Unveiling the Power of Bidirectional Metal-to-Metal Butterfly Valves

The bidirectional metal-to-metal butterfly valves stand as a cornerstone in fluid control systems, presenting unmatched advantages across diverse industries. Renowned for its superior sealing, compact design, and stable operation, alongside versatile actuation options, the butterfly valve fulfills essential roles including flow control, backflow prevention, and pressure regulation. In this article, we will delve deeper into its multifaceted capabilities and widespread applications.

About Bidirectional Metal-to-metal Butterfly Valve

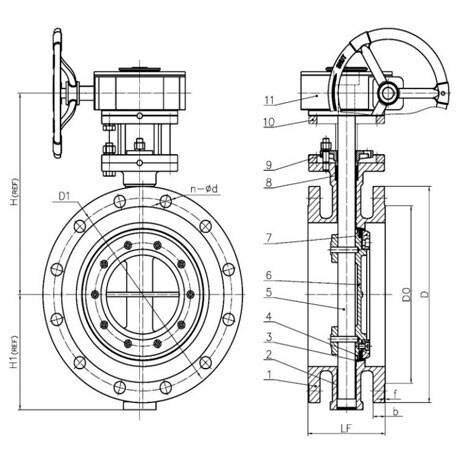

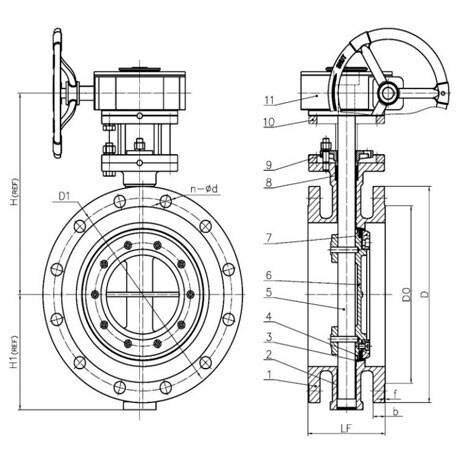

The bidirectional metal-to-metal butterfly valve is a common fluid control device composed of a valve body, valve disc, valve stem, sealing ring, and other components. The valve disc is typically circular or elliptical, with the valve stem passing through it to regulate the opening and closing of the valve through rotation. The sealing ring, located at the edge of the valve disc, ensures the valve's sealing performance. It is distinguished by the inclusion of two butterfly-shaped valves internally, allowing for bidirectional flow control and adjustment. Widely utilized in industries such as chemical, pharmaceutical, food, and power, it facilitates flow control and regulation within pipelines.

The Major Advantages

When it comes to fluid control, bidirectional metal-to-metal butterfly valves offer unparalleled advantages. Their innovative design and robust construction make them indispensable across various industries. Here are some key benefits:

Its Main Functions

Bidirectional metal-to-metal butterfly valves are engineered to fulfill critical functions in fluid control systems, offering versatility and reliability. Here are the primary functions they serve:

Versatile Applications

The bidirectional metal-to-metal butterfly valve finds applications across various industries due to its versatility and effectiveness in fluid control. Some common applications include:

As a crucial tool in modern pipeline control, the bidirectional metal-to-metal butterfly valve's superior performance and widespread application have gained recognition across various industries. In the future, with continuous technological advancements and expanding areas of use, it is poised to play an even more significant role in pipeline control.

About Bidirectional Metal-to-metal Butterfly Valve

The bidirectional metal-to-metal butterfly valve is a common fluid control device composed of a valve body, valve disc, valve stem, sealing ring, and other components. The valve disc is typically circular or elliptical, with the valve stem passing through it to regulate the opening and closing of the valve through rotation. The sealing ring, located at the edge of the valve disc, ensures the valve's sealing performance. It is distinguished by the inclusion of two butterfly-shaped valves internally, allowing for bidirectional flow control and adjustment. Widely utilized in industries such as chemical, pharmaceutical, food, and power, it facilitates flow control and regulation within pipelines.

The Major Advantages

When it comes to fluid control, bidirectional metal-to-metal butterfly valves offer unparalleled advantages. Their innovative design and robust construction make them indispensable across various industries. Here are some key benefits:

- Superior Sealing: Incorporates a specialized metal-to-metal sealing structure, ensuring exceptional internal sealing performance and effectively preventing leakage issues.

- Compact Design: The valve features a highly compact structure, enabling efficient control operations within confined spaces without compromising performance.

- Stable Operation: Utilizes electric or pneumatic systems for precise control over valve opening and closing, ensuring stability in pipeline regulation and control.

- Versatile Operation: Offers flexibility in operation, with options for manual, pneumatic, and electric actuation, catering to diverse industrial needs and preferences.

- Minimal Pressure Loss: The valve design minimizes the gap between the valve disc and the fluid during operation, resulting in minimal pressure loss and improved energy efficiency.

- Space-Saving: Requires only a 90-degree rotation for switching, occupying minimal space in pipeline systems, thereby optimizing infrastructure layout and installation.

- Robust Corrosion Resistance: Constructed from materials such as stainless steel and aluminum alloy, exhibiting robust resistance to corrosion from various aggressive media, ensuring longevity and reliability in harsh operating environments.

Bidirectional metal-to-metal butterfly valves are engineered to fulfill critical functions in fluid control systems, offering versatility and reliability. Here are the primary functions they serve:

1. Flow Control: The bidirectional metal-to-metal butterfly valve can regulate the size of fluid flow by rotating the valve disc, adjusting the flow of liquid or gas in industrial production to meet process requirements.

2. Backflow Prevention: The inclusion of two valves prevents fluid backflow, ensuring smooth and stable production.

3. Pressure Regulation: Commonly employed in pipeline systems to control fluid pressure, preventing pipe bursts or unstable pressure situations.

4. Energy Conservation: With minimal pressure loss during flow control and flexible operation, it effectively conserves energy.

2. Backflow Prevention: The inclusion of two valves prevents fluid backflow, ensuring smooth and stable production.

3. Pressure Regulation: Commonly employed in pipeline systems to control fluid pressure, preventing pipe bursts or unstable pressure situations.

4. Energy Conservation: With minimal pressure loss during flow control and flexible operation, it effectively conserves energy.

Versatile Applications

The bidirectional metal-to-metal butterfly valve finds applications across various industries due to its versatility and effectiveness in fluid control. Some common applications include:

- Petrochemical Industry: Widely used in the petrochemical industry for oil and gas transportation, oil production, storage, and other processes, ensuring efficient pipeline transport and control.

- Water Supply: Extensively applied in the water supply industry to control the flow and pressure of tap water, reducing water wastage and improving water supply quality.

- Wastewater Treatment: In the wastewater treatment sector, it controls the flow of incoming and outgoing wastewater, preventing water quality deterioration and ensuring environmental protection.

As a crucial tool in modern pipeline control, the bidirectional metal-to-metal butterfly valve's superior performance and widespread application have gained recognition across various industries. In the future, with continuous technological advancements and expanding areas of use, it is poised to play an even more significant role in pipeline control.