Metal Seated Lubricated Plug Valve, API 599, API 6D, 1/2-16 IN

Key Specifications / Features

Model No.: JSC-231215-PBPV-04

Hits: 111

Introducing our Metal Seated Lubricated Plug Valve, expertly produced by a leading manufacturer in China. Designed with a pressure-balanced feature, this valve adheres to API 6D and API 599 standards. Available in sizes ranging from 1/2 to 16 inches (DN15-DN400) and with class ratings of 150-900 LB, it is crafted from high-quality alloy and stainless steel. Trust our commitment to quality for your metal-seated lubricated plug valve needs.

Request a quote

Tags

Detail Information

Metal Seated Lubricated Plug Valve Introduction

Metal seated lubricated plug valve can be designed according to ANSI standard, and metal seated lubricated plug valve was widely applied for petroleum, chemical industry, pharmacy, chemical fertilizer, power industry etc. Lubricated plug valve can be called as Pressure balance lubricated plug valve, and the main application of Metal seated lubricated plug valve is cutting and connecting the pipeline medium with pressure class 150 to class 2500 LB under the temperature -29 ℃ to +180 ℃ or -40 ℃~450 ℃.

Metal Seated Lubricated Plug Valve Main Characteristics

1. There are compact structure, reliable sealing, perfect function and attractive shape for lubricated plug valve natural gas.

2. Metal seated lubricated plug valve is Inverted pressure balance structure, easy to be opened or closed.

3. There is a oil groove between lubricated plug valve body and sealing surface, the sealing grease can be injected into the seat through glib (oil nozzle) to increase the sealing performance.

4. For the spare parts material and flange size, Metal seated lubricated plug valve can be customized according to different actual working condition to meet project requirements.

Metal Seated Lubricated Plug Valve Technical Specification

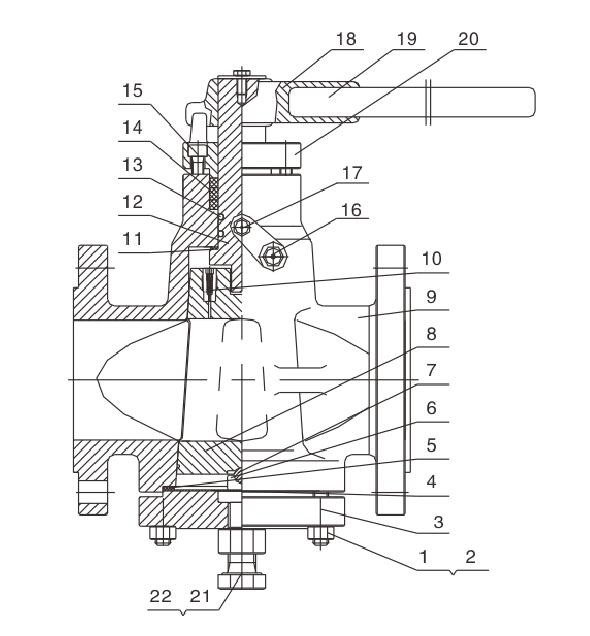

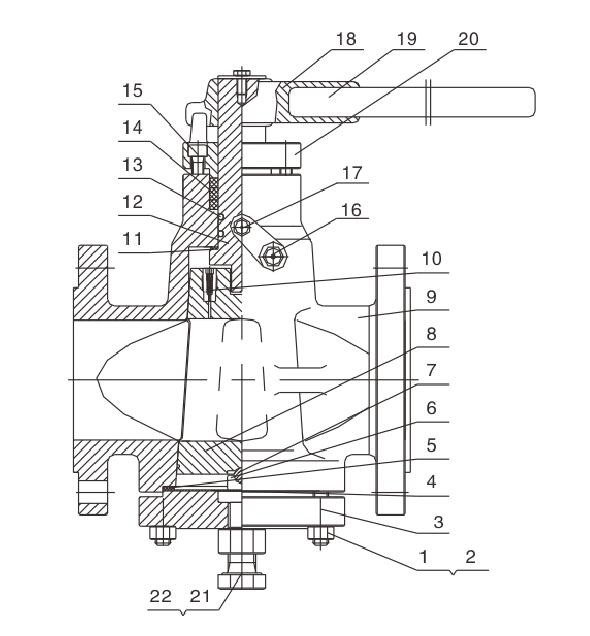

Metal Seated Lubricated Plug Valve Structure

Metal Seated Lubricated Plug Valve Main Parts Material

Metal seated lubricated plug valve can be designed according to ANSI standard, and metal seated lubricated plug valve was widely applied for petroleum, chemical industry, pharmacy, chemical fertilizer, power industry etc. Lubricated plug valve can be called as Pressure balance lubricated plug valve, and the main application of Metal seated lubricated plug valve is cutting and connecting the pipeline medium with pressure class 150 to class 2500 LB under the temperature -29 ℃ to +180 ℃ or -40 ℃~450 ℃.

Metal Seated Lubricated Plug Valve Main Characteristics

1. There are compact structure, reliable sealing, perfect function and attractive shape for lubricated plug valve natural gas.

2. Metal seated lubricated plug valve is Inverted pressure balance structure, easy to be opened or closed.

3. There is a oil groove between lubricated plug valve body and sealing surface, the sealing grease can be injected into the seat through glib (oil nozzle) to increase the sealing performance.

4. For the spare parts material and flange size, Metal seated lubricated plug valve can be customized according to different actual working condition to meet project requirements.

Metal Seated Lubricated Plug Valve Technical Specification

| Design & manufacture | API 599, API 6D |

| Nominal diameter | 1/2 Inch - 16 Inch ( DN15 - DN400) |

| Pressure class | Class 150 - 900 LB |

| Length of face to face | ASME B16.10 |

| Flange end | ASME B16.5 |

| Test & inspection | API 598, API 6D |

| Operation model | Handle wheel, worm gear, pneumatic and electric actuated |

Metal Seated Lubricated Plug Valve Structure

Metal Seated Lubricated Plug Valve Main Parts Material

| NO | Part Name | Material |

| 1 | Body | ASTM A216 WCB, ASTM A217 WC1, WC6, WC9, C5, ASTM A351 CF8, CF8M, CF3, CF3M |

| 2 | Plug | ASTM A182 Gr. F6a, ASTM A182 F22, ASTM A217 WC1, WC6, WC9, C5, ASTM A351 CF8, CF8M, CF3, CF3M |

| 3 | Gasket | Flexible graphite+stainless steel |

| 4 | Cover | ASTM A216 WCB, ASTM A217 WC1, WC6, WC9, C5, ASTM A351 CF8, CF8M, CF3, CF3M |

| 5 | Bolt | ASTM A193 B7, A193 B8, A193 B8M |

| 6 | Nut | ASTM A194 2H, A194 Gr. 8, A194 Gr. 8M |

| 7 | Packing | Flexible graphite + SS 304 |

| 8 | Gland | ASTM A216 WCB, ASTM A217 WC1, WC6, WC9, C5, ASTM A351 CF8, CF8M, CF3, CF3M |

| 9 | Wrench | ASTM A216 WCB, ASTM A351 CF8, CF8M, CF3, CF3M |

| 10 | Yoke nut | ZQA 19-4 |

| 11 | Handwheel | ASTM A536 Gr. 60-40-18, ASTM A216 WCB |

Comment Form