Butterfly valves, based on their sealing states, are categorized into soft seal and hard seal variants. The commonly used soft seal includes fluorine-lined butterfly valves, while the hard seal category encompasses metal hard-seal disc valves. Hard seal butterfly valves refer to valves where both sides of the sealing pair consist of metal or other relatively hard materials. While hard-seal butterfly valves may exhibit inferior sealing performance, they boast high-temperature resistance, wear resistance, and excellent mechanical properties. Examples include steel-to-steel, steel-to-copper, steel-to-graphite, and steel-to-alloy steel configurations. The following sections briefly introduce the product advantages and maintenance considerations for hard-seal butterfly valves.

Advantages of Hard Seal Butterfly Valves:

-

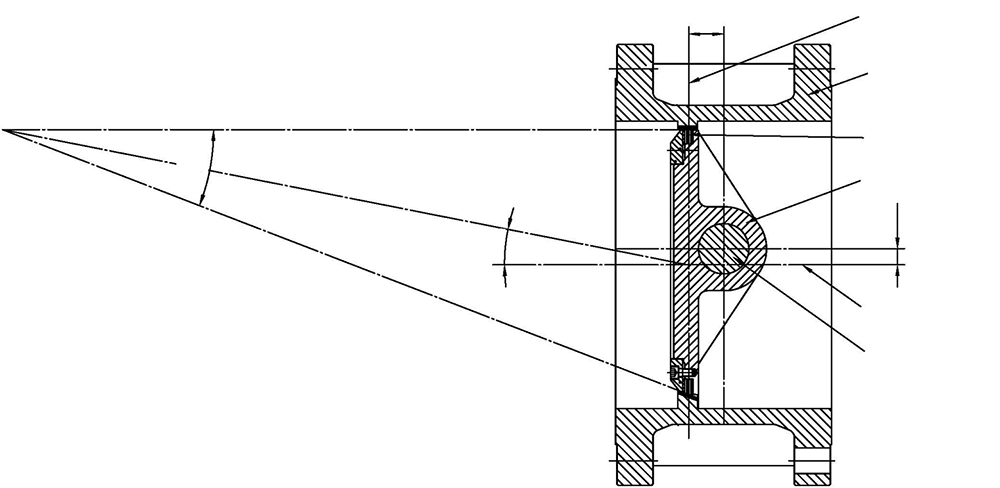

Hard seal butterfly valves employ a triple eccentric sealing structure, providing increasingly tight sealing over time with minimal damage to the high-pressure gate and butterfly disc.

-

The sealing ring utilizes stainless steel, combining the advantages of metal hard sealing and resilient sealing. It excels in maintaining good sealing characteristics, corrosion resistance, and robust durability in both low and high-temperature environments.

-

The butterfly disc's sealing surface features cobalt-based hard alloy coating, ensuring wear resistance and prolonged durability.

-

Large-sized butterfly discs adopt a frame structure, offering high strength, a large flow area, and low fluid density.

-

Hard seal butterfly valves provide dual-sealing functionality, unaffected by medium flow direction during installation and immune to spatial coordinate constraints. They can be installed in any orientation.

-

The drive mechanism can be assembled in various positions (rotating 90° or 180°), ensuring user convenience.

Hard seal butterfly valves refer to valves where the closure component (piston or butterfly disc) is a circular plate that rotates tightly around the valve shaft to achieve opening and closing functions in pipelines. The closure component is a circular disc-shaped butterfly plate that rotates around its central axis within the valve body, achieving the purpose of opening, closing, or regulating the flow.

Maintenance Guidelines for Hard Seal Butterfly Valves:

-

Regularly clean hard seal butterfly valves during use. Lubricate the transmission threads on time, and promptly stop using them if faults are detected. Investigate the cause and eliminate common issues.

-

Ensure uniform tightening of the nuts on the filler rotating cap, preventing misalignment to avoid damaging the valve seat and hindering its proper functioning, possibly leading to leaks.

-

During installation, immediately fit gate valves onto pipeline routes in accordance with interface methods. While generally installable in any pipeline position, it is crucial to facilitate maintenance. Pay attention to the media flow direction of the globe valve during installation; it should be from below the globe valve for vertical assembly.

-

Hard seal butterfly valves should only be used for opening or full closing, not for flow regulation. The stop valve and upper threaded stop valve have a reverse-sealing structure. Tightening the handwheel to the upper position can prevent substances from leaking from the filler.

-

When operating hard seal butterfly valves, use the handwheel for opening and closing, avoiding reliance on financial levers or other tools to prevent damage to valve components. Turn the handwheel clockwise to close and counterclockwise to open.

-

Before construction, carefully check the working pressure and pipe diameter specified on the valve label. Clear any defects caused during transportation and clean the stains on the valve components.

-

For long-term stored gate valves, conduct regular maintenance. Keep the exposed production processing surface clean, remove stains, and store the valve with both ends blocked in the open position. For pneumatic disc valves, block both sides of the channel and keep it in the closed state. Store them neatly in a well-ventilated, cool, and dry place, avoiding stacking or outdoor storage.

In conclusion, hard seal butterfly valves offer unique advantages in terms of sealing structure and material composition. Following proper maintenance guidelines ensures prolonged and reliable performance in diverse applications.