The Essential Role and Maintenance of Y Strainers

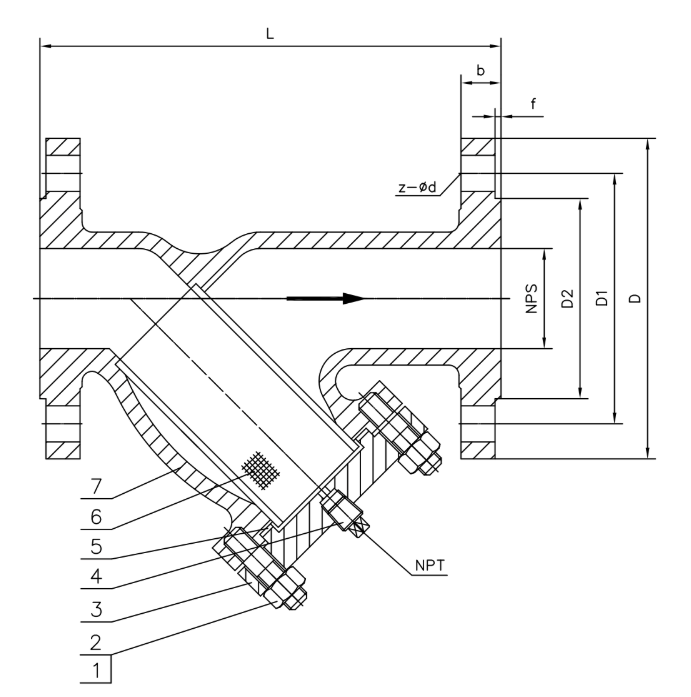

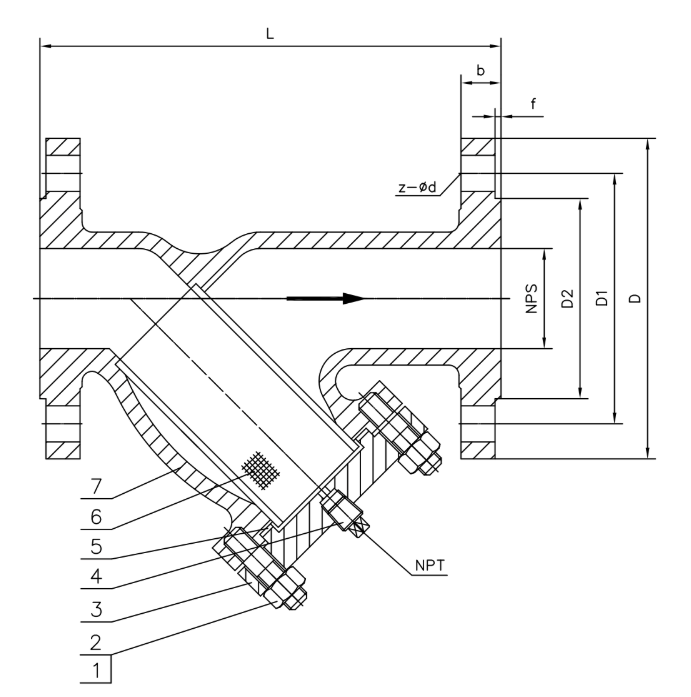

Y strainers refer to the strainer in the shape of letter "y", serving as a pivotal component in preserving the operational integrity of fluid transportation systems by effectively eliminating minute solid particles. These strainers act as guardians of equipment functionality, preventing impurities from compromising crucial valves and components. Installed typically at the inlets of pressure-reducing valves, pressure relief valves, water level valves, and other equipment, Y strainers are indispensable for purging contaminants and ensuring the smooth operation of valves and devices.

Principle of Operation

As the fluid flows into the filter housing through a designated mesh screen, solid impurities are effectively blocked, permitting only clean liquid to exit through the filter outlet. To simplify maintenance, the detachable filter mesh can be easily removed for cleaning and subsequently reinstalled as required.

Cleaning Process for Y Strainers

Installation Guidelines for Y Strainers

Adopting these practices boosts the reliability and efficiency of Y strainers, contributing to the overall effectiveness of fluid transportation systems. Regular maintenance guarantees extended service life and uninterrupted operation, establishing Y strainers as indispensable components in various industrial applications.

Principle of Operation

As the fluid flows into the filter housing through a designated mesh screen, solid impurities are effectively blocked, permitting only clean liquid to exit through the filter outlet. To simplify maintenance, the detachable filter mesh can be easily removed for cleaning and subsequently reinstalled as required.

Cleaning Process for Y Strainers

1. Close inlet and outlet valves for the fan coil unit's cooling water. Gradually release water through the exhaust valve, starting from larger to smaller outlets. If the exhaust valve doesn't release water and valves are intact, open the inlet valve to clear debris.

2. Cut open the Y strainer's insulation layer, unscrew the cover, and remove the filter. Collect water, open the outlet valve to back flush dirt in the radiator coil using backflow pressure until water is clear. Close the outlet valve, reinsert the cleaned filter, and seal it with the cover.

3. Open the cooling water inlet valve, let the exhaust valve release air until water flows steadily. Tighten the air vent screw on the exhaust valve and open the outlet valve for the cooling water.

4. Inspect valve connection points for leaks. If no leaks, reinstate the insulation layer for the Y strainer. If leaks occur, address and repair before restoring the insulation layer.

2. Cut open the Y strainer's insulation layer, unscrew the cover, and remove the filter. Collect water, open the outlet valve to back flush dirt in the radiator coil using backflow pressure until water is clear. Close the outlet valve, reinsert the cleaned filter, and seal it with the cover.

3. Open the cooling water inlet valve, let the exhaust valve release air until water flows steadily. Tighten the air vent screw on the exhaust valve and open the outlet valve for the cooling water.

4. Inspect valve connection points for leaks. If no leaks, reinstate the insulation layer for the Y strainer. If leaks occur, address and repair before restoring the insulation layer.

Installation Guidelines for Y Strainers

- Install Y-type water filters horizontally or vertically, aligning the water flow with the arrow direction on the filter body.

- For easy maintenance, pair Y strainers with shut-off valves. Place these valves upstream and downstream, allowing closure during maintenance to isolate the Y strainer.

- Due to higher liquid resistance as it passes through, regular filter cleaning is essential for optimal Y strainer performance.

- To prevent disruptions during maintenance, install a bypass pipe. Keep the shut-off valve on the bypass pipe closed during regular operation, opening it only for Y strainer maintenance.

- Allocate sufficient space during Y strainer installation for hassle-free maintenance.

Adopting these practices boosts the reliability and efficiency of Y strainers, contributing to the overall effectiveness of fluid transportation systems. Regular maintenance guarantees extended service life and uninterrupted operation, establishing Y strainers as indispensable components in various industrial applications.