Axial Flow Check Valves: Unmatched Reliability and Low Maintenance Costs

Step into the future of fluid control with axial flow check valves – a blend of reliability and efficiency. Streamlined and efficient, these check valves minimize maintenance costs and excel in various applications. From oil and gas systems to fluid transportation, the axial flow check valves offer low flow resistance, a large flow coefficient, and compact dimensions. In the following parts, the mystery of this check valve will be unveiled through various aspects.

1. About Axial Flow Check Valve

The evolution of axial flow check valves finds its roots in the pursuit of an ideal design, aiming to achieve unparalleled reliability and minimal maintenance costs across diverse applications. Over the years, axial flow check valves have demonstrated outstanding performance in terms of reliability and adaptability, proving their efficacy in challenging environments.

2. Working Principle: Precision in Motion

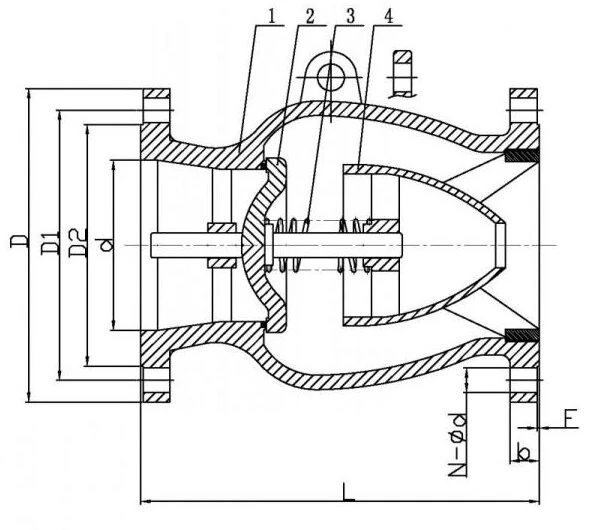

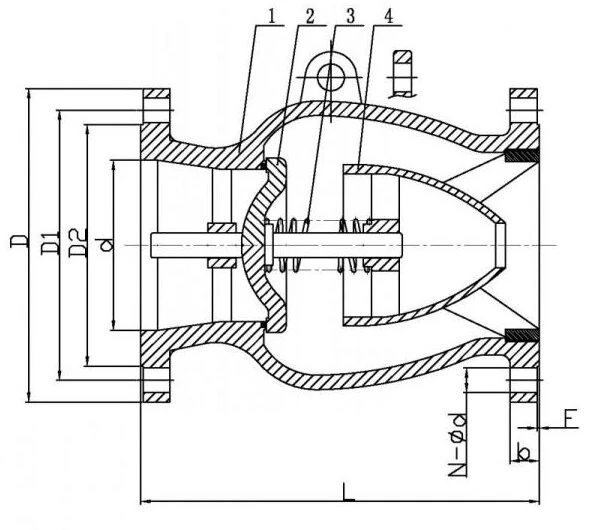

The working principle of an axial flow check valve centers around its precision engineering and seamless functionality. Utilizing an axial flow shuttle structure and buffering shock-absorbing springs on the valve disc, this valve operates with remarkable accuracy.

3. Design Characteristics: A Blend of Form and Function

4. Key Features of Axial Flow Check Valves

5. Advantages of the Unique Axial Flow Shuttle Structure

The lightweight, fast-closing valve disc in axial flow check valves prevents premature wear, noise, and vibration. With a small mass and low inertia, it enables quick closure in a short stroke, minimizing impact force and preserving the valve seat sealing surface integrity, preventing leaks. Axial flow check valves offer a reliable and cost-effective solution across diverse industrial applications, marking a substantial advancement in valve technology.

1. About Axial Flow Check Valve

The evolution of axial flow check valves finds its roots in the pursuit of an ideal design, aiming to achieve unparalleled reliability and minimal maintenance costs across diverse applications. Over the years, axial flow check valves have demonstrated outstanding performance in terms of reliability and adaptability, proving their efficacy in challenging environments.

2. Working Principle: Precision in Motion

The working principle of an axial flow check valve centers around its precision engineering and seamless functionality. Utilizing an axial flow shuttle structure and buffering shock-absorbing springs on the valve disc, this valve operates with remarkable accuracy.

Axial Flow Shuttle Structure: Axial flow check valves employ a precise axial flow shuttle structure with shock-absorbing springs on the valve disc for reliable operation.

Forward Flow Dynamics: In forward flow, the valve disc gracefully opens, facilitating the medium's smooth traversal through the axial flow channel.

Buffering Effect during Closure: During closure, the integrated spring buffers, preventing impact vibrations between the valve disc and body, a common challenge in regular check valves.

Swift Response to Backflow: Swift and precise, the valve disc promptly closes upon medium backflow, forming a tight seal against the valve seat to prevent reverse flow.

Innovative Seat Structure: The combined hard-sealed and soft-sealed seat structure not only prevents media backflow but also minimizes impact noise during valve disc and seat contact.

Forward Flow Dynamics: In forward flow, the valve disc gracefully opens, facilitating the medium's smooth traversal through the axial flow channel.

Buffering Effect during Closure: During closure, the integrated spring buffers, preventing impact vibrations between the valve disc and body, a common challenge in regular check valves.

Swift Response to Backflow: Swift and precise, the valve disc promptly closes upon medium backflow, forming a tight seal against the valve seat to prevent reverse flow.

Innovative Seat Structure: The combined hard-sealed and soft-sealed seat structure not only prevents media backflow but also minimizes impact noise during valve disc and seat contact.

3. Design Characteristics: A Blend of Form and Function

- Combined Mechanisms: The design incorporates shock-absorbing springs and a hard-sealed with soft-sealed seat structure, enhancing reliability.

- Compact Exterior: Axial flow check valves feature a compact and aesthetically pleasing external structure, ensuring both functionality and visual appeal.

- Axial Flow Shuttle Structure Advantages: The unique axial flow shuttle structure offers low flow resistance and a large flow coefficient, positioning these valves as superior choices for fluid control applications.

4. Key Features of Axial Flow Check Valves

Streamlined Design: Axial flow check valves feature a streamlined design for fluid flow surfaces, minimizing turbulence with well-crafted flow channels, guide hoods, and valve discs.

Shock-Absorbing Springs: Equipped with shock-absorbing springs, these valves go beyond the basics, enhancing performance and reliability.

Innovative Seat Structure: The combination of a hard-sealed and soft-sealed seat structure provides soundproofing, shock absorption, and facilitates on-site maintenance.

Shock-Absorbing Springs: Equipped with shock-absorbing springs, these valves go beyond the basics, enhancing performance and reliability.

Innovative Seat Structure: The combination of a hard-sealed and soft-sealed seat structure provides soundproofing, shock absorption, and facilitates on-site maintenance.

5. Advantages of the Unique Axial Flow Shuttle Structure

Low Flow Resistance: The axial flow shuttle structure ensures low flow resistance, contributing to a smooth passage for fluids.

Large Flow Coefficient: This structure also offers a large flow coefficient, enabling efficient handling of substantial fluid volumes.

Compact Dimensions: With compact dimensions, axial flow check valves are preferred in oil and gas systems, especially at oil pump outlets.

Large Flow Coefficient: This structure also offers a large flow coefficient, enabling efficient handling of substantial fluid volumes.

Compact Dimensions: With compact dimensions, axial flow check valves are preferred in oil and gas systems, especially at oil pump outlets.

The lightweight, fast-closing valve disc in axial flow check valves prevents premature wear, noise, and vibration. With a small mass and low inertia, it enables quick closure in a short stroke, minimizing impact force and preserving the valve seat sealing surface integrity, preventing leaks. Axial flow check valves offer a reliable and cost-effective solution across diverse industrial applications, marking a substantial advancement in valve technology.