Check valves play a crucial role in governing unidirectional fluid flow and thwarting backflow. Among these, lift check valves and swing check valves stand out as key contenders. This article delves deep into their intricate structures, application versatility, performance nuances, and classification intricacies, providing an exhaustive comparison of the two check valves to facilitate well-informed decision-making.

The structural variances between lift check valves and swing check valves primarily hinge on their distinct operational mechanisms. Here's a detailed comparison.

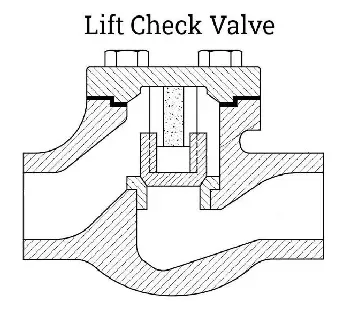

Lift Check Valve: In appearance reminiscent of globe valves, lift check valves set themselves apart by eliminating the need for a valve stem to actuate the disc. The disc enjoys unimpeded vertical movement, akin to the operational principle of a globe valve.

Both types of valves cater to a wide array of applications, albeit with differing design considerations:

Swing Check Valve: Exhibiting remarkable versatility, swing check valves seamlessly integrate into both horizontal and vertical pipelines, provided that fluid flow occurs from bottom to top.

Each valve type demonstrates distinct performance characteristics:

Lift Check Valve: Defined by a narrower passage, lift check valves typically encounter higher pressure drops and flow resistance. Nonetheless, their sealing performance remains exceptional.

Swing Check Valve: With fewer flow constraints, swing check valves accommodate various media types. However, caution is warranted when dealing with media containing solid particles or exhibiting high viscosity.

Both lift check valves and swing check valves undergo classification based on specific criteria:

Lift Check Valve: Categorized into vertical and horizontal types, simplifying the selection process based on particular installation prerequisites.

Swing Check Valve: Further nuanced classification based on valve diameter encompasses single-disc, double-disc, and multiple-disc variants, catering to a spectrum of flow rate demands.

Lift check valves and swing check valves, each possessing unique attributes, carve out their niches in distinct applications. The choice between the two hinges on factors such as pipeline layout, fluid characteristics, and desired flow parameters. There exists no universally superior option; instead, the selection should align closely with the system's specific requirements to ensure optimal and dependable pipeline operation.