Comprehensive Guide to Selecting Between Electric and Pneumatic Ball Valves

Ball valves have the capability to integrate with either a pneumatic actuator, resulting in pneumatic ball valves, or an electric actuator, giving rise to electric ball valves, facilitating automation and remote control. The choice between automating with a pneumatic actuator or an electric one depends on the specific application, with each option offering distinct advantages. In this article, we will conduct a comparative analysis of these two alternatives.

1. Understanding Electric and Pneumatic Ball Valves

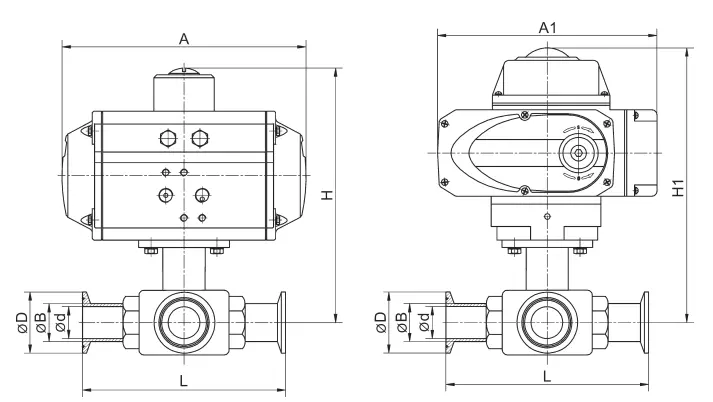

Electric Ball Valve Definition: Electric ball valves, also known as motor-driven or electrically-driven ball valves, consist of an electric actuator connected to a ball valve. This configuration utilizes electrical energy to control and regulate the valve's opening and closing actions for fluid medium flow in pipelines.

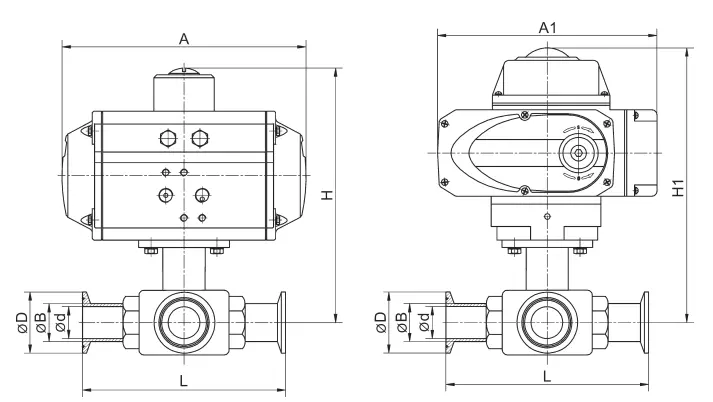

Pneumatic Ball Valve Definition: Pneumatic ball valves incorporate a ball valve with a pneumatic actuator. These valves utilize compressed air as a power source to drive the opening and closing actions, enabling automation in controlling fluid flow in pipelines. Pneumatic ball valves often include accessories like solenoid valves, air source treatment units, etc., to achieve on-site and remote centralized control.

2. Comparative Analysis of Electric and Pneumatic Ball Valves

Characteristics of Pneumatic Ball Valves

Features of Electric Ball Valves

Switching Speed Comparison: The switching time of pneumatic ball valves is typically around 6 seconds, whereas electric ball valves generally have a switching time of 15-20 seconds.

Structural and Safety Comparison: Pneumatic ball valves have a simple structure and high safety, suitable for explosive environments.

Electric ball valves offer higher precision but are more suitable for environments with lower explosion-proof requirements.

3. How to Choose Between Electric and Pneumatic Ball Valves

Working Conditions: Pneumatic valves are suitable for explosive environments, while electric valves are suitable for environments with lower requirements.

Control Requirements: If control requirements are high, consider pneumatic ball valves with intelligent positioners.

Electric ball valves are suitable for places without an air source, easy to operate, but may lack in safety and stability compared to pneumatic ball valves. Pneumatic ball valves are suitable for environments with high explosion-proof requirements, responsive in operation, but require an air source and have simple maintenance. By understanding the characteristics and advantages/disadvantages of these two types of ball valves, wise choices can be made to meet the specific requirements of different working conditions.

1. Understanding Electric and Pneumatic Ball Valves

Electric Ball Valve Definition: Electric ball valves, also known as motor-driven or electrically-driven ball valves, consist of an electric actuator connected to a ball valve. This configuration utilizes electrical energy to control and regulate the valve's opening and closing actions for fluid medium flow in pipelines.

Pneumatic Ball Valve Definition: Pneumatic ball valves incorporate a ball valve with a pneumatic actuator. These valves utilize compressed air as a power source to drive the opening and closing actions, enabling automation in controlling fluid flow in pipelines. Pneumatic ball valves often include accessories like solenoid valves, air source treatment units, etc., to achieve on-site and remote centralized control.

2. Comparative Analysis of Electric and Pneumatic Ball Valves

Characteristics of Pneumatic Ball Valves

● Actuation Force: Pneumatic valves have a larger actuation force with adjustable speed.

● Advantages: Simple structure, easy maintenance, responsive, and reliable.

● Disadvantages: Requires an air source, and the control system is relatively complex.

● Advantages: Simple structure, easy maintenance, responsive, and reliable.

● Disadvantages: Requires an air source, and the control system is relatively complex.

Features of Electric Ball Valves

● Actuation Force: Electric valves use electrical power, and their actuation speed is relatively slower.

● Advantages: Precision, not affected by air pressure fluctuations, suitable for applications with lower control requirements.

● Disadvantages: Higher cost, relatively complex maintenance, not suitable for explosive environments.

● Advantages: Precision, not affected by air pressure fluctuations, suitable for applications with lower control requirements.

● Disadvantages: Higher cost, relatively complex maintenance, not suitable for explosive environments.

Switching Speed Comparison: The switching time of pneumatic ball valves is typically around 6 seconds, whereas electric ball valves generally have a switching time of 15-20 seconds.

Structural and Safety Comparison: Pneumatic ball valves have a simple structure and high safety, suitable for explosive environments.

Electric ball valves offer higher precision but are more suitable for environments with lower explosion-proof requirements.

3. How to Choose Between Electric and Pneumatic Ball Valves

Working Conditions: Pneumatic valves are suitable for explosive environments, while electric valves are suitable for environments with lower requirements.

Control Requirements: If control requirements are high, consider pneumatic ball valves with intelligent positioners.

Electric ball valves are suitable for places without an air source, easy to operate, but may lack in safety and stability compared to pneumatic ball valves. Pneumatic ball valves are suitable for environments with high explosion-proof requirements, responsive in operation, but require an air source and have simple maintenance. By understanding the characteristics and advantages/disadvantages of these two types of ball valves, wise choices can be made to meet the specific requirements of different working conditions.