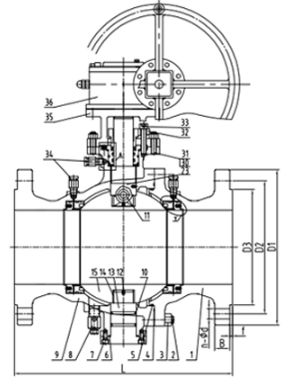

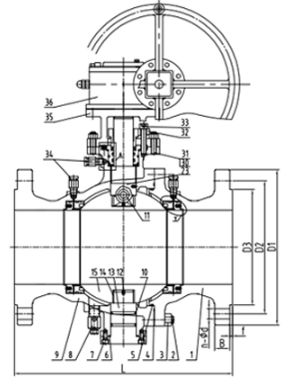

Twin Seal Plug Valve: Precision Operation and Key Advantages

The Twin Seal Plug Valve is a versatile device widely employed in industrial valve applications. Renowned for its distinctive structure and operational principles, this plug valve plays a pivotal role in liquid control systems. Below, we delve into a detailed explanation of its working principles and highlight the notable features and advantages.

Operation of Twin Seal Plug Valve

The Twin Seal Plug Valve stands out as a precision performer in fluid control systems. Its operation is characterized by a seamless opening and closing process, ensuring efficient and reliable valve performance. This brief introduction explores the key aspects of the Twin Seal Plug Valve's operation, highlighting its unique features that contribute to precision fluid control.

Double-Sealing Mechanism

The Twin Seal Plug Valve adopts the innovative approach of employing two independent sealing sliders to press against the upper and lower ends of the valve hole, establishing a dual-sealing mechanism. During valve closure, the relief valve is opened for inspecting the sealing effectiveness, thereby ensuring optimal sealing performance.

Major Features and Advantages

The Twin Seal Plug Valve is an optimal solution in fluid control, known for its advanced features that enhance performance and reliability. Below, we delve into its major features and advantages, showcasing the innovative design elements that make it a preferred choice in industrial applications.

In summary, the Twin Seal Plug Valve delivers precision in fluid control with seamless opening and closing processes. Its advanced features, including frictionless operation, easy maintenance, cost efficiency, and fire-resistant seals, highlight its superiority in industrial applications. With a commitment to operational excellence and a precision valve status indication, the Twin Seal Plug Valve stands as a reliable and efficient solution for diverse fluid control needs.

Operation of Twin Seal Plug Valve

The Twin Seal Plug Valve stands out as a precision performer in fluid control systems. Its operation is characterized by a seamless opening and closing process, ensuring efficient and reliable valve performance. This brief introduction explores the key aspects of the Twin Seal Plug Valve's operation, highlighting its unique features that contribute to precision fluid control.

1. Valve Opening Process

Initiating the valve opening entails rotating the handwheel, elevating the plug, and retracting the sealing slider from the sealing surfaces on both sides of the valve body. Once fully detached, continued rotation of the handwheel by 90° positions the valve in the open state, ensuring a seamless and controlled opening.

2. Valve Closing Process

Closing the valve involves a similar rotational movement of the handwheel, causing the plug and sealing slider to rotate by 90°. The subsequent downward movement of the plug pushes the sealing slider towards the internal face of the valve body, achieving an effective seal by compressing the elastic sealing ring uniformly at the upper and lower ends of the valve hole. This meticulous process ensures a secure and reliable valve closure.

Initiating the valve opening entails rotating the handwheel, elevating the plug, and retracting the sealing slider from the sealing surfaces on both sides of the valve body. Once fully detached, continued rotation of the handwheel by 90° positions the valve in the open state, ensuring a seamless and controlled opening.

2. Valve Closing Process

Closing the valve involves a similar rotational movement of the handwheel, causing the plug and sealing slider to rotate by 90°. The subsequent downward movement of the plug pushes the sealing slider towards the internal face of the valve body, achieving an effective seal by compressing the elastic sealing ring uniformly at the upper and lower ends of the valve hole. This meticulous process ensures a secure and reliable valve closure.

Double-Sealing Mechanism

The Twin Seal Plug Valve adopts the innovative approach of employing two independent sealing sliders to press against the upper and lower ends of the valve hole, establishing a dual-sealing mechanism. During valve closure, the relief valve is opened for inspecting the sealing effectiveness, thereby ensuring optimal sealing performance.

Major Features and Advantages

The Twin Seal Plug Valve is an optimal solution in fluid control, known for its advanced features that enhance performance and reliability. Below, we delve into its major features and advantages, showcasing the innovative design elements that make it a preferred choice in industrial applications.

Frictionless Operation: Zero contact between the valve body sealing surface and the slider sealing surface during opening and closing, contributing to zero friction and zero wear, ultimately extending the valve's lifespan.

Convenient Maintenance: The valve's maintenance is simplified, requiring only the opening of the valve bottom cover to replace a pair of sliders, eliminating the need for valve removal.

Cost Efficiency: The tapered design of the valve body and plug reduces costs, enhancing economic viability.

Robust Internal Coating: The valve body's internal chamber is hard chrome-plated, creating a durable and smooth sealing area.

Fire-Resistant Seals: The elastic seal, utilizing fluororubber, is complemented by a metal-to-metal seal, providing fire-resistant properties.

Automatic Relief Device: Prevents abnormal pressure rise in the valve chamber and facilitates post-closure inspection of the valve's effectiveness.

Precision Valve Status Indication: The valve switch indicator synchronizes with the switch position, accurately displaying the valve's open or closed status.

Convenient Maintenance: The valve's maintenance is simplified, requiring only the opening of the valve bottom cover to replace a pair of sliders, eliminating the need for valve removal.

Cost Efficiency: The tapered design of the valve body and plug reduces costs, enhancing economic viability.

Robust Internal Coating: The valve body's internal chamber is hard chrome-plated, creating a durable and smooth sealing area.

Fire-Resistant Seals: The elastic seal, utilizing fluororubber, is complemented by a metal-to-metal seal, providing fire-resistant properties.

Automatic Relief Device: Prevents abnormal pressure rise in the valve chamber and facilitates post-closure inspection of the valve's effectiveness.

Precision Valve Status Indication: The valve switch indicator synchronizes with the switch position, accurately displaying the valve's open or closed status.

In summary, the Twin Seal Plug Valve delivers precision in fluid control with seamless opening and closing processes. Its advanced features, including frictionless operation, easy maintenance, cost efficiency, and fire-resistant seals, highlight its superiority in industrial applications. With a commitment to operational excellence and a precision valve status indication, the Twin Seal Plug Valve stands as a reliable and efficient solution for diverse fluid control needs.