Unveiling the Efficiency of Stainless Steel Globe Valves

Entering the world of stainless steel globe valves, where efficiency meets innovation. Explore their streamlined design, wear-resistant sealing, and compact structure. Uncover the dual-seal efficiency and zero fluid loss that define their pros, while navigating through limitations. Join us in recognizing the pivotal role these globe valves play in modern industrial applications, from energy production to chemical processes.

The Distinctive Characteristics of Stainless Steel Globe Valves

Stainless steel globe valves stand out in the realm of fluid control, offering unique features that contribute to their efficiency and reliability. Let's delve into the distinctive characteristics that make these valves an essential component in various industrial applications.

Pros and Cons of Stainless Steel Globe Valves

Stainless steel globe valves are integral components in fluid control systems, offering a range of advantages and limitations. Understanding their pros and cons is essential for informed decision-making in industrial applications.

Stainless steel globe valves, efficient and reliable, play a crucial role in modern industries. Their precision in flow control, adaptability, and durability make them key players. Despite operational challenges and considerations, these valves remain a cornerstone for fluid dynamics in industrial processes.

The Distinctive Characteristics of Stainless Steel Globe Valves

Stainless steel globe valves stand out in the realm of fluid control, offering unique features that contribute to their efficiency and reliability. Let's delve into the distinctive characteristics that make these valves an essential component in various industrial applications.

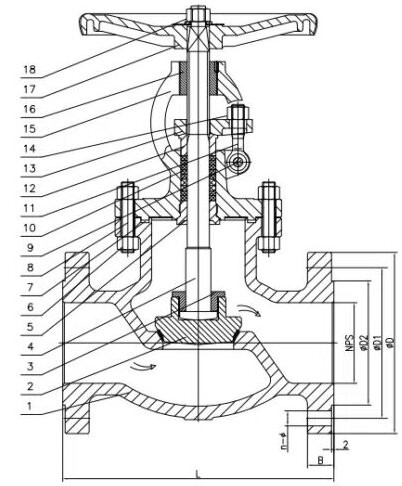

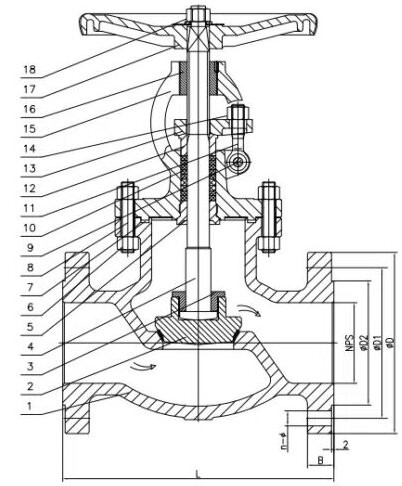

Simplicity for Efficiency: Globe valves boast a streamlined structure, simplifying both manufacturing and maintenance processes when compared to their gate valve counterparts.

Wear-resistant Sealing Excellence: The sealing surface, resilient to wear and damage, ensures outstanding performance. Minimal sliding between the valve disc and body during operation mitigates wear and tear concerns.

Compact Design, Minimal Stroke: With a smaller stroke during valve disc movement, globe valves achieve a relatively compact height, although the structural length slightly exceeds that of gate valves.

Substantial Torque, Time-Intensive Operation: Operating with a robust torque, globe valves demand more force for both opening and closing, leading to a longer operational timeframe.

Elevated Fluid Resistance: The intricate fluid passage within the valve body contributes to increased fluid resistance and higher power consumption.

Flow Direction Precision: Nominal pressures dictate the flow direction; lower pressures typically use downstream flow, while higher pressures opt for upstream flow to enhance sealing. Globe valves strictly control the medium's flow direction, prohibiting alterations during operation.

Wear-resistant Sealing Excellence: The sealing surface, resilient to wear and damage, ensures outstanding performance. Minimal sliding between the valve disc and body during operation mitigates wear and tear concerns.

Compact Design, Minimal Stroke: With a smaller stroke during valve disc movement, globe valves achieve a relatively compact height, although the structural length slightly exceeds that of gate valves.

Substantial Torque, Time-Intensive Operation: Operating with a robust torque, globe valves demand more force for both opening and closing, leading to a longer operational timeframe.

Elevated Fluid Resistance: The intricate fluid passage within the valve body contributes to increased fluid resistance and higher power consumption.

Flow Direction Precision: Nominal pressures dictate the flow direction; lower pressures typically use downstream flow, while higher pressures opt for upstream flow to enhance sealing. Globe valves strictly control the medium's flow direction, prohibiting alterations during operation.

Pros and Cons of Stainless Steel Globe Valves

Stainless steel globe valves are integral components in fluid control systems, offering a range of advantages and limitations. Understanding their pros and cons is essential for informed decision-making in industrial applications.

1. Pros of Stainless Steel Globe Valves

Precise Flow Control: Stainless steel globe valves excel in regulating fluid flow with precision, making them suitable for applications that require accurate control over the flow rate.

Versatility in Media Handling: These valves are adaptable to a diverse range of media, including corrosive and abrasive fluids, showcasing their versatility in different industrial settings.

Reliable Sealing Mechanism: The sealing mechanism, often involving wear-resistant surfaces and a dual-seal design, ensures reliable performance and minimizes the risk of leaks.

Controlled Flow Direction: Stainless steel globe valves provide precise control over the flow direction, enhancing their effectiveness in various operational scenarios.

Robust Construction for Durability: Constructed from stainless steel, these valves exhibit durability and resilience, resulting in a longer service life and reduced maintenance requirements.

Zero Fluid Loss: The design of stainless steel globe valves allows for minimal fluid loss during operation, contributing to enhanced energy efficiency and a cleaner working environment.

2. Cons of Stainless Steel Globe Valves

Operational Challenges: These valves often require substantial force for operation, leading to higher operational torque and, in turn, increased energy consumption.

Limited Adjustability: Stainless steel globe valves may have constraints in terms of adjustability, limiting their suitability for applications that require frequent adjustments.

High Fluid Resistance: The intricate fluid passages within the valve body can result in elevated fluid resistance, leading to increased power requirements for fluid flow.

Not Ideal for Certain Media: They may not be suitable for handling media with particles, high viscosity, or a tendency to clog, limiting their application in specific environments.

Precise Flow Control: Stainless steel globe valves excel in regulating fluid flow with precision, making them suitable for applications that require accurate control over the flow rate.

Versatility in Media Handling: These valves are adaptable to a diverse range of media, including corrosive and abrasive fluids, showcasing their versatility in different industrial settings.

Reliable Sealing Mechanism: The sealing mechanism, often involving wear-resistant surfaces and a dual-seal design, ensures reliable performance and minimizes the risk of leaks.

Controlled Flow Direction: Stainless steel globe valves provide precise control over the flow direction, enhancing their effectiveness in various operational scenarios.

Robust Construction for Durability: Constructed from stainless steel, these valves exhibit durability and resilience, resulting in a longer service life and reduced maintenance requirements.

Zero Fluid Loss: The design of stainless steel globe valves allows for minimal fluid loss during operation, contributing to enhanced energy efficiency and a cleaner working environment.

2. Cons of Stainless Steel Globe Valves

Operational Challenges: These valves often require substantial force for operation, leading to higher operational torque and, in turn, increased energy consumption.

Limited Adjustability: Stainless steel globe valves may have constraints in terms of adjustability, limiting their suitability for applications that require frequent adjustments.

High Fluid Resistance: The intricate fluid passages within the valve body can result in elevated fluid resistance, leading to increased power requirements for fluid flow.

Not Ideal for Certain Media: They may not be suitable for handling media with particles, high viscosity, or a tendency to clog, limiting their application in specific environments.

Stainless steel globe valves, efficient and reliable, play a crucial role in modern industries. Their precision in flow control, adaptability, and durability make them key players. Despite operational challenges and considerations, these valves remain a cornerstone for fluid dynamics in industrial processes.