Comparing Single Plate and Dual Plate Check Valves

On this page

Single plate check valves and dual plate check valves are two common types of valves in pipeline systems, playing a crucial role in controlling the direction of fluid flow. Despite their similar basic principles, there are significant differences in structure, functionality, and applicability, which affect their selection and application in various engineering projects.

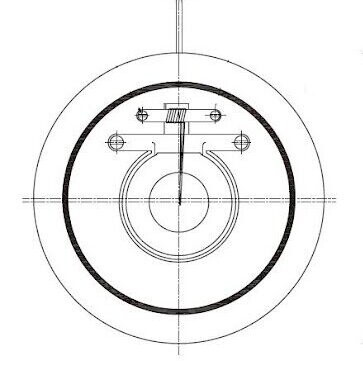

Single plate check valves typically consist of a single plate fixed on the valve cover, operated by the rotation of the plate to open and close the valve. When fluid flows in the forward direction, the plate rotates upward, opening the valve to allow fluid passage. Conversely, when fluid flows in the reverse direction, the plate rotates downward under the force of the fluid, closing the valve to prevent backflow.

1. Advantages:

Simple structure, easy maintenance, and good reliability.

Effective for low flow rates and high-pressure pipeline systems.

2. Disadvantages:

Incomplete closure may lead to potential leakage.

Slower closing speed under high-speed fluid or high-flow conditions may impact the operational efficiency of the pipeline system.

Simple structure, easy maintenance, and good reliability.

Effective for low flow rates and high-pressure pipeline systems.

2. Disadvantages:

Incomplete closure may lead to potential leakage.

Slower closing speed under high-speed fluid or high-flow conditions may impact the operational efficiency of the pipeline system.

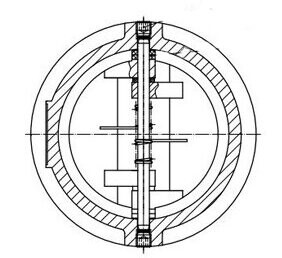

Dual plate check valves consist of two plates fixed on the valve body, operated by rotation to open and close the valve. Compared to single plate valves, dual plate check valves double the number of plates, providing more thorough closure.

1. Advantages:

More thorough closure, effectively preventing leakage.

Suitable for high flow rates and high-pressure pipeline systems, with strong pressure resistance and flow control capability.

2. Disadvantages:

Relatively complex structure and higher manufacturing costs.

May produce noise and vibration during reverse flow.

More thorough closure, effectively preventing leakage.

Suitable for high flow rates and high-pressure pipeline systems, with strong pressure resistance and flow control capability.

2. Disadvantages:

Relatively complex structure and higher manufacturing costs.

May produce noise and vibration during reverse flow.

Choosing Between Single Plate and Dual Plate Check Valves

When selecting the appropriate check valve, the following factors need to be considered:

- Operating conditions of the pipeline system, including fluid characteristics, flow rate, and pressure.

- For low flow rates and low pressure conditions, single plate check valves can meet requirements with lower costs and simpler maintenance.

- For high flow rates and high-pressure systems, especially those requiring stricter fluid control and leakage prevention, dual plate check valves are a better choice despite their higher manufacturing costs.

- Additionally, the direction of fluid flow in the pipeline system needs to be considered. If fluid only needs to flow in a single direction, single plate check valves are a good choice. However, if control is needed for bidirectional flow, dual plate check valves are more applicable.

In summary, single plate check valves and dual plate check valves have their own advantages and disadvantages in pipeline systems, suitable for different operating conditions. When selecting the appropriate check valve, it is essential to consider factors such as the operating conditions of the pipeline system, fluid characteristics, and flow direction. Whether single plate or dual plate check valves, they both play crucial roles in ensuring the safe and stable operation of pipeline systems.