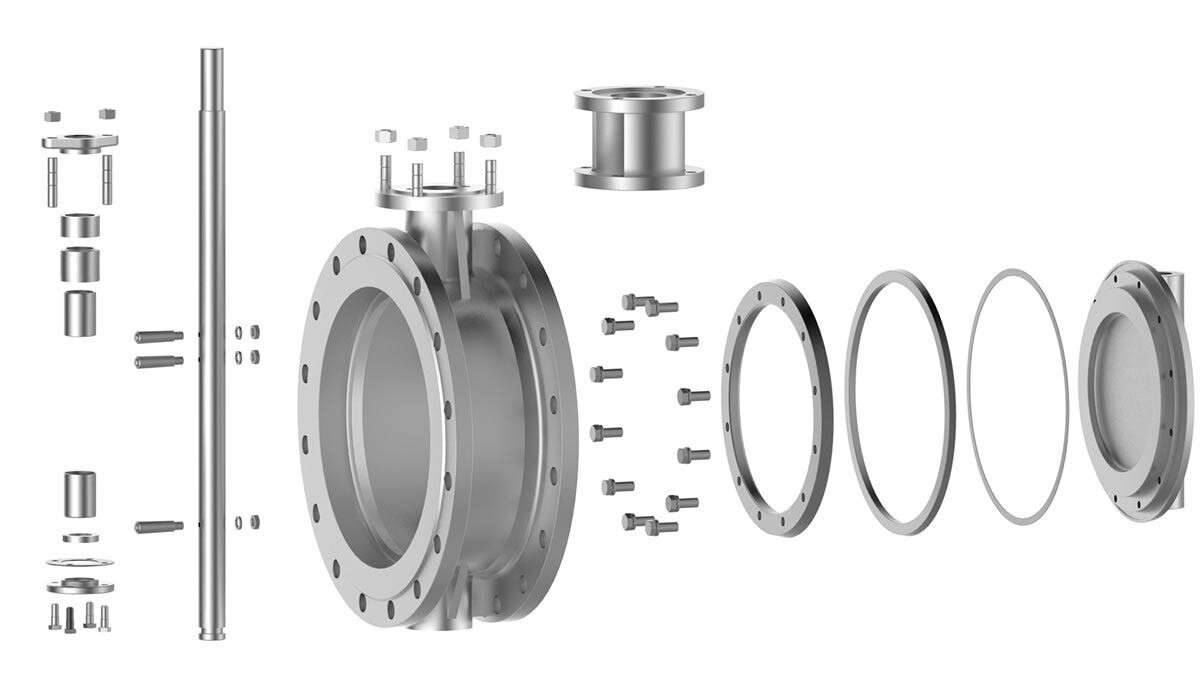

Quick Guide to Butterfly Valve Seal Replacement

On this page

The butterfly valve plays a crucial role in industrial pipeline systems, and the condition of its seals is paramount for proper functioning. When seals become damaged or aged, timely replacement becomes a necessary maintenance measure. Below, we will provide a detailed overview of the steps and considerations involved in replacing the seal of a butterfly valve.

Before starting the seal replacement process, it's essential to prepare carefully:

Marking Positions: Use paint or a marker to label key spots on the butterfly plate and seal pressure plate. These marks will help align everything correctly later.

Valve Safety: Make sure the butterfly valve is fully open at a 90-degree angle. Turn off the power and assign someone to watch for accidental valve movement.

Taking out the old seal requires careful steps and safety measures:

Unscrewing: Use an Allen wrench to loosen all screws holding the seal pressure plate. Keep them safe in a container.

Stay Safe: Larger butterfly valves have heavy seal pressure plates. Be careful not to get hurt while removing them.

Now it's time to replace the old seal with a new one:

Gently remove the old rubber seal from the butterfly plate. Take care not to damage it.

Fit the new seal in place, making sure it sits properly and aligns with the valve.

Getting the seal pressure plate back in place requires attention to detail:

Aligning Properly: Using the marks made earlier, fit the seal pressure plate onto the butterfly plate correctly.

Tightening Up: Secure the seal pressure plate with all the screws you removed earlier. Make sure they're all tight to keep everything in place.

After replacing the seal, it's essential to inspect and tidy up:

Look Over Carefully: Check both the seal and pressure plate for any issues. They should be properly aligned and secure.

Cleaning Up: Clean all tools and equipment used during the replacement. Ensure no debris is left behind in the pipeline.

While butterfly valve seal replacement may seem straightforward, strict adherence to procedures is necessary, with particular attention to safety. Timely seal replacement ensures the sealing performance and stability of the butterfly valve, prolonging its service life and safeguarding the safety of pipeline systems.