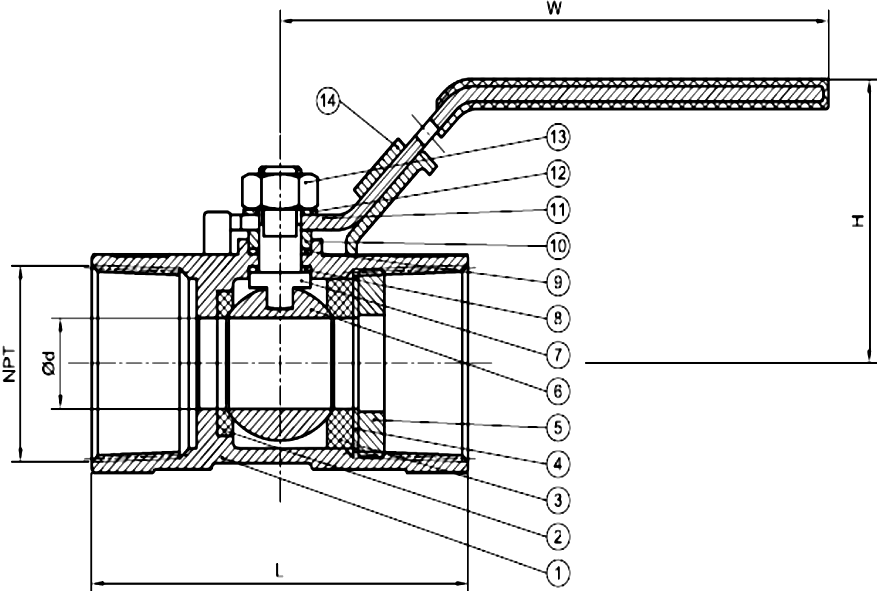

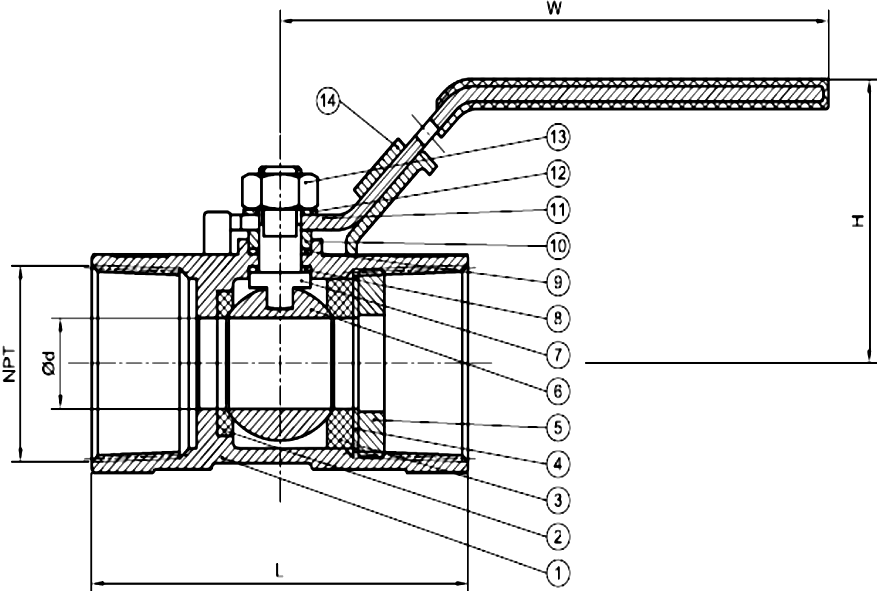

Working Mechanism and Advantages of One-Piece Ball Valves

A one-piece ball valve, a prevalent type of ball valve, employs a spherical closure element that revolves around the valve's central axis for the facilitation of opening and closing. This section provides a detailed exploration of the operational dynamics and benefits associated with this particular ball valve design.

Operational Dynamics of One-Piece Ball Valves

The operational dynamics of one-piece ball valves involve a precise sequence of actions during both the opening and closing processes:

The Noteworthy Advantages of One-Piece Ball Valves

The advantages of one-piece ball valves are notable for their impact on fluid control systems. Here's an exploration of the noteworthy benefits:

Categorization and Practical Guidelines

One-piece ball valves fall into categories based on channel positioning – straight-through, three-piece, and right-angle types. The latter two find application in medium distribution and flow direction alterations.

Installation and Maintenance Insights:

This comprehensive examination provides an in-depth analysis of the operational mechanisms, advantages, categorization, as well as practical guidelines for the installation and maintenance of one-piece ball valves. By thoroughly exploring these aspects, we aim to offer a nuanced understanding of the intricacies associated with the design, functionality, and effective utilization of one-piece ball valves across diverse applications.

Operational Dynamics of One-Piece Ball Valves

The operational dynamics of one-piece ball valves involve a precise sequence of actions during both the opening and closing processes:

1. Opening Process

Initial Configuration: The ball experiences mechanical pressure from the valve stem, firmly pressed against the valve seat.

Counter-clockwise Handle Rotation: The valve stem moves oppositely, prompting the ball to disengage from the valve seat.

Elevation of the Stem: Interaction between the valve stem and a guide pin enables the ball to rotate smoothly without encountering friction.

Attaining Full Openness: The valve stem reaches its maximum elevation, and the ball rotates to achieve a fully open position.

2. Closure Process

Clockwise Handle Rotation: The valve stem descends, causing the ball to lift off the valve seat and commence rotation.

Guide Pin Interaction: Simultaneous 90° rotation of the valve stem and ball.

Contact-free Rotation: The ball completes a 90° rotation without contacting the valve seat.

Seamless Sealing: In the final rotations, the valve stem's base mechanically wedges against the ball, ensuring a tight seal on the valve seat.

Initial Configuration: The ball experiences mechanical pressure from the valve stem, firmly pressed against the valve seat.

Counter-clockwise Handle Rotation: The valve stem moves oppositely, prompting the ball to disengage from the valve seat.

Elevation of the Stem: Interaction between the valve stem and a guide pin enables the ball to rotate smoothly without encountering friction.

Attaining Full Openness: The valve stem reaches its maximum elevation, and the ball rotates to achieve a fully open position.

2. Closure Process

Clockwise Handle Rotation: The valve stem descends, causing the ball to lift off the valve seat and commence rotation.

Guide Pin Interaction: Simultaneous 90° rotation of the valve stem and ball.

Contact-free Rotation: The ball completes a 90° rotation without contacting the valve seat.

Seamless Sealing: In the final rotations, the valve stem's base mechanically wedges against the ball, ensuring a tight seal on the valve seat.

The Noteworthy Advantages of One-Piece Ball Valves

The advantages of one-piece ball valves are notable for their impact on fluid control systems. Here's an exploration of the noteworthy benefits:

- Fluid Dynamics Excellence: The spherical closure design translates to minimal fluid resistance, with a coefficient matching that of an equivalent pipe segment.

- Structural Ingenuity: The simplistic design, compact size, and lightweight nature contribute to easy installation and maintenance.

- Dependability: A secure and dependable solution, often incorporating plastic or similar sealing materials, rendering it suitable for vacuum systems.

- User-Friendly Operation: Swift opening and closing with a 90° rotation, fostering convenience in remote control applications.

- Maintenance Simplification: The straightforward structure featuring movable sealing rings facilitates effortless disassembly and replacement.

- Corrosion Resilience: During full openness or closure, the isolation of the ball and valve seat's sealing surfaces from the medium prevents erosion.

- Versatile Applicability: Suitable for a diverse range of diameters, spanning from a few millimeters to several meters, applicable across high vacuum to high-pressure scenarios.

Categorization and Practical Guidelines

One-piece ball valves fall into categories based on channel positioning – straight-through, three-piece, and right-angle types. The latter two find application in medium distribution and flow direction alterations.

Installation and Maintenance Insights:

Reserved Rotation Space: Ensuring sufficient space for smooth handle rotation enhances operational efficiency.

Unsuited for Throttling: While excellent for quick opening and closing, caution is advised against employing these valves for throttling applications.

Actuation Mechanism Alignment: Ball valves with actuation mechanisms should be installed in an upright position for optimal functionality.

Unsuited for Throttling: While excellent for quick opening and closing, caution is advised against employing these valves for throttling applications.

Actuation Mechanism Alignment: Ball valves with actuation mechanisms should be installed in an upright position for optimal functionality.

This comprehensive examination provides an in-depth analysis of the operational mechanisms, advantages, categorization, as well as practical guidelines for the installation and maintenance of one-piece ball valves. By thoroughly exploring these aspects, we aim to offer a nuanced understanding of the intricacies associated with the design, functionality, and effective utilization of one-piece ball valves across diverse applications.