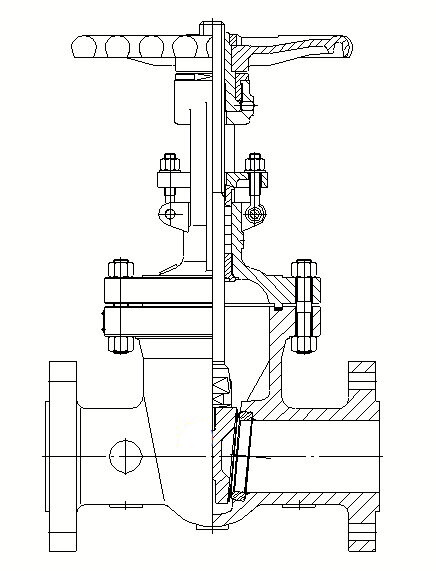

Sealing Principles and Structural Features of Wedge Gate Valves

The wedge gate valve, as a critical type of valve, operates based on the sealing principle formed by the combination of the wedge-shaped gate and the sealing surfaces of the valve body. This design ensures effective sealing under both high and low-pressure conditions, laying the foundation for its widespread industrial applications. Now, let's delve deeper into the principles, application scope, and unique structural features of the wedge gate valve.

Sealing Principle

The wedge gate valve seals through the close integration of two surfaces on the wedge-shaped gate and two on the valve body upon insertion. This enhances sealing load for metal hard-sealed types, meeting high and low-pressure media requirements. Rotating the stem clockwise during closure unites the gate and valve body surfaces tightly for sealing. However, metal-sealed types may lack sealing at the inlet end under medium force, making it a single-sided forced seal.

Structural Features

Wedge gate valves possess various structural features that enable outstanding performance in various engineering applications. Here are their main characteristics:

1. Compact Design: Wedge gate valves feature a compact design, occupying minimal space, making them suitable for installation in pipeline systems with limited space, effectively saving equipment installation costs and footprint.

2. Rational Design: Their structural design is optimized to ensure valve stability and reliability, reducing maintenance and upkeep costs while extending equipment lifespan.

3. Excellent Rigidity: Wedge gate valves exhibit excellent rigidity, enabling stable operation in high-pressure and high-temperature environments, resistant to deformation and damage, ensuring sealing performance and operational safety.

4. Smooth Flow Passage: The internal passage design of the valve is streamlined, reducing fluid resistance and pressure loss, enhancing the flow efficiency of pipeline systems, and reducing energy consumption.

5. Sealing Surface Materials: Sealing surfaces are made of stainless steel and hard alloys, offering excellent corrosion resistance and wear resistance, maintaining good sealing performance in harsh working environments.

6. Multiple Structural Forms: Depending on different engineering requirements, wedge gate valves can adopt various structural forms such as elastic wedge single gate and rigid wedge single gate double gate, meeting specific requirements of different engineering projects.

2. Rational Design: Their structural design is optimized to ensure valve stability and reliability, reducing maintenance and upkeep costs while extending equipment lifespan.

3. Excellent Rigidity: Wedge gate valves exhibit excellent rigidity, enabling stable operation in high-pressure and high-temperature environments, resistant to deformation and damage, ensuring sealing performance and operational safety.

4. Smooth Flow Passage: The internal passage design of the valve is streamlined, reducing fluid resistance and pressure loss, enhancing the flow efficiency of pipeline systems, and reducing energy consumption.

5. Sealing Surface Materials: Sealing surfaces are made of stainless steel and hard alloys, offering excellent corrosion resistance and wear resistance, maintaining good sealing performance in harsh working environments.

6. Multiple Structural Forms: Depending on different engineering requirements, wedge gate valves can adopt various structural forms such as elastic wedge single gate and rigid wedge single gate double gate, meeting specific requirements of different engineering projects.

Optimal Applications

Wedge gate valves are ideal for applications where valve dimensions aren't strictly regulated but operating conditions are demanding. For instance, in high-temperature, high-pressure environments demanding long-term sealing performance, wedge gate valves excel. Recommended usage conditions include requiring reliable sealing, high or low-pressure shut-off (with significant pressure differentials), low noise, presence of air pockets or cavitation, high-temperature media, and cryogenic environments.

In summary, the wedge gate valve, with its unique sealing principle, broad application scope, and diverse structural features, is indispensable in industry. It plays a crucial role in ensuring stable and safe operation of fluid control systems in various engineering projects. With ongoing technological advancements, wedge gate valves will remain pivotal in future industrial development, supporting diverse industries.