Elevating Fluid Control with the Piston Check Valve

Introducing a new era in fluid control, the piston check valve distinguishes itself with its ingenious design and versatile applications. Explore the key features of this check valve, including advanced buffer design and seamless backflow protection, to understand why it has become the preferred solution for contemporary industrial systems.

Piston Check Valve Introduction

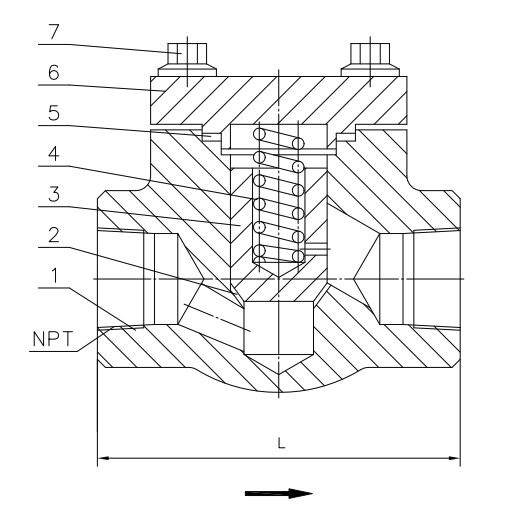

The piston check valve is essentially a lift-type check valve, equipped with a buffer consisting of a piston and cylinder that provides cushioning during operation. Its flow characteristics are similar to lift-type check valves, with the medium entering from below the valve seat. The installation method mirrors that of lift-type check valves. This valve structure aligns with lift-type check valves and is commonly applied alongside globe valves and angle valves in pipeline systems where the direction of the medium frequently changes, encompassing areas such as water supply, steam, and air systems.

Structure and Features

Buffer Design: The piston check valve employs a unique buffer design, allowing for uninterrupted application in fields such as water pumps and reciprocating compressors, preventing failures due to common check valve wear.

Ease of Maintenance: The top-mounted design facilitates easy online inspection and replacement of internal components, minimizing downtime.

Backflow Protection: In the absence of pressure differential, the piston check valve, through the action of the valve chamber and spring, returns to the closed position, effectively preventing backflow.

Characteristics and Advantages

Multiple Sealing Options: Offers a choice between soft and hard sealing, with the ability to replace the valve seat.

Diverse Material Selection: Provides a variety of valve body and internal material options to accommodate different medium requirements.

Better Seal with Higher Back Pressure: The design of the piston and valve seat ensures a better seal as back pressure increases.

Versatile Installation: Typically suitable for horizontal installation; for vertical installations, consultation with the valve manufacturer is recommended.

Application Scenarios

Pipelines with Flow Fluctuations: Recommended for use in pipelines with flow fluctuations, such as outlet pipes of reciprocating compressors and pumps.

Pressure Fluctuation Systems: In systems where the medium experiences sudden pressure increases and fluctuations, the piston check valve reliably safeguards the system.

The piston check valve, with its unique design, plays a crucial role in the system by not only protecting it from the impacts of pressure fluctuations but also gaining favor for its convenient maintenance features. When choosing this valve, users should clearly define operating conditions to meet specific medium requirements.

Piston Check Valve Introduction

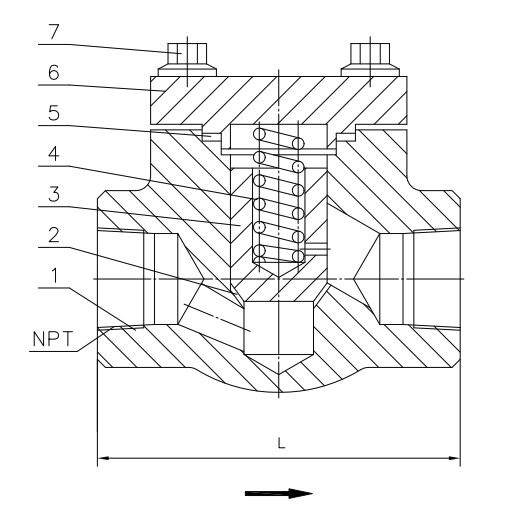

The piston check valve is essentially a lift-type check valve, equipped with a buffer consisting of a piston and cylinder that provides cushioning during operation. Its flow characteristics are similar to lift-type check valves, with the medium entering from below the valve seat. The installation method mirrors that of lift-type check valves. This valve structure aligns with lift-type check valves and is commonly applied alongside globe valves and angle valves in pipeline systems where the direction of the medium frequently changes, encompassing areas such as water supply, steam, and air systems.

Structure and Features

Buffer Design: The piston check valve employs a unique buffer design, allowing for uninterrupted application in fields such as water pumps and reciprocating compressors, preventing failures due to common check valve wear.

Ease of Maintenance: The top-mounted design facilitates easy online inspection and replacement of internal components, minimizing downtime.

Backflow Protection: In the absence of pressure differential, the piston check valve, through the action of the valve chamber and spring, returns to the closed position, effectively preventing backflow.

Characteristics and Advantages

Multiple Sealing Options: Offers a choice between soft and hard sealing, with the ability to replace the valve seat.

Diverse Material Selection: Provides a variety of valve body and internal material options to accommodate different medium requirements.

Better Seal with Higher Back Pressure: The design of the piston and valve seat ensures a better seal as back pressure increases.

Versatile Installation: Typically suitable for horizontal installation; for vertical installations, consultation with the valve manufacturer is recommended.

Application Scenarios

Pipelines with Flow Fluctuations: Recommended for use in pipelines with flow fluctuations, such as outlet pipes of reciprocating compressors and pumps.

Pressure Fluctuation Systems: In systems where the medium experiences sudden pressure increases and fluctuations, the piston check valve reliably safeguards the system.

The piston check valve, with its unique design, plays a crucial role in the system by not only protecting it from the impacts of pressure fluctuations but also gaining favor for its convenient maintenance features. When choosing this valve, users should clearly define operating conditions to meet specific medium requirements.