnion mounted ball valve stands as a testament to innovation in valve technology, meeting the evolving demands of modern pipelines.