Mud Gate Valve Advancements in Oil and Gas Fields

In the critical applications of wellhead equipment and Christmas trees in oil and gas fields, high-pressure single-disc flat gate valves have long been the primary choice for mud exclusion. However, these valves suffer from drawbacks such as a tall overall profile, significant space requirements for installation, extended opening and closing times, and high production costs. To overcome these challenges, we have innovated and developed the Mud Gate Valve based on the API Spec 6A standard. In comparison to its high-pressure single-disc flat gate valve counterparts, the Mud Gate Valve demonstrates approximately one-third reduction in overall height, nearly halved opening and closing times, and significantly lowered production costs.

1. Outstanding Performance of the Mud Gate Valve

The Mud Gate Valve operates within a broad pressure range, reaching from 3000 to 15000 psi, with nominal sizes ranging from 2-1/16 to 9 inches (DN53 - DN225). It can withstand the substantial alternating pressure shocks generated in oil and gas fields and is resilient against various environmental factors, including seismic activities. Praised for its exceptional performance and prolonged lifespan, the Mud Gate Valve has gained widespread acclaim and has proven effective in media shut-off or flow control within the usage system.

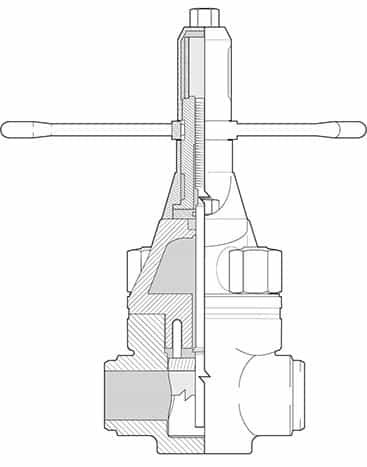

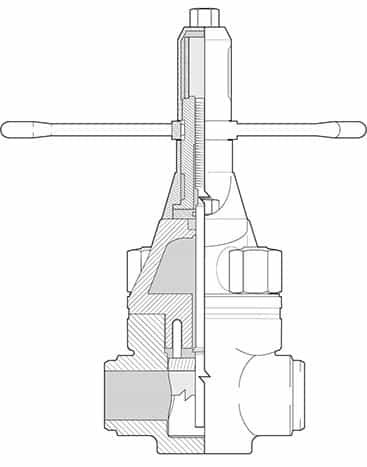

2. Innovative Sealing Structure Design

The Mud Gate Valve introduces an innovative sealing structure with a cylindrical seat design, consisting of two steel frameworks and a metal base support ring, all molded with sulfur-cured rubber on the surface. This design allows for the selection of appropriate rubber varieties based on the corrosiveness of the medium. The sealing form between the seat and the gate employs a structure that initiates with soft sealing followed by hard sealing, ensuring outstanding sealing performance even in media containing solid particles, such as mud. This sealing structure not only extends the valve's lifespan but also significantly reduces user operating costs while meeting the strict sealing requirements of the API Spec 6A standard.

3. Efficient Operation and Maintenance

The Mud Gate Valve incorporates a dual-thread structure for the valve stem nut, facilitating a swifter opening and closing process. Lubrication devices are installed on the handle, bracket, and valve cover, allowing lubricating oil to be injected through these devices to reduce friction between the valve stem nut, stem, and bracket. This design makes the Mud Gate Valve highly suitable for complex conditions in oil and gas wellhead equipment and Christmas trees, garnering popularity for its compact installation space, exceptional sealing performance, rapid opening and closing times, and minimal operating torque.

In essence, the Mud Gate Valve stands as a testament to innovation in valve technology, offering a reliable, efficient, and cost-effective solution for the intricate demands of oil and gas field operations. Its positive reception among users underscores its significance in enhancing overall system performance, contributing to the evolution of wellhead equipment and Christmas tree technologies.

1. Outstanding Performance of the Mud Gate Valve

The Mud Gate Valve operates within a broad pressure range, reaching from 3000 to 15000 psi, with nominal sizes ranging from 2-1/16 to 9 inches (DN53 - DN225). It can withstand the substantial alternating pressure shocks generated in oil and gas fields and is resilient against various environmental factors, including seismic activities. Praised for its exceptional performance and prolonged lifespan, the Mud Gate Valve has gained widespread acclaim and has proven effective in media shut-off or flow control within the usage system.

2. Innovative Sealing Structure Design

The Mud Gate Valve introduces an innovative sealing structure with a cylindrical seat design, consisting of two steel frameworks and a metal base support ring, all molded with sulfur-cured rubber on the surface. This design allows for the selection of appropriate rubber varieties based on the corrosiveness of the medium. The sealing form between the seat and the gate employs a structure that initiates with soft sealing followed by hard sealing, ensuring outstanding sealing performance even in media containing solid particles, such as mud. This sealing structure not only extends the valve's lifespan but also significantly reduces user operating costs while meeting the strict sealing requirements of the API Spec 6A standard.

3. Efficient Operation and Maintenance

The Mud Gate Valve incorporates a dual-thread structure for the valve stem nut, facilitating a swifter opening and closing process. Lubrication devices are installed on the handle, bracket, and valve cover, allowing lubricating oil to be injected through these devices to reduce friction between the valve stem nut, stem, and bracket. This design makes the Mud Gate Valve highly suitable for complex conditions in oil and gas wellhead equipment and Christmas trees, garnering popularity for its compact installation space, exceptional sealing performance, rapid opening and closing times, and minimal operating torque.

In essence, the Mud Gate Valve stands as a testament to innovation in valve technology, offering a reliable, efficient, and cost-effective solution for the intricate demands of oil and gas field operations. Its positive reception among users underscores its significance in enhancing overall system performance, contributing to the evolution of wellhead equipment and Christmas tree technologies.