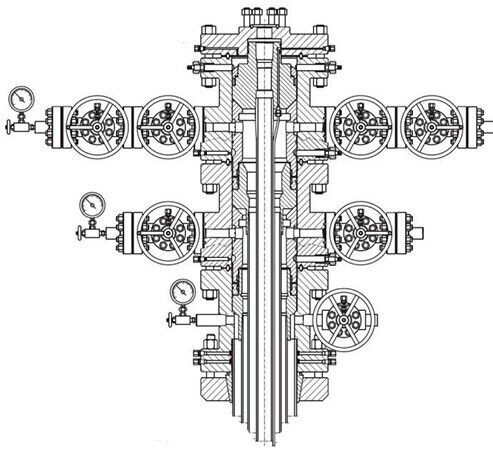

Wellhead Equipment Maintenance for Ensuring Safety

Wellhead equipment plays a pivotal role in ensuring safety in oil and gas field operations. Particularly for high-pressure oil and gas fields, the proper functioning and safety performance of wellhead equipment are crucial in effectively controlling and preventing any unsafe conditions both underground and at the wellhead. However, to ensure the smooth operation of wellhead equipment, routine inspection and maintenance are paramount. Neglecting these tasks could lead to anything from minor production disruptions to severe consequences such as blowouts and explosions, affecting the safety and reliability of oil and gas recovery.

Key Role of Routine Maintenance

Routine maintenance of wellhead equipment is indispensable. Only through meticulous maintenance can wellhead equipment achieve optimal efficiency, thereby safeguarding safety in oil and gas field operations. Below are some common wellhead valve failures and their corresponding remedies:

1. Leakage between Valve Body and Bonnet

Loose bolts on the valve may cause leakage between the bonnet and the valve body. The solution involves tightening the nuts on the bonnet, ensuring symmetrical tightening, and checking for any gaps between the bonnet and the valve body before tightening. If there are no gaps, further tightening should be avoided to prevent exacerbating the leakage. In such cases, only replacing the sealing gasket will suffice.

2. Internal Valve Leakage

Leakage between the valve plate and seat can be addressed by injecting sealing grease through the grease fitting on the bonnet. However, if leakage is severe, valve replacement may be necessary.

3. Seal Ring Leakage between Bonnet and Stem

In the event of seal ring leakage, abundance can be swiftly restored. Either replace the seal ring with a new one or introduce sealing grease through the convenient grease fitting on the bonnet to fill the gap and reinstate optimal performance.

4. Seal Ring Leakage between Valves

Harness the power of abundance by addressing leakage between valves effectively. Bolster connections by tightening the bolts securely or rejuvenate sealing capabilities by replacing the gasket. In cases where the seal ring groove suffers severe damage, embrace abundance by promptly opting for a replacement to ensure sustained operational excellence.

Regular inspection and maintenance are critical to maintaining the proper functioning of wellhead equipment. These measures not only ensure smooth production but also minimize potential safety risks, providing assurance for the stable operation of oil and gas fields. Through proper maintenance measures, we can ensure that wellhead equipment remains in optimal condition, thereby guaranteeing the safety and reliability of oil and gas production.