Exploring the Benefits and Considerations of Plug Valves in Chemical Applications

The demands for valve performance in the chemical industry are exceptionally high, particularly when handling corrosive media. In this context, plug valves have gradually emerged as the ideal valves in chemical processes due to their unique design and superior performance. This article delves into the design features, advantages, and potential challenges faced by plug valve in specific applications.

Major Advantages of Plug Valves

Plug valves, characterized by their unique design and functionality, offer a range of advantages that make them a preferred choice in various industrial applications. Understanding these advantages is crucial for industries seeking reliable and efficient valve solutions. Here are the key advantages of plug valves:

Several Considerations about Plug Valves

While plug valves offer a myriad of advantages, it is crucial to carefully consider certain aspects to ensure their optimal performance and longevity in industrial applications. Understanding these considerations is essential for industries contemplating the adoption of plug valves. Here are the key considerations associated with plug valves:

Despite facing challenges such as increased torque requirements, plug valves stand out as a reliable choice in the chemical industry due to their comprehensive performance and dependability. As awareness of their advantages grows among users, plug valves are poised to play an increasingly vital role in chemical processes, continuing to provide efficient and dependable valve solutions for the industry.

Major Advantages of Plug Valves

Plug valves, characterized by their unique design and functionality, offer a range of advantages that make them a preferred choice in various industrial applications. Understanding these advantages is crucial for industries seeking reliable and efficient valve solutions. Here are the key advantages of plug valves:

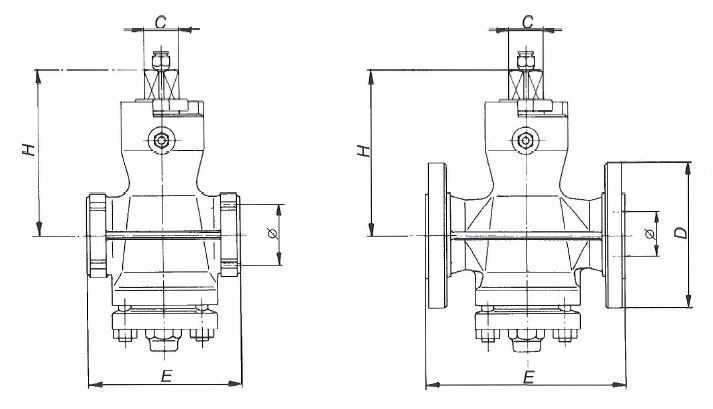

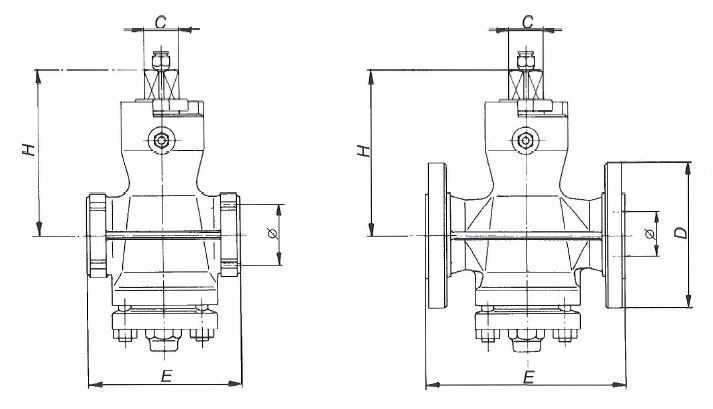

Design Features: The valve body adopts an integrated top-mounted design, ensuring a simple structure that facilitates easy online maintenance while guaranteeing leak-free performance and high pipeline system strength.

Corrosion Resistance: In chemical processes where media exhibit strong corrosiveness, plug valves, with their g-grade cast body, demonstrate resistance to intergranular corrosion. The casting quality is rated as level two, with precision reaching level five.

Liner Cover Design: The opening and closing parts (plugs) are entirely covered by the liner, preventing wear and tear on the valve body and plug. The liner and top seal are easily replaceable, enabling efficient maintenance and updates for up to 300 valves.

Versatile Customization: Plug valves can be tailored to execute specific functions based on user requirements, adapting to various configurations such as three-way, four-way, five-way, six-way, double valve groups, or multiple valve groups, along with accommodating diverse jacketing requirements. This adaptability suits a wide range of industrial scenarios.

Superior Sealing Performance: Plug valves exhibit excellent surface sealing, making them suitable for handling harsh media like corrosive fluids and sediments containing catalytic particles.

Wide Applicability: Plug valves find applications in a variety of corrosive, abrasive, toxic, and continuous operation media and equipment, offering advantages in the chemical industry.

Longevity and Reliability: Featuring a long lifespan and high reliability, plug valves meet the "zero leakage" test requirements of API 598 soft-seated valves and comply with TA-Luft or ISO 15848 requirements for stem sealing.

Corrosion Resistance: In chemical processes where media exhibit strong corrosiveness, plug valves, with their g-grade cast body, demonstrate resistance to intergranular corrosion. The casting quality is rated as level two, with precision reaching level five.

Liner Cover Design: The opening and closing parts (plugs) are entirely covered by the liner, preventing wear and tear on the valve body and plug. The liner and top seal are easily replaceable, enabling efficient maintenance and updates for up to 300 valves.

Versatile Customization: Plug valves can be tailored to execute specific functions based on user requirements, adapting to various configurations such as three-way, four-way, five-way, six-way, double valve groups, or multiple valve groups, along with accommodating diverse jacketing requirements. This adaptability suits a wide range of industrial scenarios.

Superior Sealing Performance: Plug valves exhibit excellent surface sealing, making them suitable for handling harsh media like corrosive fluids and sediments containing catalytic particles.

Wide Applicability: Plug valves find applications in a variety of corrosive, abrasive, toxic, and continuous operation media and equipment, offering advantages in the chemical industry.

Longevity and Reliability: Featuring a long lifespan and high reliability, plug valves meet the "zero leakage" test requirements of API 598 soft-seated valves and comply with TA-Luft or ISO 15848 requirements for stem sealing.

Several Considerations about Plug Valves

While plug valves offer a myriad of advantages, it is crucial to carefully consider certain aspects to ensure their optimal performance and longevity in industrial applications. Understanding these considerations is essential for industries contemplating the adoption of plug valves. Here are the key considerations associated with plug valves:

Increased Torque Requirements: The surface sealing design raises the demand for drive torque, potentially increasing costs for pneumatic actuators with larger accessories.

Improper Liner Material Selection: In certain applications, improper liner material selection or inadequate valve body design may lead to the expansion of polytetrafluoroethylene (PTFE) liners, causing multiple changes in the required drive torque. Careful material selection minimizes such occurrences.

Higher Initial Investment: The initial investment for plug valves is relatively higher. However, as users increasingly accept their reliability and consider the overall lifecycle costs, the inclination to switch to ball valves diminishes.

Improper Liner Material Selection: In certain applications, improper liner material selection or inadequate valve body design may lead to the expansion of polytetrafluoroethylene (PTFE) liners, causing multiple changes in the required drive torque. Careful material selection minimizes such occurrences.

Higher Initial Investment: The initial investment for plug valves is relatively higher. However, as users increasingly accept their reliability and consider the overall lifecycle costs, the inclination to switch to ball valves diminishes.

Despite facing challenges such as increased torque requirements, plug valves stand out as a reliable choice in the chemical industry due to their comprehensive performance and dependability. As awareness of their advantages grows among users, plug valves are poised to play an increasingly vital role in chemical processes, continuing to provide efficient and dependable valve solutions for the industry.