Efficiency and Versatility of Pneumatic Three-Piece Ball Valve Systems

Pneumatic three-piece ball valves represent an efficient valve system, incorporating a three-piece ball valve paired with a pneumatic actuator. This ball valve boasts rapid execution speed, eliminating the need for manual operation, significantly enhancing efficiency, saving on labor and time costs, and concurrently reducing the opening and closing time of the ball valve.

Types of Pneumatic Three-Piece Ball Valves

There are three main types of commonly used pneumatic three-piece ball valves. Firstly, the pneumatic three-piece ball valve utilizing the GTD series pneumatic actuator is the most prevalent type. Secondly, valves equipped with the ATD pneumatic actuator excel in process precision, superior materials, and aesthetic appeal, gradually replacing the GTD series despite a slightly higher price. The third type is the pneumatic three-piece flanged ball valve, which adds flanges to the three-piece ball valve. Despite its larger size, it is used less frequently.

Its Working Principle

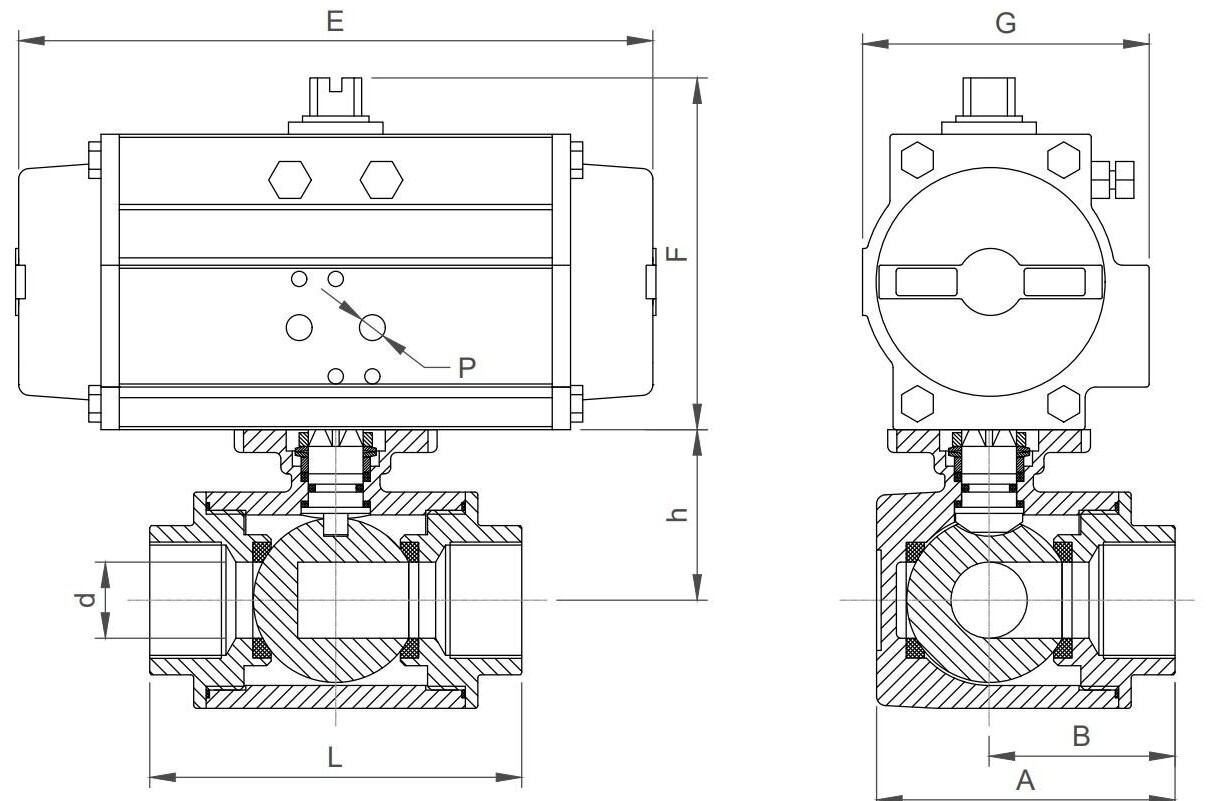

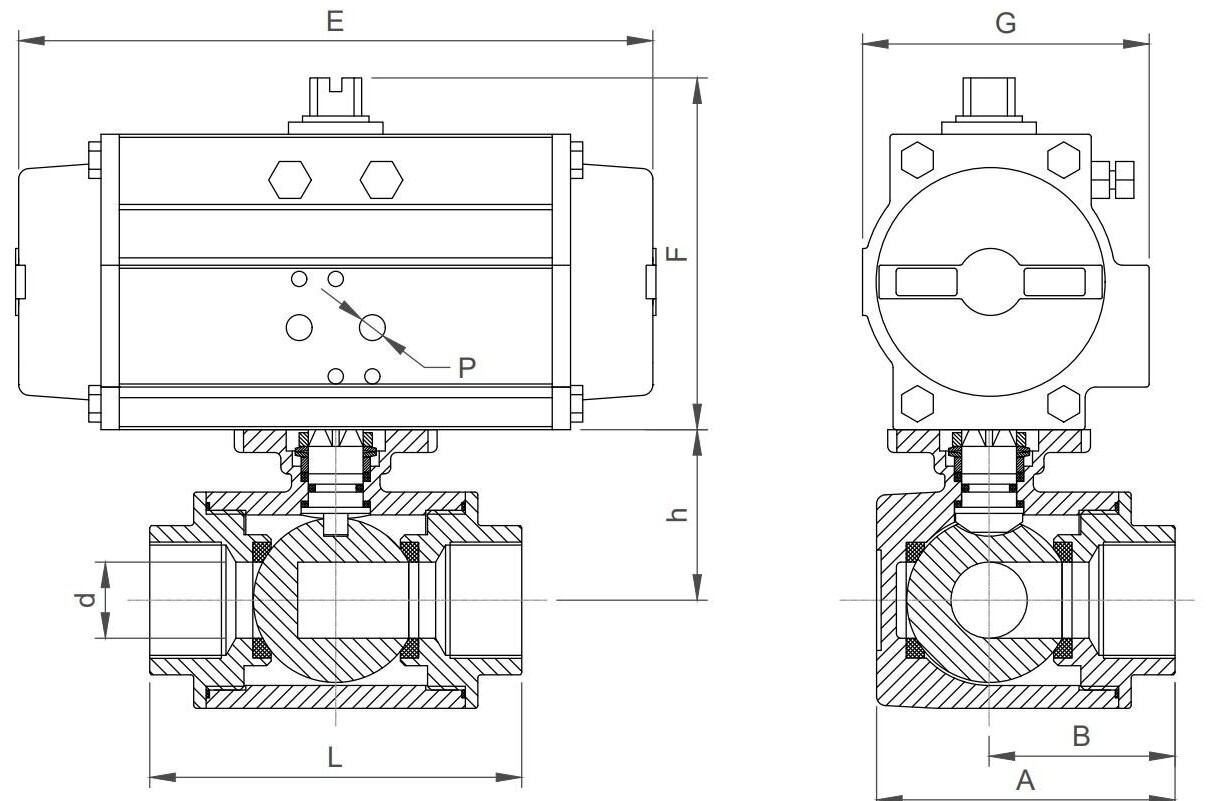

The working principle of pneumatic three-piece ball valves involves rotating 90 degrees through a pneumatic actuator and applying a small torque to achieve tight closure. The valve body's internal chamber is designed to be entirely equal, providing minimal resistance and a straight-through flow path. This design makes pneumatic three-piece ball valves suitable for general working media and harsh working conditions. The valve body can be integral or modular.

As an evolution of threaded ball valves, the working principle of pneumatic three-piece ball valves is similar, achieving valve opening and closing by rotating the valve core. It features a compact structure, easy operation, and maintenance, and finds extensive applications in various industries, such as petroleum, chemical, power generation, papermaking, atomic energy, aviation, and daily life.

The Advantages and Applications

Pneumatic three-piece ball valves, as a new type of valve, have demonstrated numerous advantages in recent years. Specifically, they exhibit low fluid resistance, simple structure, small size, light weight, convenient operation, and easy maintenance, making them widely applicable across different fields. This valve system can effectively isolate media in fully open or fully closed positions, ensuring sealing performance. Overall, pneumatic three-piece ball valves play a crucial role in modern industry and daily life.

In conclusion, the pneumatic three-piece ball valve system has become an indispensable component in various industries, offering efficiency, versatility, and reliable performance. As technology continues to advance, these valves are expected to further contribute to the optimization of processes and systems across different sectors.

Types of Pneumatic Three-Piece Ball Valves

There are three main types of commonly used pneumatic three-piece ball valves. Firstly, the pneumatic three-piece ball valve utilizing the GTD series pneumatic actuator is the most prevalent type. Secondly, valves equipped with the ATD pneumatic actuator excel in process precision, superior materials, and aesthetic appeal, gradually replacing the GTD series despite a slightly higher price. The third type is the pneumatic three-piece flanged ball valve, which adds flanges to the three-piece ball valve. Despite its larger size, it is used less frequently.

Its Working Principle

The working principle of pneumatic three-piece ball valves involves rotating 90 degrees through a pneumatic actuator and applying a small torque to achieve tight closure. The valve body's internal chamber is designed to be entirely equal, providing minimal resistance and a straight-through flow path. This design makes pneumatic three-piece ball valves suitable for general working media and harsh working conditions. The valve body can be integral or modular.

As an evolution of threaded ball valves, the working principle of pneumatic three-piece ball valves is similar, achieving valve opening and closing by rotating the valve core. It features a compact structure, easy operation, and maintenance, and finds extensive applications in various industries, such as petroleum, chemical, power generation, papermaking, atomic energy, aviation, and daily life.

The Advantages and Applications

Pneumatic three-piece ball valves, as a new type of valve, have demonstrated numerous advantages in recent years. Specifically, they exhibit low fluid resistance, simple structure, small size, light weight, convenient operation, and easy maintenance, making them widely applicable across different fields. This valve system can effectively isolate media in fully open or fully closed positions, ensuring sealing performance. Overall, pneumatic three-piece ball valves play a crucial role in modern industry and daily life.

In conclusion, the pneumatic three-piece ball valve system has become an indispensable component in various industries, offering efficiency, versatility, and reliable performance. As technology continues to advance, these valves are expected to further contribute to the optimization of processes and systems across different sectors.