A Comparative Analysis of Flat Gate Valve and Knife Gate Valve

On this page

Flat gate valves and knife gate valves are two widely used types of gate valves in pipeline systems, each with unique designs and functions. Their performance directly affects the efficiency and safety of the system. There are significant differences between these two types of gate valves in terms of structure, application scenarios, and performance. Understanding the differences between these two typical gate valves can provide reasonable guidance when selecting the appropriate valve type for different environments.

In valve design, flat gate valves and knife gate valves each have their distinctive structural features. These features not only determine their application scenarios but also affect their performance and maintenance requirements. Here is a detailed comparison of the structural features of flat gate valves and knife gate valves.

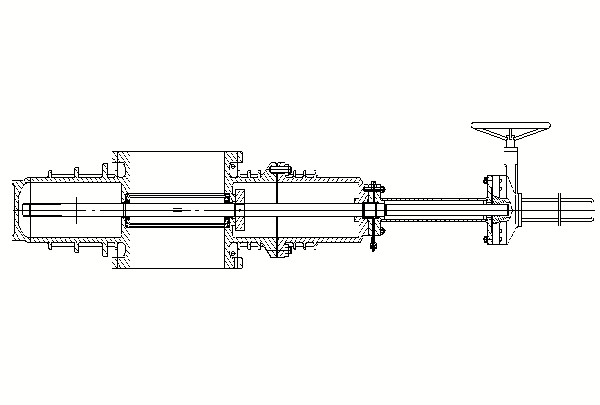

Slat Design: The slat of a flat gate valve is flat and can be completely embedded in the fluid channel. This design allows the fluid to pass through the valve with almost no obstruction, effectively reducing the resistance of fluid flow. This structure helps to save energy and reduce operating costs.

Seat and Sealing: It uses a shaped sealing ring and a floating seat structure to achieve bidirectional sealing. The opening and closing torque of this structure is smaller than that of ordinary valves, making operation more convenient. The seat is usually inlaid with or clad with stainless steel or cobalt-chromium-tungsten alloy to enhance wear resistance and sealing performance.

Fluid Channel: When fully open, the valve has a smooth flow path with minimal flow resistance, reducing pressure loss and suitable for applications requiring high flow rates. Additionally, the flow path design facilitates cleaning with devices such as pigging, maintaining pipeline patency.

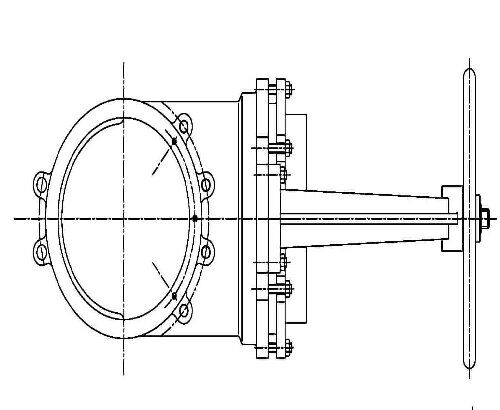

Slat Design: The slat of a knife gate valve is blade-shaped, effectively cutting off fluid flow. The blade-shaped design makes it particularly suitable for handling solid particles or viscous fluids in high-pressure and small-diameter pipelines.

Sealing Surface: The slat, made of stainless steel, prevents seal leakage caused by corrosion. The sealing surface, which has been finely ground and polished, provides excellent sealing effects. The bottom of the knife gate valve is designed with a blade edge that can cut soft materials such as fibers, pulp, and wood pulp while maintaining good opening and closing effects.

Structural Reinforcement: The valve body is designed with reinforcement ribs, enhancing the strength and durability of the valve body. Both the valve body and the stuffing box are precision cast, ensuring the overall strength of the valve. The sealing ring is made of PTFE-enhanced rubber material, which has excellent corrosion resistance and wear resistance.

When choosing between a flat gate valve and a knife gate valve, understanding their respective advantages and disadvantages can help make more demand-oriented decisions. Here is a specific analysis of the advantages and disadvantages of these two types of valves.

Bidirectional Sealing: The valve has bidirectional sealing capabilities, ensuring reliable sealing effects.

Low Flow Resistance: The smooth flow path and low flow resistance coefficient make it suitable for high-flow applications.

Easy Operation: The small opening and closing torque makes operation easy, reducing maintenance difficulty.

Easy Maintenance: The sealing surface can automatically remove debris from the slat, extending the service life.

Not Suitable for High Pressure: For high-pressure applications, the sealing performance and pressure resistance of flat gate valves may not be as good as knife gate valves.

Limited Solid Particle Handling Ability: When dealing with fluids with a lot of solid particles, its performance may not be as good as knife gate valves.

High-Pressure Adaptability: Knife gate valves perform well in high-pressure environments with excellent sealing performance.

Cutting Function: The blade-shaped slat can effectively cut off the fluid, suitable for handling fluids containing solid particles or viscous fluids.

Strong Corrosion Resistance: Stainless steel material and PTFE sealing rings make it have excellent corrosion resistance.

Compact Design: The compact valve body design occupies less space, suitable for installation environments with limited space.

High Flow Resistance: For high-flow applications, the fluid resistance of knife gate valves may be higher.

Complex Maintenance: Under high pressure, maintenance and operation are relatively complex, requiring regular inspection and maintenance.

Flat gate valves and knife gate valves each have different applicable scenarios in industrial applications. Understanding the differences in their application scenarios helps to make the best choices in practical applications, ensuring the efficient and safe operation of the system.

Applicable Range: Flat gate valves are widely used in medium and low-pressure, large-diameter pipeline systems. This design can meet the needs of large flow rates and reduce the resistance of fluids passing through the valve, thus performing excellently in the industrial field.

Application Fields: Flat gate valves are commonly found in pipeline systems in industries such as chemical engineering, metallurgy, and power. They are also used in transportation pipelines and vent systems for natural gas, oil, environmental protection, urban pipelines, and gas pipeline systems, as well as in gas storage devices.

Applicable Range: Knife gate valves are suitable for high-pressure, small-diameter pipeline systems. The knife design allows them to effectively control the flow and pressure in high-pressure systems, especially suitable for scenarios requiring precise regulation.

Application Fields: Knife gate valves are widely used in high-pressure pipeline systems in the petroleum, natural gas, and chemical industries. They have a significant advantage in handling fluids containing solid particles, such as in petroleum extraction, natural gas transportation, and chemical processing.

Flat gate valves and knife gate valves each have their unique advantages and application scenarios. Due to their low flow resistance and easy operation, flat gate valves are particularly suitable for medium and low-pressure, large-diameter pipeline systems, while knife gate valves, with their excellent high-pressure adaptability and cutting ability, are suitable for high-pressure, small-diameter applications. A comprehensive understanding of these two types of gate valves can provide a more scientific basis for the design and maintenance of pipeline systems, ensuring their efficient and safe operation.