The Orbit Plug Valve: Mechanism, Features and Applications

An Orbit Plug Valve, also known as an eccentric plug valve, is a type of industrial valve commonly used in various applications to control the flow of fluids. The cutting-edge orbit plug valves, synonymous with innovation, are rapidly becoming a staple in sectors such as petroleum, chemicals, pharmaceuticals, fertilizers, and power, redefining how we approach pipeline connectivity.

1.Key Features of the Orbit Plug Valve

2. Applications and Operational Principle

Tailored for pipelines in industries requiring nominal pressures between CLASS 150 and 900LBS, the Orbit Plug Valve excels in seamlessly interrupting or connecting pipeline mediums. Its operational principle involves aligning the plug's channel with the valve body's channel when fully open, ensuring an optimal minimum pressure drop.

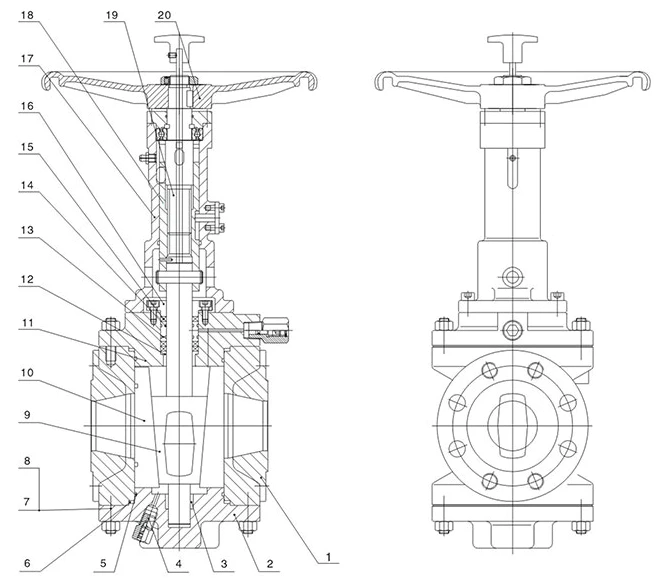

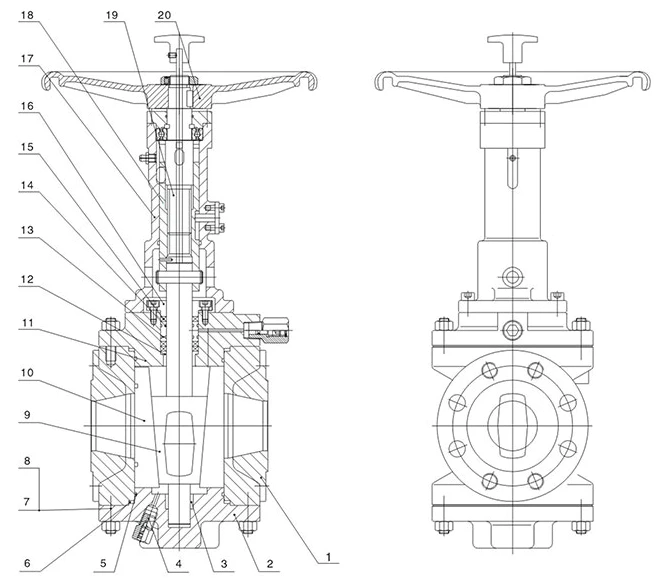

Rotating the handwheel initiates the plug's movement towards the valve, concurrently driving the valve disk by 90 degrees. Continuous handwheel rotation causes the plug to press down, opening the valve and tightly compressing the valve disk onto the seat for secure closure.

3. Advantages and Industry Transformations

The standout feature of the Orbit Plug Valve lies in its frictionless opening process, safeguarding the sealing surfaces from wear. With a soft seal ensuring zero leakage during closure, this valve signifies a paradigm shift in valve technology.

Equipped with an optional automatic pressure release device, the Orbit Plug Valve contributes significantly to operational safety, preventing abnormal pressure buildup within the valve chamber.

As industries embrace innovation, the Orbit Plug Valve takes center stage, propelling fluid control into a new era. Its inventive design, operational efficiency, and safety enhancements position it as an indispensable technology in fluid management applications. The Orbit Plug Valve is not just a valve; it's a trans-formative force shaping the future of pipeline operations.

1.Key Features of the Orbit Plug Valve

- Friction-Free Operation: Unlike traditional valves, the Orbit Plug Valve operates without any contact between the valve body sealing surface and the slide. This breakthrough design minimizes friction, reduces wear, and extends the valve's operational lifespan.

- Effortless Maintenance: Simplifying maintenance procedures, this valve allows for swift repairs without detaching it from the pipeline. A straightforward disassembly of the valve bottom cover and replacement of the slides ensure a hassle-free maintenance experience.

- Unrestricted Flow: With a full-bore structure, the valve body and plug offer an unimpeded flow area, eliminating the limitations associated with reduced-bore valves. This design facilitates optimal fluid flow through the pipeline.

- Robust Construction: The internal cavity of the Orbit Plug Valve is fortified with hard chrome plating, creating a durable and smooth sealing area that can withstand the rigors of industrial operations.

- Advanced Sealing: The elastic seal, featuring fluorine rubber molded into the slide's surface grooves, combined with a fire-resistant metal-to-metal seal, provides a dual-layered sealing mechanism for enhanced reliability.

2. Applications and Operational Principle

Tailored for pipelines in industries requiring nominal pressures between CLASS 150 and 900LBS, the Orbit Plug Valve excels in seamlessly interrupting or connecting pipeline mediums. Its operational principle involves aligning the plug's channel with the valve body's channel when fully open, ensuring an optimal minimum pressure drop.

Rotating the handwheel initiates the plug's movement towards the valve, concurrently driving the valve disk by 90 degrees. Continuous handwheel rotation causes the plug to press down, opening the valve and tightly compressing the valve disk onto the seat for secure closure.

3. Advantages and Industry Transformations

The standout feature of the Orbit Plug Valve lies in its frictionless opening process, safeguarding the sealing surfaces from wear. With a soft seal ensuring zero leakage during closure, this valve signifies a paradigm shift in valve technology.

Equipped with an optional automatic pressure release device, the Orbit Plug Valve contributes significantly to operational safety, preventing abnormal pressure buildup within the valve chamber.

As industries embrace innovation, the Orbit Plug Valve takes center stage, propelling fluid control into a new era. Its inventive design, operational efficiency, and safety enhancements position it as an indispensable technology in fluid management applications. The Orbit Plug Valve is not just a valve; it's a trans-formative force shaping the future of pipeline operations.