Triple Eccentric Butterfly Valves: Industrial Sealing Excellence

On this page

In industrial pipeline systems, triple eccentric butterfly valves are highly regarded for their unique sealing structure and outstanding performance. Their working principles and structural characteristics make them excel in various working conditions. In this article, we delve deeper into the working principles of triple eccentric butterfly valves and explore their advantages.

Triple eccentric butterfly valves adopt a unique sealing structure, with the sealing surface being a slant cone. The butterfly disc and the sealing ring on the valve seat make face contact. By operating the transmission device to drive the butterfly disc movement, the movement of the disc ensures full contact between the sealing ring and the valve seat, achieving sealing through elastic deformation. Compared to traditional position seals, triple eccentric butterfly valves use torque seals, where the contact pressure between the butterfly disc sealing surface and the valve seat achieves sealing effects. This improvement effectively addresses the issue of large leakage in metal valve seats. Additionally, because the contact pressure is proportional to the medium pressure, triple eccentric butterfly valves possess strong resistance to high pressure and high temperature.

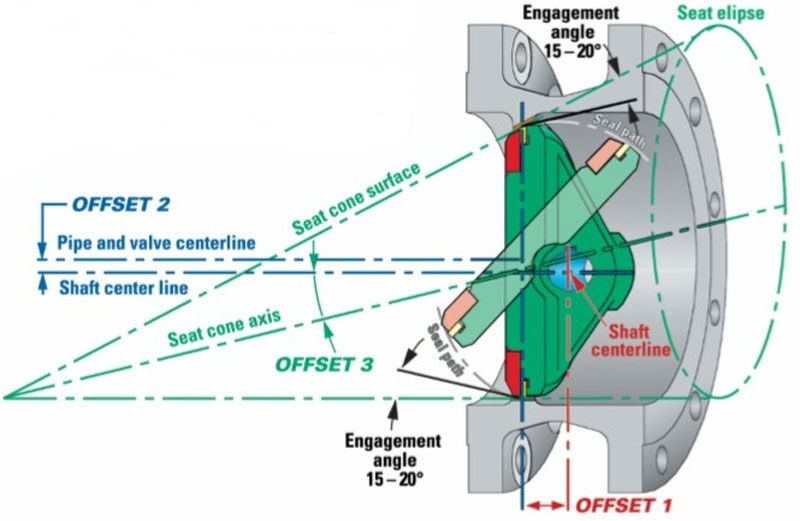

The name "triple eccentric" comes from its three eccentric designs, including:

- The first eccentric: the deviation from the sealing surface to the valve stem centerline.

- The second eccentric: the distance from the valve body centerline to the valve stem centerline.

- The third eccentric: the angle between the centerline of the cone surface where the valve body sealing surface is located and the centerline of the valve body passage.

Triple eccentric butterfly valves have multiple advantages due to their unique design and outstanding performance:

- Excellent sealing performance: By adopting slant cone sealing design and torque sealing principle, triple eccentric butterfly valves achieve excellent sealing effects. Compared to traditional position seals, their sealing is more reliable, effectively reducing leakage risks and ensuring the safe operation of pipeline systems.

- High temperature and high pressure resistance: The use of corrosion-resistant alloy materials welded on the valve seat surface, combined with the contact pressure proportional to the medium pressure, gives triple eccentric butterfly valves excellent resistance to high temperature and high pressure. They can operate stably and reliably even in harsh conditions.

- Convenient and labor-saving operation: The design of the triple eccentric structure reduces friction between the butterfly disc and the valve body sealing surface. This allows the butterfly disc to quickly detach from or release the valve seat during opening or closing, reducing the torque required for operation and making operation more convenient and labor-saving.

- Long service life: By reducing the friction between the butterfly disc and the valve body sealing surface and increasing the service life of the butterfly valve sealing surface, triple eccentric butterfly valves have a long service life. Moreover, the use of corrosion-resistant alloy materials improves the durability of the valve and reduces maintenance costs.

In conclusion, triple eccentric butterfly valves, with their unique sealing structure and outstanding performance, have become an essential component in industrial pipeline systems. Understanding their working principles provides us with deeper insights, while their advantages provide reliable protection for industrial production. With the continuous advancement of technology, we believe that triple eccentric butterfly valves will continue to play an important role in ensuring the safe operation and efficiency improvement of industrial pipeline systems.