Addressing the Lining Issues of Plug Valves

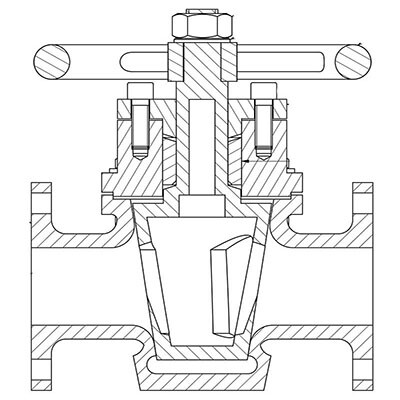

In industrial production, plug valves are indispensable, regulating process flow with precision. However, their vital role is often threatened by lining issues, such as detachment and tearing, which compromise stability and safety. Cold flow, unstable operations, and partial valve opening are primary culprits. Understanding and addressing these challenges are essential for bolstering the reliability and efficiency of plug valves. Let's explore their causes and solutions to ensure seamless industrial operations.

1. Cold Flow Leading to Lining Detachment

One of the fundamental reasons for lining detachment is the phenomenon of cold flow. Especially in the case of plug valves used under specific process conditions, they are more susceptible to the effects of cold flow. Prolonged storage and the accumulation of stress during installation can lead to deformation and detachment of the lining. Therefore, measures need to be taken to avoid exerting excessive stress on the lining during storage and installation, ensuring its integrity and stability.

2. Unstable Operations Resulting in Lining Misalignment

Improper operation is also a significant cause of lining damage. Frequent opening and closing operations can increase the friction between the lining and the plug, resulting in misalignment and damage to the lining. To address this issue, operators need to apply force evenly during use and use appropriate tools to ensure uniform force transmission, thereby reducing the likelihood of lining damage.

3. Partial Valve Opening Leading to Lining Deformation

During the system's trial run and tuning phase, adjustments to the valve opening are necessary to control the flow rate. However, since plug valves are primarily used for fluid cutoff rather than flow regulation, partially opening the valve may lead to lining deformation and damage. Therefore, coordination between control room and field personnel is essential during the tuning process to adjust the valve opening appropriately, ensuring the stability and safety of system operation.

Addressing the lining issues of plug valves is a critical step in ensuring smooth industrial production. By conducting a thorough analysis of the root causes of lining detachment and tearing, and implementing corresponding solutions, we can effectively enhance the reliability and stability of plug valves, ensuring the smooth progress of process flow and providing a solid guarantee for the safety and efficiency of industrial production.