Pigging Valve Innovations: Streamlining Pipeline Maintenance and Cleaning

The Pigging Valve, a recent innovation in petroleum, natural gas, and chemical transportation, stands out as a cutting-edge device for pipeline cleaning. It is designed for launching and receiving pigging devices, allowing mechanical cleaning of pipeline interiors by removing impurities, rust, and foreign objects. The pivotal role of pigging valves extends across industries such as oil and gas fields, chemical plants, ports, storage facilities, and offshore platforms.

Major Pigging Valve Types

Pigging valves play a crucial role in pipeline maintenance and cleaning processes. There are several major types of pigging valves, each designed to serve specific functions in the pigging process. Here are some of the key types:

1. Launcher and Receiver Valves

2. Isolation Valves

Isolation valves are strategically placed along the pipeline to create isolated sections for pigging operations. These valves allow for controlled and safe pig movement between different segments of the pipeline.

3. Bypass Valves

Bypass valves provide an alternative route for the pig to pass through without entering the main pipeline. They are useful for diverting the pig during routine maintenance or in case of an issue in the main pipeline.

The Sealing Principle of Pigging Valve

The Pigging Valve employs a sealing principle akin to a ball valve. A spring and the medium collaboratively press the valve seats on both sides against the ball, creating a seal that separates the passage from the valve body cavity. To execute pigging operations, such as loading, launching, receiving, and retrieval, the ball is rotated. Loading or retrieving the pigging device is achieved when the ball channel aligns with the quick-opening blind plate. After a 90-degree rotation aligns the ball channel with the pipeline, the pigging device can be launched or received, facilitated by the medium's influence.

Key Applications of the Pigging Valve

Pipeline transportation stands out as the most efficient, cost-effective, and environmentally friendly method for transporting petroleum and natural gas, minimizing losses. The integration of pigging operations, driven by the innovative Pigging Valve and compatible devices, is pivotal in ensuring the seamless functioning of pipelines across diverse projects in the oil and gas industry.

Major Pigging Valve Types

Pigging valves play a crucial role in pipeline maintenance and cleaning processes. There are several major types of pigging valves, each designed to serve specific functions in the pigging process. Here are some of the key types:

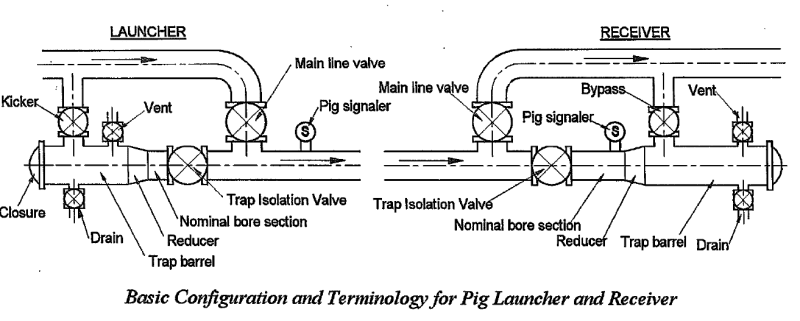

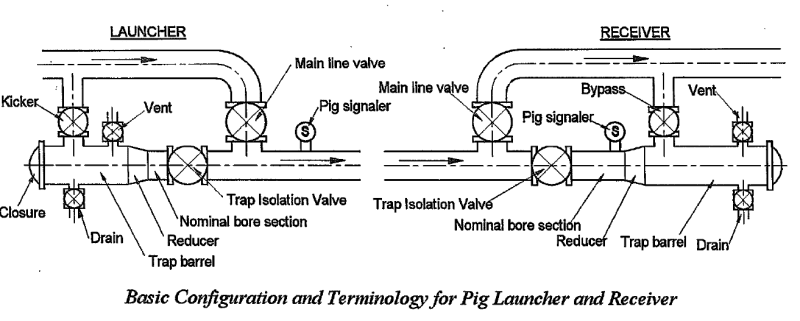

1. Launcher and Receiver Valves

- Launcher Valve: Positioned at the beginning of a pipeline, the launcher valve is responsible for safely introducing the pig into the pipeline.

- Receiver Valve: Placed at the end of the pipeline, the receiver valve captures the pig as it completes its journey, allowing for its safe removal from the pipeline.

2. Isolation Valves

Isolation valves are strategically placed along the pipeline to create isolated sections for pigging operations. These valves allow for controlled and safe pig movement between different segments of the pipeline.

3. Bypass Valves

Bypass valves provide an alternative route for the pig to pass through without entering the main pipeline. They are useful for diverting the pig during routine maintenance or in case of an issue in the main pipeline.

The Sealing Principle of Pigging Valve

The Pigging Valve employs a sealing principle akin to a ball valve. A spring and the medium collaboratively press the valve seats on both sides against the ball, creating a seal that separates the passage from the valve body cavity. To execute pigging operations, such as loading, launching, receiving, and retrieval, the ball is rotated. Loading or retrieving the pigging device is achieved when the ball channel aligns with the quick-opening blind plate. After a 90-degree rotation aligns the ball channel with the pipeline, the pigging device can be launched or received, facilitated by the medium's influence.

Key Applications of the Pigging Valve

- Pre-commissioning: Clears residues to ensure unobstructed pipelines before new pipeline operation.

- Rust removal and corrosion protection: Cleans rust and applies anti-corrosion coatings to the inner walls of new pipelines.

- Periodic wax removal and water removal: Regular pigging of operational pipelines ensures long-term effective transport capacity, minimizes internal corrosion, and extends pipeline lifespan.

- Isolation and product change in the same pipeline: Facilitates the transport of different types of media within the same pipeline while ensuring isolation.

- Pre-pressurization and drainage after hydrostatic testing: Assists in pre-pressurization before water testing and drainage post-testing.

Pipeline transportation stands out as the most efficient, cost-effective, and environmentally friendly method for transporting petroleum and natural gas, minimizing losses. The integration of pigging operations, driven by the innovative Pigging Valve and compatible devices, is pivotal in ensuring the seamless functioning of pipelines across diverse projects in the oil and gas industry.