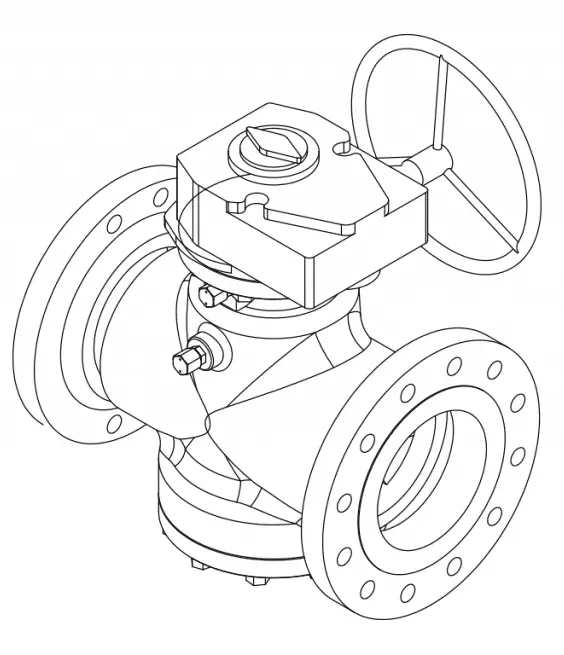

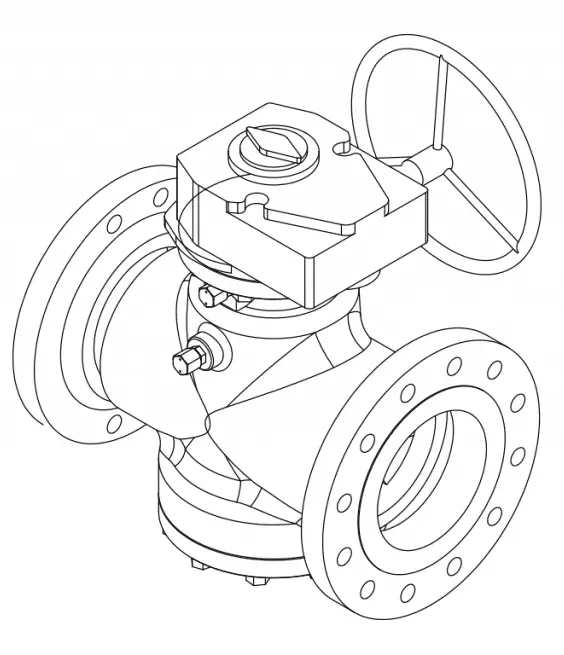

Explore the Features and Benefits of Pressure Balanced Plug Valve

The pressure balanced plug valve is a symbol of engineering excellence, distinguished by its sophisticated design, reliable sealing, and exceptional performance. Unlike traditional plug valves, its advanced pressure balancing mechanism provides superior sealing and torque management, making the plug valve a preferred choice across diverse applications. In this overview, we'll explore the pressure balanced plug valve's structural features, unique advantages, and the crucial role of seal lubrication selection for optimal performance.

1. Structural Features and Benefits

The pressure balanced plug valve offers a range of structural features and benefits that make it an exceptional choice for fluid control applications. Let's explore some key features and their corresponding benefits:

2. Distinctive Advantages of Pressure Balanced Plug Valve

The pressure balanced plug valve stands out due to its distinctive advantages, making it a preferred choice in fluid control applications. Let's explore the unique benefits that set the pressure balanced plug valve apart:

3. Significance of Seal Lubricant Selection

While oil-lubricated hard-sealed plug valves offer moderate torque reduction during opening and closing, they pose the risk of medium contamination. Hence, meticulous selection of suitable seal lubricants is imperative in actual operating conditions to ensure sustained stable valve performance and prevent medium contamination.

In summary, the pressure balanced plug valve, with its superior structural design and performance attributes, emerges as an indispensable asset in the engineering realm. Continual refinement in design and material selection will see the pressure balanced plug valve extend its pivotal role across an expanded array of applications, delivering unwavering reliability for engineering endeavors.

1. Structural Features and Benefits

The pressure balanced plug valve offers a range of structural features and benefits that make it an exceptional choice for fluid control applications. Let's explore some key features and their corresponding benefits:

- Rational Design and Reliable Sealing: The pressure balanced plug valve not only boasts an appealing exterior but also features a rational structure and dependable sealing mechanism. Its pressure balancing design facilitates smooth valve operations while enhancing sealing efficacy.

- Oil Groove Lubrication Design: Introducing oil grooves between the valve body and sealing surface enables the injection of sealing grease into the valve seat through a designated oil nozzle. This augmentation further bolsters sealing performance, ensuring sustained stable valve operation.

- Flexible Configuration: Tailoring component materials and flange dimensions to actual operating conditions or user preferences allows for flexible configuration, meeting a spectrum of engineering requirements. This enhances product adaptability and versatility.

2. Distinctive Advantages of Pressure Balanced Plug Valve

The pressure balanced plug valve stands out due to its distinctive advantages, making it a preferred choice in fluid control applications. Let's explore the unique benefits that set the pressure balanced plug valve apart:

A. Inverted Installation with Pressure Balancing Structure: Employing an inverted installation method with an upper check valve, the valve capitalizes on the differential cross-sectional area of the plug. During valve closure, high-pressure sealing oil prompts upward lifting force on the plug, significantly enhancing sealing effectiveness.

B. Torque Reduction and Seal Preservation: Upon valve opening, the high-pressure sealing oil in the upper chamber exerts downward pressure on the plug, creating a minute gap between the plug and valve body sealing surface. This minimizes rotational torque requirements and safeguards sealing components, thereby prolonging their service life.

C. Adaptation to High-Temperature Environments: In high-temperature conditions, the plug's thermal expansion is accommodated through vertical movement, preventing sealing component jamming and ensuring uninterrupted valve operation.

B. Torque Reduction and Seal Preservation: Upon valve opening, the high-pressure sealing oil in the upper chamber exerts downward pressure on the plug, creating a minute gap between the plug and valve body sealing surface. This minimizes rotational torque requirements and safeguards sealing components, thereby prolonging their service life.

C. Adaptation to High-Temperature Environments: In high-temperature conditions, the plug's thermal expansion is accommodated through vertical movement, preventing sealing component jamming and ensuring uninterrupted valve operation.

3. Significance of Seal Lubricant Selection

While oil-lubricated hard-sealed plug valves offer moderate torque reduction during opening and closing, they pose the risk of medium contamination. Hence, meticulous selection of suitable seal lubricants is imperative in actual operating conditions to ensure sustained stable valve performance and prevent medium contamination.

In summary, the pressure balanced plug valve, with its superior structural design and performance attributes, emerges as an indispensable asset in the engineering realm. Continual refinement in design and material selection will see the pressure balanced plug valve extend its pivotal role across an expanded array of applications, delivering unwavering reliability for engineering endeavors.