Hard Seal Lubricated Plug Valves: Technology and Applications

Hard seal lubricated plug valves have emerged as a cutting-edge solution for applications demanding high working pressures and temperature ranges. This advanced valve technology is broadly classified into conventional lubricated plug valves and pressure-balanced plug valves, both of which leverage specially formulated grease to enhance sealing performance, reduce torque, and extend the valve's operational lifespan.

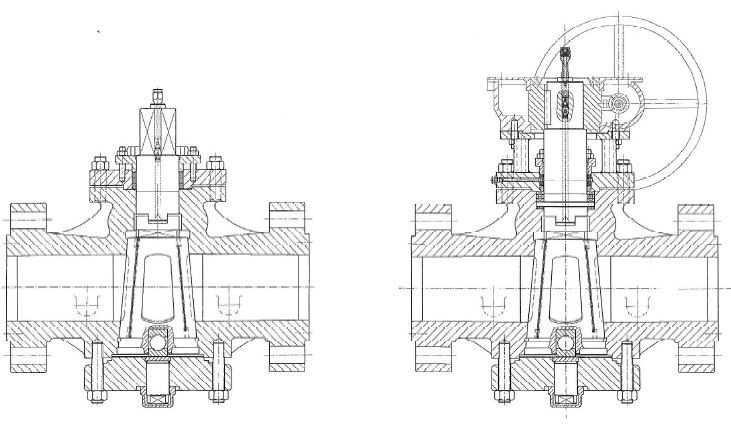

About Conventional Lubricated Plug Valves

This type of valve is distinguished by its unique lubrication system, which enhances sealing capabilities and extends the valve's overall lifespan. In this discussion, we delve into the key features and design aspects of conventional lubricated plug valves.

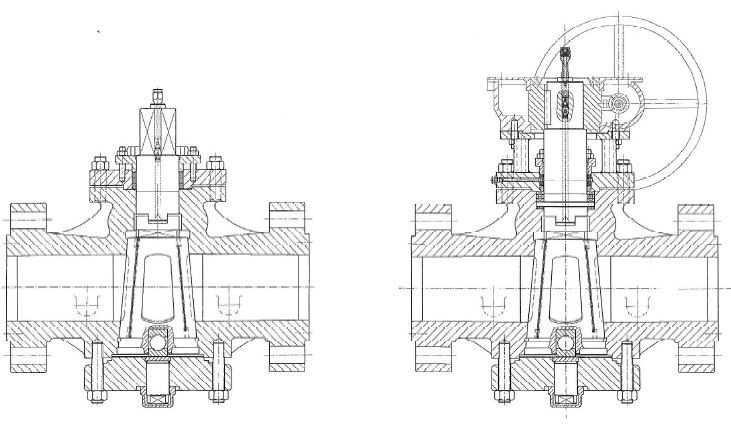

Introducing Pressure-Balanced Plug Valves

Pressure-balanced plug valves introduce innovative features that address challenges associated with torque requirements and sealing efficiency. In this exploration, we delve into the key characteristics and functionalities of pressure-balanced plug valves. In order to further minimize the torque required for opening and closing, the pressure-balanced plug valve is introduced with the following characteristics:

In summary, the application of lubricated hard seal plug valves significantly reduces opening and closing torques, ensuring efficient operation in diverse industrial settings. Selecting the appropriate lubricating grease is paramount to prevent medium contamination based on real-world operating conditions. This advanced valve technology stands out for its exceptional performance and reliability, making it a preferred choice in critical industrial applications.

About Conventional Lubricated Plug Valves

This type of valve is distinguished by its unique lubrication system, which enhances sealing capabilities and extends the valve's overall lifespan. In this discussion, we delve into the key features and design aspects of conventional lubricated plug valves.

Installation and Sealing Structure: The conventional hard seal plug valve is installed in the normal position, utilizing a sealing structure where lubricating grease lubricates the valve seat, reducing friction between the valve body and the plug sealing surface. High-pressure sealing grease forms a film around the plug, facilitating smooth opening and closing.

Optimizing Opening and Closing Forces: To further reduce the torque required for opening and closing, the plug diameter is typically minimized, and a rectangular flow channel design is employed. Although this increases fluid resistance, it effectively reduces the opening and closing forces.

Sealing Material and Surface Treatment: The sealing portion of the plug cone is constructed with STL alloy material through welding or surface hardening technology, enhancing wear resistance and corrosion resistance, thereby extending the valve's service life.

Surface Treatment: The plug cone surface is meticulously polished to a mirror finish, and the sealing surface of the valve body is ground, resulting in lower opening and closing torques.

Optimizing Opening and Closing Forces: To further reduce the torque required for opening and closing, the plug diameter is typically minimized, and a rectangular flow channel design is employed. Although this increases fluid resistance, it effectively reduces the opening and closing forces.

Sealing Material and Surface Treatment: The sealing portion of the plug cone is constructed with STL alloy material through welding or surface hardening technology, enhancing wear resistance and corrosion resistance, thereby extending the valve's service life.

Surface Treatment: The plug cone surface is meticulously polished to a mirror finish, and the sealing surface of the valve body is ground, resulting in lower opening and closing torques.

Introducing Pressure-Balanced Plug Valves

Pressure-balanced plug valves introduce innovative features that address challenges associated with torque requirements and sealing efficiency. In this exploration, we delve into the key characteristics and functionalities of pressure-balanced plug valves. In order to further minimize the torque required for opening and closing, the pressure-balanced plug valve is introduced with the following characteristics:

Installation and Lifting Force: The plug cone is installed in an inverted position, with a check valve located at the upper part. In the closed state, due to the difference in cross-sectional areas, the injected high-pressure sealing grease lifts the plug, achieving better sealing between the plug and the valve body.

Force Balance at the Moment of Opening: Upon opening the valve, the pressure in the lower chamber of the valve body balances with the pressure of the pipeline medium. The high-pressure sealing grease exerts a downward force on the plug, creating a slight gap between the rotating plug and the valve body sealing surface, effectively reducing the torque during plug rotation and protecting the sealing pair.

Coping with High-Temperature Conditions: In high-temperature conditions, the thermal expansion of the plug is absorbed through its up-and-down movement, preventing the wedge lock phenomenon of the sealing pair.

Force Balance at the Moment of Opening: Upon opening the valve, the pressure in the lower chamber of the valve body balances with the pressure of the pipeline medium. The high-pressure sealing grease exerts a downward force on the plug, creating a slight gap between the rotating plug and the valve body sealing surface, effectively reducing the torque during plug rotation and protecting the sealing pair.

Coping with High-Temperature Conditions: In high-temperature conditions, the thermal expansion of the plug is absorbed through its up-and-down movement, preventing the wedge lock phenomenon of the sealing pair.

In summary, the application of lubricated hard seal plug valves significantly reduces opening and closing torques, ensuring efficient operation in diverse industrial settings. Selecting the appropriate lubricating grease is paramount to prevent medium contamination based on real-world operating conditions. This advanced valve technology stands out for its exceptional performance and reliability, making it a preferred choice in critical industrial applications.