Exploring the Distinctive Features of Double and Triple Eccentric Butterfly Valves

Butterfly valves play a pivotal role in fluid control systems, and among them, the double and triple eccentric butterfly valves stand out for their unique characteristics. This article delves into the structural variances, operational aspects, and applications of these two types of valves.

Double Eccentric Butterfly Valve

Triple Eccentric Butterfly Valve

Comparative Analysis of Double and Triple Eccentric Butterfly Valves

Understanding the distinct features of double and triple eccentric butterfly valves is crucial for selecting the right valve for specific applications. While the double eccentric excels in simplicity and flexibility, the triple eccentric is designed for robust performance in demanding conditions. Each valve type serves unique purposes, catering to diverse needs in fluid control systems.

Double Eccentric Butterfly Valve

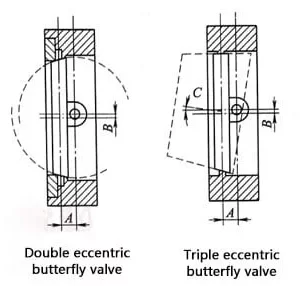

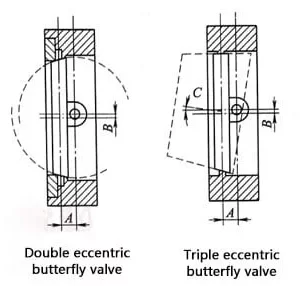

● Definition and Structure: The double eccentric butterfly valve features a two-offset disk configuration. Unlike its single eccentric counterpart, the stem is positioned behind the disk. The second offset stem is strategically placed off-center from the middle of the disk, allowing for minimal torque during operation.

● Temperature and Pressure Range: This valve can be utilized in applications with temperatures reaching up to 325°C and pressures as high as 50 bars. The seat is composed of soft material, offering flexibility.

● Advantages and Disadvantages: The double eccentric butterfly valve's unique design facilitates easy opening and robust sealing strength. However, its line seal nature makes it suitable for applications with lower closing position requirements and lower pressure-bearing capacity.

● Temperature and Pressure Range: This valve can be utilized in applications with temperatures reaching up to 325°C and pressures as high as 50 bars. The seat is composed of soft material, offering flexibility.

● Advantages and Disadvantages: The double eccentric butterfly valve's unique design facilitates easy opening and robust sealing strength. However, its line seal nature makes it suitable for applications with lower closing position requirements and lower pressure-bearing capacity.

Triple Eccentric Butterfly Valve

● Definition and Structure: In contrast, the triple eccentric butterfly valve boasts three different offset valves. Two offsets are centered, while the third is positioned on the seat surface, shaping the disk and seat in a cone form.

● Temperature and Pressure Range: This valve is engineered for demanding, long-term applications with temperatures up to 932°F (500°C) and a remarkable pressure tolerance of up to 725 psi (50 bars). The seat is constructed of hard metal for durability.

● Operational Distinction: Unlike traditional butterfly valves, the triple eccentric type operates similarly to a globe valve. The disk's cone-like movement, combined with the angled positioning, ensures a strong seal and eliminates drag during contact between the seat and the disk.

● Temperature and Pressure Range: This valve is engineered for demanding, long-term applications with temperatures up to 932°F (500°C) and a remarkable pressure tolerance of up to 725 psi (50 bars). The seat is constructed of hard metal for durability.

● Operational Distinction: Unlike traditional butterfly valves, the triple eccentric type operates similarly to a globe valve. The disk's cone-like movement, combined with the angled positioning, ensures a strong seal and eliminates drag during contact between the seat and the disk.

Comparative Analysis of Double and Triple Eccentric Butterfly Valves

1. Structural Characteristics

Double Eccentric: Stem axis deviates from both the center of the butterfly plate and the center of the body.

Triple Eccentric: Stem axis and the cone-shaped axis of the sealing surface deviate from the center of the disc and the center of the body.

2. Advantages and Applications

Double Eccentric: Quick detachment of the disk from the seat enhances valve life. Suited for applications with lower closing position requirements and pressure-bearing capacity.

Triple Eccentric: Realizes torque seal, solving zero leakage issues. Ideal for high-temperature and high-pressure scenarios due to proportional contact surface pressure.

Double Eccentric: Stem axis deviates from both the center of the butterfly plate and the center of the body.

Triple Eccentric: Stem axis and the cone-shaped axis of the sealing surface deviate from the center of the disc and the center of the body.

2. Advantages and Applications

Double Eccentric: Quick detachment of the disk from the seat enhances valve life. Suited for applications with lower closing position requirements and pressure-bearing capacity.

Triple Eccentric: Realizes torque seal, solving zero leakage issues. Ideal for high-temperature and high-pressure scenarios due to proportional contact surface pressure.

Understanding the distinct features of double and triple eccentric butterfly valves is crucial for selecting the right valve for specific applications. While the double eccentric excels in simplicity and flexibility, the triple eccentric is designed for robust performance in demanding conditions. Each valve type serves unique purposes, catering to diverse needs in fluid control systems.