The DBB ball valve, namely the double block and bleed ball valve, is widely recognized in the industrial sector for its unique design and multi-functionality, making it an ideal choice for fluid control applications. This article will delve into the structure, features, and advantages of the DBB ball valve, showcasing its exceptional performance in various operating conditions.

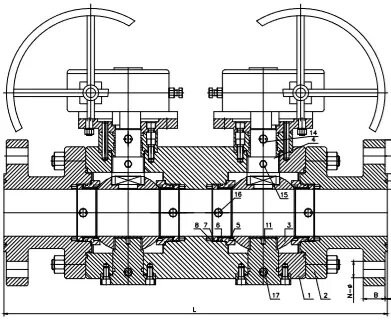

The structural features of a DBB ball valve contribute to its unique design and functionality. Here are the key structural features of a DBB ball valve:

The DBB double block and bleed ball valve require only a 90° rotation for both opening and closing, with a minimal torque needed for secure closure. The equal design of the valve body provides a low-resistance, straight-through flow path, making it suitable for diverse media.

The valve's ball has no supporting shaft and is supported by the valve seats at both the inlet and outlet ends. The ball's rotation, achievable through a handle or other driving devices, enables it to be used for flow control.

The stem is equipped with a downward-sealing structure with sealing gaskets, preventing the stem from being blown out. The rational design of the V-shaped structure converts medium pressure and the locking force from the external pressure cap into sealing force on the stem.

The DBB double block and bleed ball valve incorporate various protective measures, including anti-blowout stem, fire-resistant structure, lockable design, and an anti-static structure, ensuring safe operation in diverse environments.

DBB ball valves offer several advantages in industrial applications, making them a preferred choice for various fluid control scenarios. Here are the key advantages of DBB ball valves.

2. Simple and Lightweight Structure: Its compact design makes it suitable for various spaces, and its lightweight allows for easy handling and installation.

3. Tight and Reliable: With excellent sealing properties, using materials like plastics, the valve is widely applicable in vacuum systems.

4. Convenient Operation: A 90° rotation facilitates quick switching between fully open and fully closed positions, making it suitable for remote control.

5. Easy Maintenance: The simple structure and movable sealing rings make maintenance a convenient process.

6. Media Isolation: In fully open or fully closed states, the sealing surfaces of the ball and valve seats isolate the medium, preventing erosion of the valve sealing surfaces.

7. Wide Applicability: With a range of diameters from a few millimeters to several meters, the valve is suitable for various conditions, from high vacuum to high pressure.

The DBB double block and bleed ball valve play a crucial role in industrial fluid control, thanks to its compact structure, flexible operation, and broad applicability. Its advanced design and versatility make it an indispensable component in fluid control systems, providing reliable and secure solutions for diverse operating conditions.