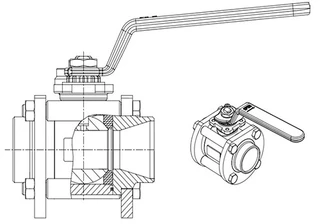

Key Considerations and Practical Guidance for Ball Valve Selection

Ball valves are indispensable components in various fluid control systems, playing a critical role in ensuring pipeline system safety, efficiency, and cost-effectiveness. Choosing the most suitable ball valve involves considering several factors. The following provides a comprehensive overview based on case studies of ball valve applications in water supply systems: 1. Applicable Media and Operating Conditions Ball valves are versatile and suitable for diverse operating conditions,...