How to Prevent and Handle Gate Valve Leaks

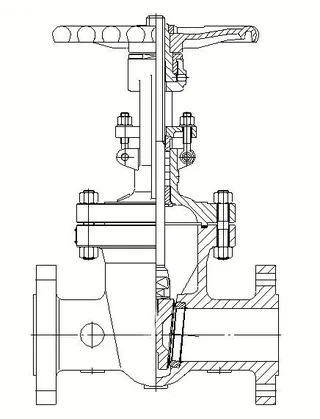

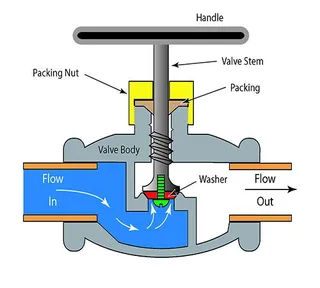

Ensuring the prevention of leaks is crucial in the operation and maintenance of any industrial equipment. Within gate valve systems, inspecting and addressing leakage issues is particularly indispensable. This article will focus on how to inspect gate valves and connecting bolts, handle leaks in valve covers, valve body leaks, and leaks between valve seats and discs, to help ensure the smooth and safe operation of systems. 1. Inspecting Gate Valves and Connecting Bolts Firstly,...