Steam Jacketed Globe Valves: Basics and Applications

In industrial pipelines, steam jacketed globe valves are vital for controlling media flow, ensuring system stability and safety. Widely utilized in sectors like petroleum, chemical, metallurgy, and pharmaceuticals, these globe valves are valued for their straightforward design and dependable efficiency. They excel in various conditions, especially when handling high-viscosity media prone to solidifying at standard temperatures. This article explores the design features, applications, advantages, disadvantages, and future trends of steam jacketed globe valves.

1. Design Features

Steam jacketed globe valves are designed with multiple considerations to meet the diverse requirements of pipeline control in different industrial sectors:

2. Advantages and Disadvantages

Steam jacketed globe valves, like any engineering solution, have their own set of advantages and disadvantages:

3. Applications

Steam jacketed globe valves have extensive applications across various industries, primarily manifested in the following areas:

Steam jacketed globe valves are vital components in industrial pipeline systems, playing a crucial role in ensuring stable operation and safety. While their design and application meet industrial needs, they also face challenges. With technological advancements and evolving demands, steam jacketed globe valves will continue to develop, providing more reliable and efficient solutions for industrial pipeline control.

1. Design Features

Steam jacketed globe valves are designed with multiple considerations to meet the diverse requirements of pipeline control in different industrial sectors:

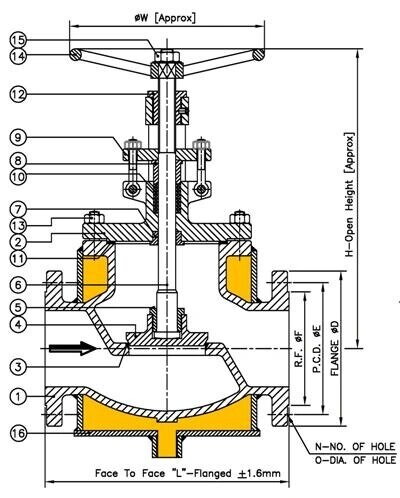

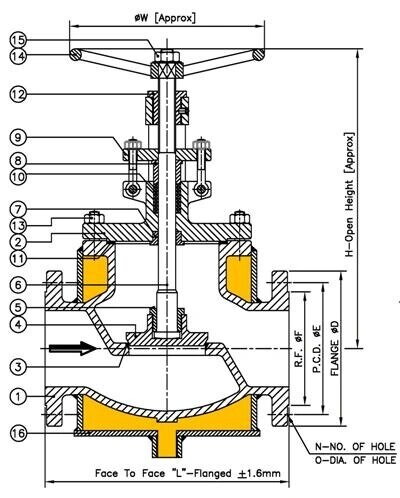

- Closure Mechanism Design: Employing tapered valve plugs with sealing surfaces that can be flat or conical ensures complete sealing when the valve is closed, effectively preventing media leakage.

- Valve Stem Movement Forms: There are two forms—rising and lowering stem and rising and lowering rotating stem. The design of the rising and lowering stem separates the stem's movement from the operation of the handwheel, facilitating the control of the valve by operators.

- Characteristics: Suitable for full open and full close positions, they are not suitable for adjustment and throttling operations, ensuring the stability and reliability of the valve.

- Material Selection: Valve materials typically consist of corrosion-resistant and high-temperature-resistant alloy materials to ensure long-term stable operation under harsh conditions.

2. Advantages and Disadvantages

Steam jacketed globe valves, like any engineering solution, have their own set of advantages and disadvantages:

Major Advantages

- Excellent Sealing: Using tapered valve plugs with minimal friction between sealing surfaces ensures a long service life and effectively prevents media leakage.

- Convenient Operation: Simple structure and fast opening and closing speed make steam jacketed globe valves suitable for situations requiring rapid response.

- High Reliability: Through rigorous design and testing, steam jacketed globe valves demonstrate stable performance and low failure rates over long-term operation.

Some Disadvantages

- High Fluid Resistance: Due to their structural characteristics, steam jacketed globe valves generate significant fluid resistance during opening and closing, increasing the difficulty of operation.

- Media Limitations: They are not suitable for media with particles, high viscosity, or tendencies to coking, limiting their application range in certain scenarios.

- Poor Adjustment Performance: Compared to other types of valves, steam jacketed globe valves have poorer adjustment performance and are not suitable for situations requiring precise flow control.

3. Applications

Steam jacketed globe valves have extensive applications across various industries, primarily manifested in the following areas:

- Transportation of High-Viscosity Media: For high-viscosity media prone to solidification at normal temperatures, such as petroleum and asphalt, steam jacketed globe valves effectively control media flow, ensuring the normal operation of systems.

- Chemical and Fertilizer Industries: Due to the unique properties of media in these industries, it is essential to prevent crystallization issues from affecting system operation. Hence, steam jacketed globe valves are widely used. Injecting steam into the jacket prevents media crystallization, ensuring continuous system operation.

- Pharmaceutical Industry: In pharmaceutical production, where stringent control over media is necessary, steam jacketed globe valves ensure the purity and stability of the media, contributing to maintaining the quality of pharmaceutical products.

Steam jacketed globe valves are vital components in industrial pipeline systems, playing a crucial role in ensuring stable operation and safety. While their design and application meet industrial needs, they also face challenges. With technological advancements and evolving demands, steam jacketed globe valves will continue to develop, providing more reliable and efficient solutions for industrial pipeline control.