Pneumatic Actuated Butterfly Valves: Double Acting and Single Acting Mechanisms

Pneumatic actuated butterfly valves, consisting of a pneumatic actuator and a butterfly valve, find extensive applications in low-pressure large-diameter pipelines, primarily serving as shut-off valves. This article provides a detailed exploration of the operational principles of pneumatic actuated butterfly valves, covering both double-acting and single-acting types.

Overview of Pneumatic Actuated Butterfly Valves

The basic components of pneumatic actuated butterfly valves include a pneumatic actuator and a butterfly valve. The circular disc, driven by the valve stem's rotation, accomplishes the opening and closing actions. Pneumatic actuated butterfly valves are not only employed as shut-off valves but can also be designed with regulating or throttling functions, expanding their applications in low-pressure large-diameter pipelines.

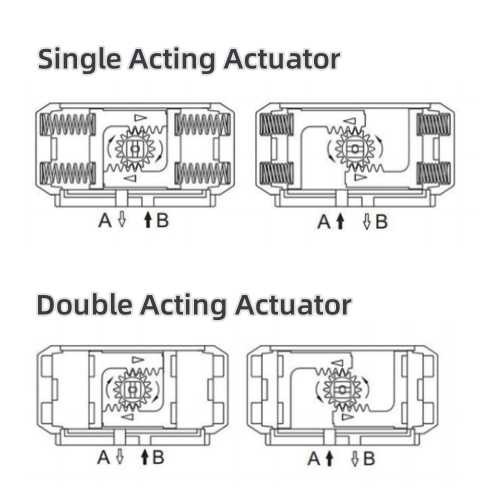

Exploring Double Acting Pneumatic Actuated Butterfly Valves

Double-acting pneumatic actuated butterfly valves feature two chambers on the left and right, operating as follows:

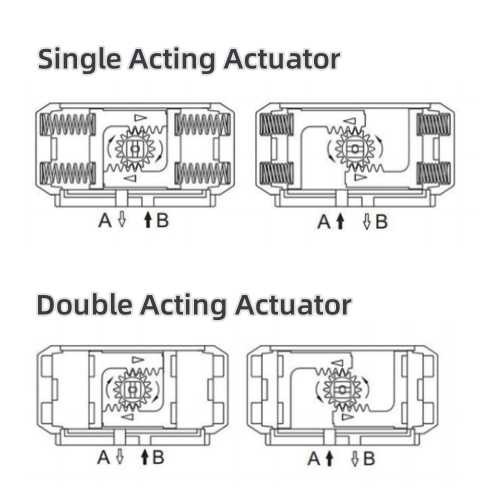

Decoding Single Acting Pneumatic Actuated Butterfly Valves

The operational principles of single-acting pneumatic actuated butterfly valves are outlined as follows:

In conclusion, understanding the operational principles of pneumatic actuated butterfly valves empowers professionals to choose the right valve types for fluid control applications. The distinction between double-acting and single-acting mechanisms allows tailored selections based on specific needs, optimizing performance in low-pressure large-diameter pipelines. This knowledge is a valuable resource for ensuring efficient fluid control systems across diverse industrial applications.

Overview of Pneumatic Actuated Butterfly Valves

The basic components of pneumatic actuated butterfly valves include a pneumatic actuator and a butterfly valve. The circular disc, driven by the valve stem's rotation, accomplishes the opening and closing actions. Pneumatic actuated butterfly valves are not only employed as shut-off valves but can also be designed with regulating or throttling functions, expanding their applications in low-pressure large-diameter pipelines.

Exploring Double Acting Pneumatic Actuated Butterfly Valves

Double-acting pneumatic actuated butterfly valves feature two chambers on the left and right, operating as follows:

1. Input of Air Signal: Air signal pressures, output by the double-acting positioner, are respectively fed into the left and right chambers of the actuator.

2. Pressure Differential Formation: The pressure difference between the air sources on both sides creates a pressure differential between the chambers.

3. Piston Motion Drive: The pressure differential propels the piston in a linear motion. Through gear and rack transmission, the linear motion of the piston is converted into the rotational motion of the actuator's spindle.

4. Flow Regulation: When flow adjustment is needed, the rotational movement of the actuator simultaneously drives the valve stem and core to rotate, altering the flow area between the valve core and seat to achieve the desired regulation.

5. Balanced Stop: Motion halts when the pressures in the left and right chambers balance.

2. Pressure Differential Formation: The pressure difference between the air sources on both sides creates a pressure differential between the chambers.

3. Piston Motion Drive: The pressure differential propels the piston in a linear motion. Through gear and rack transmission, the linear motion of the piston is converted into the rotational motion of the actuator's spindle.

4. Flow Regulation: When flow adjustment is needed, the rotational movement of the actuator simultaneously drives the valve stem and core to rotate, altering the flow area between the valve core and seat to achieve the desired regulation.

5. Balanced Stop: Motion halts when the pressures in the left and right chambers balance.

Decoding Single Acting Pneumatic Actuated Butterfly Valves

The operational principles of single-acting pneumatic actuated butterfly valves are outlined as follows:

1. Input of Air Signal Pressure: The air signal pressure, output by the single-acting positioner, is directed into the actuator's chamber without a spring.

2. Linear Motion: The cylinder piston undergoes linear motion due to the pressure difference between the applied air signal pressure and the spring force.

3. Balanced Stop: Gear and rack transmission balance the thrust generated by the air signal pressure with the spring force, bringing the motion to a stop.

4. Flow Regulation: Simultaneously, as the actuator's spindle rotates, the valve stem and core follow suit, modifying the flow area between the valve core and seat for regulation purposes.

2. Linear Motion: The cylinder piston undergoes linear motion due to the pressure difference between the applied air signal pressure and the spring force.

3. Balanced Stop: Gear and rack transmission balance the thrust generated by the air signal pressure with the spring force, bringing the motion to a stop.

4. Flow Regulation: Simultaneously, as the actuator's spindle rotates, the valve stem and core follow suit, modifying the flow area between the valve core and seat for regulation purposes.

In conclusion, understanding the operational principles of pneumatic actuated butterfly valves empowers professionals to choose the right valve types for fluid control applications. The distinction between double-acting and single-acting mechanisms allows tailored selections based on specific needs, optimizing performance in low-pressure large-diameter pipelines. This knowledge is a valuable resource for ensuring efficient fluid control systems across diverse industrial applications.