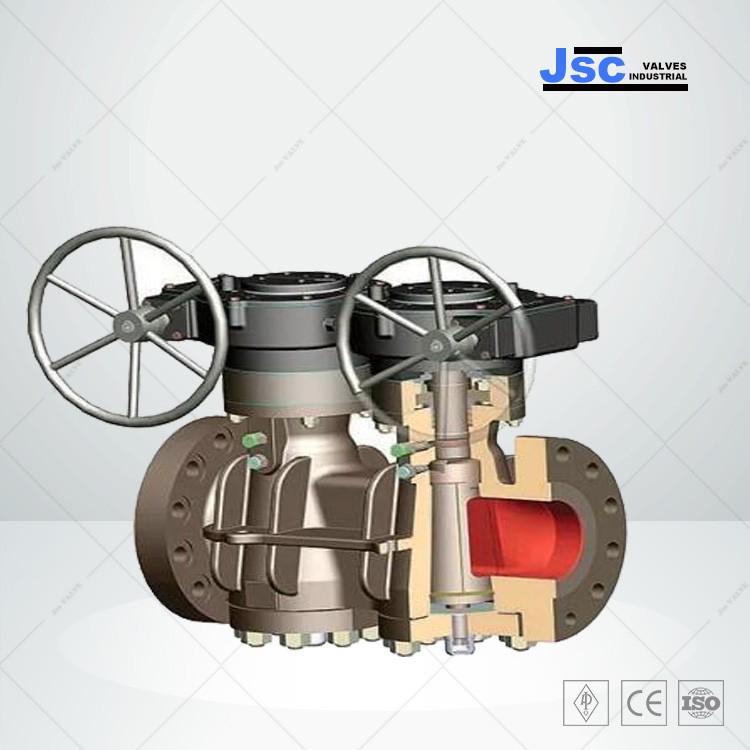

Pressure Balanced Twin Plug Valve, API 599, DIN 3202

Key Specifications / Features

Model No.: JSC-231206-PBPV-02

Hits: 39

Explore our Pressure Balanced Twin Plug Valve, manufactured in China. Sized from 1/2 to 24 inches, with class ratings ranging from 150 to 900 LB, this valve adheres to API 599 and DIN 3202 standards. Crafted from carbon and stainless steel, it features a double isolation design, ensuring optimal performance. Trust our factory's commitment to quality for your pressure-balanced twin plug valve needs.

Request a quote

Tags

Detail Information

Pressure Balanced Twin Plug Valve is designed for use in critical services where, verifiable tight shutoff is demanded. The design of the Double Isolation Lubricated Plug Valve is very compact with focus on space and weight savings. Furthermore, the design has far less possible leak paths compared to the conventional Double Block & Bleed Valve assemblies.

As a secondary seal, Pressure Balanced Twin Plug Valve is provided with a lubrication system which allows feeding a special lubricant into the valve while the valve is in operation. Besides, sealing, the purpose of the lubricant is to protect the internals of the valve against corrosion and wear as well as reducing the valve torque.

A new feature has been added to protect against possible overpressure in the inner cavities (between, in and below the two plugs), this feature is a Patented Pressure Relief Bore.

This feature is a bore going from the body sealing surface against the diaphragm, to the port outside of each plug. While operating normally, the bore is kept closed by the pressure of the bottom cover, obtained by studs and nuts, against the diaphragms.

A bleed port is available in configuration as per customer preference. This port allows access to verify the sealing of the valve itself. Any leakage past the first plug would be detected via the bleed port.

Pressure Balanced Twin Plug Valve Feature

1. Improved plant and personnel safety assured by a double isolation design that allows the operator to verify valve isolation before carrying out maintenance

2. A cost-, space- and weight-saving alternative to a double block and bleed system using two valves in a series

3. Ease of installation from a compact design with the same face-to-face dimension as a single valve, often replacing it without the need for pipe work modifications

4. Greater process control via pressure balanced design that provides a true bubble-tight double isolation capability within a single valve body

Design and manufacture: API 599, ASME B16.34, DIN 3202

Face to face dimensions: ASME B16.10

Flange ends: ASME B16.5

Butt-weld ends: ASME B16.25

Threaded ends: ASME B1.20.1

Socket-weld Ends: ASME B16.11

Valves Marking: MSS SP-25

Inspection and testing: API 598

Body material: ASTM A216 WCB, ASTM A352 LCB, Alloy Steel ASTM A217 WC6, WC9, Stainless Steel ASTM A351 CF8, CF8M, CF3, CF3M, Duplex ASTM A890 4A, 5A, Special Alloy, Monel, Bronze C95800, Alloy 20

Trim material: ASTM A216 WCB, ASTM A352 LCB, ASTM A105, Alloy Steel ASTM A217 WC6, WC9, ASTM A182 F11, Stainless Steel ASTM A351 CF8, CF8M, CF3, CF3M, ASTM A182 F304, F316, F304L, F316L, Duplex ASTM A890 4A, 5A, ASTM A182 F51, F55, Special Alloy, Monel, Bronze C95800, Alloy 20

Size range: 1/2 Inch - 24 Inch, DN15 - DN600

Pressure range: Class 150 LB - 900 LB

Drive Mode: Manual, Worm gear, Electric, Pneumatic

Field of Application: Electric/Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

As a secondary seal, Pressure Balanced Twin Plug Valve is provided with a lubrication system which allows feeding a special lubricant into the valve while the valve is in operation. Besides, sealing, the purpose of the lubricant is to protect the internals of the valve against corrosion and wear as well as reducing the valve torque.

A new feature has been added to protect against possible overpressure in the inner cavities (between, in and below the two plugs), this feature is a Patented Pressure Relief Bore.

This feature is a bore going from the body sealing surface against the diaphragm, to the port outside of each plug. While operating normally, the bore is kept closed by the pressure of the bottom cover, obtained by studs and nuts, against the diaphragms.

A bleed port is available in configuration as per customer preference. This port allows access to verify the sealing of the valve itself. Any leakage past the first plug would be detected via the bleed port.

Pressure Balanced Twin Plug Valve Feature

1. Improved plant and personnel safety assured by a double isolation design that allows the operator to verify valve isolation before carrying out maintenance

2. A cost-, space- and weight-saving alternative to a double block and bleed system using two valves in a series

3. Ease of installation from a compact design with the same face-to-face dimension as a single valve, often replacing it without the need for pipe work modifications

4. Greater process control via pressure balanced design that provides a true bubble-tight double isolation capability within a single valve body

Design and manufacture: API 599, ASME B16.34, DIN 3202

Face to face dimensions: ASME B16.10

Flange ends: ASME B16.5

Butt-weld ends: ASME B16.25

Threaded ends: ASME B1.20.1

Socket-weld Ends: ASME B16.11

Valves Marking: MSS SP-25

Inspection and testing: API 598

Body material: ASTM A216 WCB, ASTM A352 LCB, Alloy Steel ASTM A217 WC6, WC9, Stainless Steel ASTM A351 CF8, CF8M, CF3, CF3M, Duplex ASTM A890 4A, 5A, Special Alloy, Monel, Bronze C95800, Alloy 20

Trim material: ASTM A216 WCB, ASTM A352 LCB, ASTM A105, Alloy Steel ASTM A217 WC6, WC9, ASTM A182 F11, Stainless Steel ASTM A351 CF8, CF8M, CF3, CF3M, ASTM A182 F304, F316, F304L, F316L, Duplex ASTM A890 4A, 5A, ASTM A182 F51, F55, Special Alloy, Monel, Bronze C95800, Alloy 20

Size range: 1/2 Inch - 24 Inch, DN15 - DN600

Pressure range: Class 150 LB - 900 LB

Drive Mode: Manual, Worm gear, Electric, Pneumatic

Field of Application: Electric/Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

Comment Form