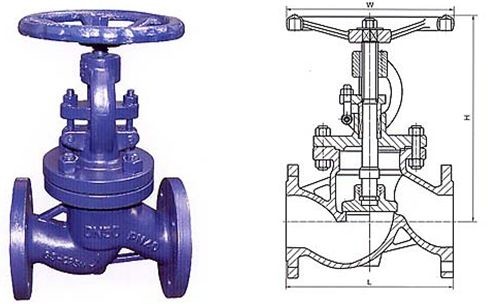

DIN Globe Valve, EN 13709, DIN 3356, 1/2-24 IN, 150-2500 LB

Key Specifications / Features

Model No.: JSC-231120-CSGV-64

Hits: 122

We are a trusted supplier of DIN globe valves in China, offering a comprehensive range that adheres to standards such as EN 13709 and DIN 3356. Our valves come in sizes ranging from 1/2 to 24 inches (DN15 to DN600) with pressure ratings of Class 150 LB to 2500 LB and PN20 to PN420. Crafted from materials including GS-C25, GP240GH, 1.4308, 1.4408, and Monel, our DIN globe valves are designed to meet diverse specifications for various applications. Trust us for reliable and high-quality valves that meet international standards.

Request a quote

Tags

Detail Information

DIN Globe Valve

Our DIN globe valve has reasonable structure and reliable sealing, especially suitable for flammable, explosive, highly toxic and toxic fluids, high temperature heat transfer oil, liquid ammonia, glycol and other media, with nominal pressure of PN16~PN160 and working temperature of – 29 ~ 350 ℃. DIN globe valve drive modes include manual, gear drive, electric, pneumatic, etc.

It is widely used in petrochemical industry, chemical fiber textile, plastic papermaking, electric power steel, printing and dyeing rubber, natural gas and other gas systems, with safe and reliable performance.

DIN Globe Valve-Structure Feature

1. The design and manufacture of the products meet the requirements of American national standard EN13709/DIN3356 and other foreign advanced standards.

2. The shape of valve body is barrel shape or streamline shape, which is beautiful. The flow pattern is straight through. The fluid resistance is small.

3. The sealing surface of the closing part (disc) and valve seat is sealed with conical surface, which has small closing force, erosion resistance and reliable sealing.

4. The valve seat can be a replaceable valve seat, which can be combined with the sealing surface material to meet the requirements of working conditions and prolong the service life.

5. According to the need of closing force, the large diameter and high pressure stop valve adopts the lifting rod as the driving mode, and is equipped with rolling bearing type and impact type hand wheel to reduce the closing force.

6. The materials of main body, inner parts, fillers and fasteners can be reasonably combined according to the requirements of users or actual working conditions.

DIN Globe Valve-Specifications and Materials

Design and manufacture: EN 13709, DIN 3356

Face to face dimensions: EN 558, DIN 3202

Flange ends: EN 1092-1, DIN 2543, DIN 2544, DIN 2545

Valves Marking: MSS SP-25

Inspection and testing: EN12266

Body material: GP240GH, 1.0619, GS-C25, G-X6CrNi18.9, 1.4308, G-X6CrNiMo18.10, 1.4408, ASTM A216 WCB, WCC, ASTM A217 WC1, WC6, WC9, ASTM A351 CF8, CF8M, CF3, CF3M, CN7M, ASTM A352 LC1, LCB, LCC, LC3 or by customers (Cast Steel, Alloy Steel, Stainless Steel, Special Steel)

Trim material: ASTM A216 WCB, ASTM A352 LCB, ASTM A105, Alloy Steel, ASTM A217 WC6 WC9, ASTM A182 F11, Stainless Steel, ASTM A351 CF8, CF8M, CF3, CF3M, ASTM A182 F304, F316, F304L, F316L, Duplex SS, ASTM A890 4A, 5A, ASTM A182 F51, F55, special alloy, Monel, Bronze C95800, Alloy 20

Size range: 1/2 Inch - 24 Inch (DN15 - DN600)

Pressure range: Class 150 LB - 2500 LB (PN20 – PN420)

Drive Mode: Manual, Worm gear, Electric, Pneumatic

Field of Application: Electric /Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

TECHNICAL SPECIFICATIONS

Product Performance Specification

Material and Performance of Main Parts

DIN Globe Valve

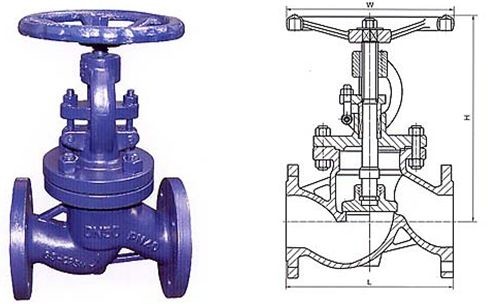

Main Shape and Connection Dimension

Main Shape and Connection Dimension

Our DIN globe valve has reasonable structure and reliable sealing, especially suitable for flammable, explosive, highly toxic and toxic fluids, high temperature heat transfer oil, liquid ammonia, glycol and other media, with nominal pressure of PN16~PN160 and working temperature of – 29 ~ 350 ℃. DIN globe valve drive modes include manual, gear drive, electric, pneumatic, etc.

It is widely used in petrochemical industry, chemical fiber textile, plastic papermaking, electric power steel, printing and dyeing rubber, natural gas and other gas systems, with safe and reliable performance.

DIN Globe Valve-Structure Feature

1. The design and manufacture of the products meet the requirements of American national standard EN13709/DIN3356 and other foreign advanced standards.

2. The shape of valve body is barrel shape or streamline shape, which is beautiful. The flow pattern is straight through. The fluid resistance is small.

3. The sealing surface of the closing part (disc) and valve seat is sealed with conical surface, which has small closing force, erosion resistance and reliable sealing.

4. The valve seat can be a replaceable valve seat, which can be combined with the sealing surface material to meet the requirements of working conditions and prolong the service life.

5. According to the need of closing force, the large diameter and high pressure stop valve adopts the lifting rod as the driving mode, and is equipped with rolling bearing type and impact type hand wheel to reduce the closing force.

6. The materials of main body, inner parts, fillers and fasteners can be reasonably combined according to the requirements of users or actual working conditions.

DIN Globe Valve-Specifications and Materials

Design and manufacture: EN 13709, DIN 3356

Face to face dimensions: EN 558, DIN 3202

Flange ends: EN 1092-1, DIN 2543, DIN 2544, DIN 2545

Valves Marking: MSS SP-25

Inspection and testing: EN12266

Body material: GP240GH, 1.0619, GS-C25, G-X6CrNi18.9, 1.4308, G-X6CrNiMo18.10, 1.4408, ASTM A216 WCB, WCC, ASTM A217 WC1, WC6, WC9, ASTM A351 CF8, CF8M, CF3, CF3M, CN7M, ASTM A352 LC1, LCB, LCC, LC3 or by customers (Cast Steel, Alloy Steel, Stainless Steel, Special Steel)

Trim material: ASTM A216 WCB, ASTM A352 LCB, ASTM A105, Alloy Steel, ASTM A217 WC6 WC9, ASTM A182 F11, Stainless Steel, ASTM A351 CF8, CF8M, CF3, CF3M, ASTM A182 F304, F316, F304L, F316L, Duplex SS, ASTM A890 4A, 5A, ASTM A182 F51, F55, special alloy, Monel, Bronze C95800, Alloy 20

Size range: 1/2 Inch - 24 Inch (DN15 - DN600)

Pressure range: Class 150 LB - 2500 LB (PN20 – PN420)

Drive Mode: Manual, Worm gear, Electric, Pneumatic

Field of Application: Electric /Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

TECHNICAL SPECIFICATIONS

| STRUCTURE | BB-BG-OS&Y |

| Operator | Handwheel |

| Electrical | |

| Design | EN 13709/DIN 3356 |

| Face to face | EN 558/DIN 3202 |

| End flange | EN 1092-1/DIN 2543-2545 |

Product Performance Specification

| PN(MPa) | Shell test(MPa) | Sealing test(MPa) | Suitable temp.(℃) | Suitable media |

| 1.6 | 2.4 | 1.76 | -110~600℃ | Water, oil, stream etc |

| 2.5 | 3.75 | 2.75 | ||

| 4.0 | 6.0 | 4.4 | ||

| 6.4 | 9.6 | 7.04 |

Material and Performance of Main Parts

| Body | GS-C25/GP240GH | 1.4308 | |||||||||||

| Disc | GS-C25 | 1.4308 | 1.4408 | Monel | |||||||||

| Stem | 13Cr | 1.4308 | 1.4408 | Monel | F304 | ||||||||

| Disc seat | 13Cr | 13Cr | STL | 1.4308 | STL | 1.4408 | STL | Monel | 1.4308 | 1.4308 | STL | ||

| Body seat | 13Cr | STL | STL | 1.4308 | STL | 1.4408 | STL | Monel | 1.4308 | STL | STL | ||

| Shell | 1.4408 | 1.4306 | 1.4301 | ||||||||||

| Disc | |||||||||||||

| Stem | 1.4408 | 1.4306 | 1.4301 | ||||||||||

| Disc seat | 1.4408 | 1.4408 | STL | 1.4306 | 1.4306 | STL | 1.4301 | 1.4301 | STL | ||||

| Body seat | 1.4408 | STL | STL | 1.4306 | STL | STL | 1.4301 | STL | STL | ||||

DIN Globe Valve

Main Shape and Connection Dimension

| PN (MPa) | PN1.6 MPa | ||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 450 | 600 | 730 | 850 | 980 | 1100 | |

| H | 240 | 260 | 276 | 285 | 300 | 305 | 354 | 402 | 437 | 496 | 541 | 699 | 815 | 914 | 1189 | 1350 | |

| W | 120 | 140 | 160 | 160 | 180 | 200 | 200 | 750 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

| Weight (Kg) | 8 | 10 | 12 | 16 | 17 | 20 | 30 | 38 | 56 | 75 | 100 | 182 | 278 | 398 | 500 | 618 | |

| PN (MPa) | PN2.5MPa | |||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | |

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 450 | 600 | 730 | 850 | 980 | 1100 | ||

| H | 240 | 260 | 276 | 285 | 300 | 325 | 363 | 415 | 453 | 505 | 556 | 744 | 864 | 948 | 1269 | 1450 | ||

| W | 120 | 140 | 160 | 160 | 180 | 200 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 600 | ||

| Weight (Kg) | 8 | 10 | 12 | 16 | 17 | 20 | 30 | 39 | 58 | 80 | 101 | 190 | 290 | 405 | 510 | 650 | ||

| PN (MPa) | PN4.0MPa | |||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | |

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 450 | 600 | 730 | 850 | 980 | 1100 | ||

| H | 240 | 260 | 276 | 285 | 300 | 325 | 370 | 430 | 480 | 532 | 589 | 783 | 888 | 965 | 1285 | 1512 | ||

| W | 120 | 140 | 160 | 160 | 180 | 200 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 600 | ||

| Weight (Kg) | 8 | 10 | 12 | 16 | 17 | 22 | 31 | 41.5 | 61 | 83 | 110 | 210 | 318.5 | 430 | 520 | 680 | ||

| PN (MPa) | PN6.4MPa | |||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | |

| L | 130 | 150 | 160 | 180 | 200 | 300 | 340 | 380 | 430 | 500 | 550 | 650 | 775 | 900 | 1025 | 1150 | ||

| H | 240 | 260 | 276 | 285 | 300 | 305 | 354 | 402 | 437 | 495 | 541 | 699 | 815 | 914 | 1189 | 1350 | ||

| W | 120 | 140 | 160 | 160 | 180 | 200 | 200 | 750 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | ||

| Weight (Kg) | 8 | 10 | 12 | 16 | 17 | 20 | 30 | 38 | 56 | 75 | 100 | 182 | 278 | 398 | 500 | 618 | ||

| PN (MPa) | PN10.0MPa | |||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| L | 130 | 150 | 160 | 180 | 200 | 300 | 340 | 380 | 450 | 500 | 550 | 650 | 775 | 900 | 1025 | 1250 | |

| H | 240 | 260 | 276 | 285 | 300 | 325 | 363 | 415 | 453 | 505 | 556 | 744 | 864 | 948 | 1269 | 1450 | |

| W | 120 | 140 | 160 | 160 | 180 | 200 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 600 | |

| Weight (Kg) | 8 | 10 | 12 | 16 | 17 | 20 | 30 | 39 | 58 | 80 | 101 | 190 | 290 | 405 | 510 | 650 | |

| PN (MPa) | PN16.0MPa | ||||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| L | 130 | 150 | 160 | 180 | 200 | 300 | 340 | 380 | 450 | 500 | 550 | 650 | 775 | 900 | 1025 | 1250 | |

| H | 240 | 260 | 276 | 285 | 300 | 325 | 370 | 430 | 480 | 532 | 589 | 783 | 888 | 965 | 1285 | 1512 | |

| W | 120 | 140 | 160 | 160 | 180 | 200 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 600 | |

| Weight (Kg) | 8 | 10 | 12 | 16 | 17 | 22 | 31 | 41.5 | 61 | 83 | 110 | 210 | 318.5 | 430 | 520 | 680 | |

Comment Form