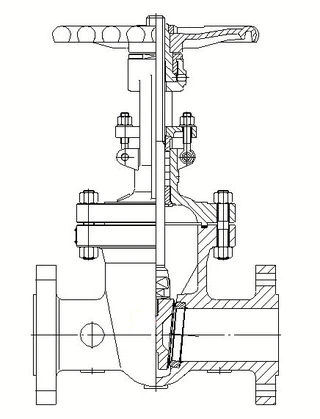

Troubleshooting Forged Steel Check Valve Failures

Forged steel check valves are essential components in pipeline systems, serving to control the direction of fluid flow and prevent backflow, thereby ensuring the smooth operation of systems. However, due to prolonged use or other factors, forged steel check valves may experience various failures, affecting their normal functions. This article provides a detailed overview of common failures and their corresponding solutions, aiming to help users better address issues and ensure the stable...