Y Pattern Globe Valve, ASME B16.34, 1/2-14 Inch, 150-2500 LB

Key Specifications / Features

Model No.: JSC-231120-CSGV-67

Hits: 80

As a leading producer of Y-pattern globe valves in China, our offerings adhere to stringent standards including BS 1873 and ASME B16.34. We provide a comprehensive range from 1/2 to 14 inches, catering to DN15 to DN300 specifications. The valves cover a diverse pressure spectrum, from Class 150 to 2500 LB and PN20 to PN420. Crafted from high-quality materials such as ASTM A216 WCB, A217 WC6, and A351 CF8, our Y-pattern globe valves are engineered for optimal performance and reliability across various applications.

Request a quote

Tags

Detail Information

Y Pattern Globe Valve

Our globe valve is suitable for cutting off or connecting pipeline medium in petroleum, chemical, pharmaceutical, chemical fertilizer, electric power industry and other working conditions with nominal pressure of PN1.6 ~ 16MPa and working temperature of - 29 ~ 550 ℃. There are manual drive, gear drive, electric, pneumatic and so on.

Y Pattern Globe Valve-Structure Feature

The structural features of high temperature and high pressure Y-type globe valve are as follows:

1. The wide sealing surface design can effectively prolong the service life of the sealing surface. The sealing surface is overlaid with STL alloy, which has good erosion resistance and wear resistance.

2. The inclined angle of Y-shape is 45 ° and the flow channel tends to be linear.

3. The valve disc is guided in the whole process, and the guide surface is overlaid with wear-resistant alloy, which has good wear resistance; after the valve body and valve disc are finished, the guide gap between the valve disc and the valve body is strictly controlled; the guide rib is set at the outlet port of the middle chamber of the large-diameter valve body, and the guiding surface is finished to prevent the valve disc from jamming at the valve outlet during the movement.

4. The valve adopts the pressure self tightening sealing structure in the middle chamber, which is reasonable in structure and suitable for high temperature and high pressure conditions.

5. The disc spring is installed on the packing compression bolt, which can effectively eliminate the influence of pressure fluctuation and high temperature on the valve stem seal.

Y Pattern Globe Valve-Specifications and Materials

Design standard: BS 1873, ASME B16.34, GB

Size: DN15 - DN350, 1/2 Inch - 14 Inch

Class: Class 150 LB – 2500 LB, PN20 - PN420

Test standard: API 598

Face to face: ANSI B 16.10

End connection: ASME B16.5, ASME B16.25, GB/T 9113, GB/T 12224

Body material: ASTM A216 WCB, WCC; ASTM A217 WC6, WC9, C5, C12, C12A, CA15; ASTM A351 CF8, CF8M, CF3, CF3M, CF8C, CN3MN, CK3MCUN, CN7M; ASTM A352 LCB, LCC; ASTM A494 CW-6MC, CU5MCuC, M35-1; ASTM A890 4A (CD3MN), 5A(CE3MN), 6A(CD3MWCuN); ASME B148 C95800, C95500

Our globe valve is suitable for cutting off or connecting pipeline medium in petroleum, chemical, pharmaceutical, chemical fertilizer, electric power industry and other working conditions with nominal pressure of PN1.6 ~ 16MPa and working temperature of - 29 ~ 550 ℃. There are manual drive, gear drive, electric, pneumatic and so on.

Y Pattern Globe Valve-Structure Feature

The structural features of high temperature and high pressure Y-type globe valve are as follows:

1. The wide sealing surface design can effectively prolong the service life of the sealing surface. The sealing surface is overlaid with STL alloy, which has good erosion resistance and wear resistance.

2. The inclined angle of Y-shape is 45 ° and the flow channel tends to be linear.

3. The valve disc is guided in the whole process, and the guide surface is overlaid with wear-resistant alloy, which has good wear resistance; after the valve body and valve disc are finished, the guide gap between the valve disc and the valve body is strictly controlled; the guide rib is set at the outlet port of the middle chamber of the large-diameter valve body, and the guiding surface is finished to prevent the valve disc from jamming at the valve outlet during the movement.

4. The valve adopts the pressure self tightening sealing structure in the middle chamber, which is reasonable in structure and suitable for high temperature and high pressure conditions.

5. The disc spring is installed on the packing compression bolt, which can effectively eliminate the influence of pressure fluctuation and high temperature on the valve stem seal.

Y Pattern Globe Valve-Specifications and Materials

Design standard: BS 1873, ASME B16.34, GB

Size: DN15 - DN350, 1/2 Inch - 14 Inch

Class: Class 150 LB – 2500 LB, PN20 - PN420

Test standard: API 598

Face to face: ANSI B 16.10

End connection: ASME B16.5, ASME B16.25, GB/T 9113, GB/T 12224

Body material: ASTM A216 WCB, WCC; ASTM A217 WC6, WC9, C5, C12, C12A, CA15; ASTM A351 CF8, CF8M, CF3, CF3M, CF8C, CN3MN, CK3MCUN, CN7M; ASTM A352 LCB, LCC; ASTM A494 CW-6MC, CU5MCuC, M35-1; ASTM A890 4A (CD3MN), 5A(CE3MN), 6A(CD3MWCuN); ASME B148 C95800, C95500

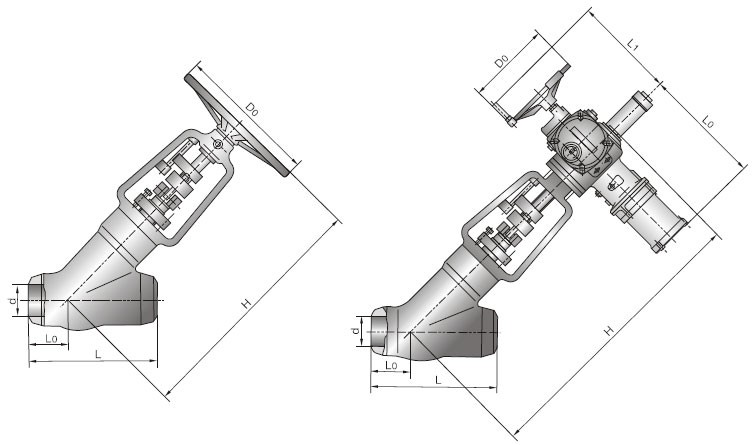

| Main dimensions Size NPS(in) |

Main dimensions and connection dimensions(mm) | ||||||||||||

| d | L | L0 | H | D0 | |||||||||

| J65Y-1500Lb | |||||||||||||

| 2 1/2 | 56 | 330 | 130 | 670 | 360 | ||||||||

| 3 | 64 | 368 | 140 | 750 | 460 | ||||||||

| 4 | 84 | 457 | 170 | 830 | 510 | ||||||||

| 5 | 100 | 533 | 185 | 910 | 560 | ||||||||

| 6 | 126 | 610 | 190 | 1100 | 610 | ||||||||

| J65Y-2500Lb | |||||||||||||

| 2 | 38 | 310 | 120 | 550 | 300 | ||||||||

| 2 1/2 | 46 | 340 | 130 | 670 | 360 | ||||||||

| 3 | 54 | 390 | 147 | 750 | 460 | ||||||||

| 4 | 70 | 480 | 170 | 830 | 720 | ||||||||

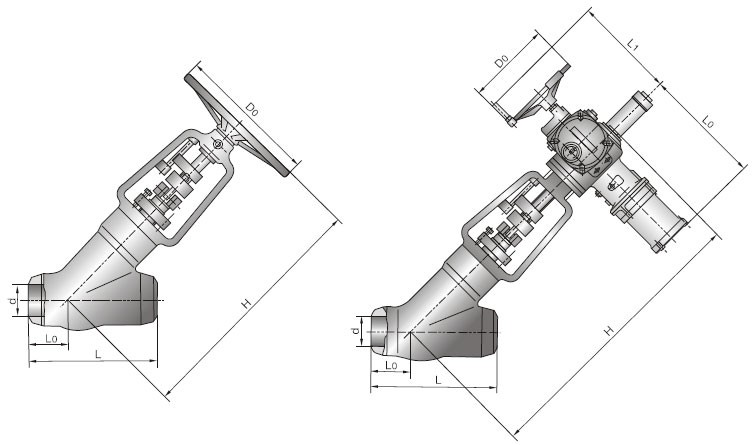

| Main dimensions Size NPS(in) |

Main dimensions and connection dimensions(mm) | Electric actuator | |||||||||||

| d | L | Lo | H | Do | L1 | L2 | |||||||

| J965Y-1500Lb | |||||||||||||

| 3 | 64 | 368 | 140 | 990 | 305 | 410 | 565 | SMC-0 | |||||

| 4 | 84 | 457 | 170 | 990 | 305 | 420 | 654 | SMC-1 | |||||

| 5 | 100 | 533 | 185 | 1115 | 305 | 420 | 654 | SMC-1 | |||||

| 6 | 126 | 610 | 190 | 1763 | 457 | 440 | 688 | SMC-2 | |||||

| 8 | 158 | 762 | 262 | 2026 | 457 | 440 | 688 | SMC-2 | |||||

| J965Y-2000Lb | |||||||||||||

| 4 | 80 | 457 | 170 | 990 | 305 | 420 | 654 | SMC-1 | |||||

| 5 | 96 | 533 | 185 | 1115 | 305 | 420 | 654 | SMC-1 | |||||

| 6 | 118 | 610 | 190 | 1423 | 457 | 440 | 688 | SMC-2 | |||||

| 8 | 148 | 762 | 262 | 1615 | 457 | 440 | 688 | SMC-2 | |||||

| 10 | 180 | 914 | 300 | 2240 | 610 | 715 | SMC-4 | ||||||

| 12 | 222 | 1041 | 360 | 2490 | 610 | 715 | SMC-4 | ||||||

| J965Y-2500Lb | |||||||||||||

| 2 | 38 | 310 | 120 | 810 | 305 | 400 | 555 | SMC-00 | |||||

| 2 1/2 | 46 | 340 | 130 | 895 | 305 | 400 | 555 | SMC-00 | |||||

| 3 | 54 | 390 | 140 | 985 | 305 | 410 | 565 | SMC-0 | |||||

| 4 | 70 | 480 | 170 | 990 | 305 | 420 | 654 | SMC-1 | |||||

| 5 | 86 | 580 | 185 | 1115 | 305 | 420 | 654 | SMC-1 | |||||

| 6 | 104 | 630 | 200 | 1280 | 457 | 440 | 688 | SMC-2 | |||||

| 8 | 130 | 770 | 260 | 1615 | 457 | 440 | 688 | SMC-2 | |||||

| 10 | 162 | 930 | 300 | 1930 | 610 | 690 | SMC-3 | ||||||

| 12 | 210 | 1060 | 360 | 2240 | 610 | 715 | SMC-4 | ||||||

| 14 | 234 | 1160 | 395 | 2420 | 610 | 715 | SMC-4 | ||||||

| J965Y-3500Lb | |||||||||||||

| 3 | 48 | 470 | 150 | 1005 | 305 | 410 | 565 | SMC-0 | |||||

| 4 | 60 | 550 | 115 | 1133 | 305 | 410 | 565 | SMC-0 | |||||

| 5 | 74 | 660 | 200 | 1280 | 305 | 420 | 654 | SMC-1 | |||||

| 6 | 88 | 790 | 230 | 1320 | 305 | 420 | 654 | SMC-1 | |||||

Comment Form