Pneumatic Wafer Butterfly Valves: Efficiency and Versatility

The pneumatic wafer butterfly valve stands as a cornerstone in industrial pipeline systems, meticulously designed to optimize performance and ensure efficient fluid control. In this article, we will delve into the butterfly valve's structural features, major advantages, and diverse industrial applications, shedding light on its pivotal role in enhancing operational efficiency and reliability.

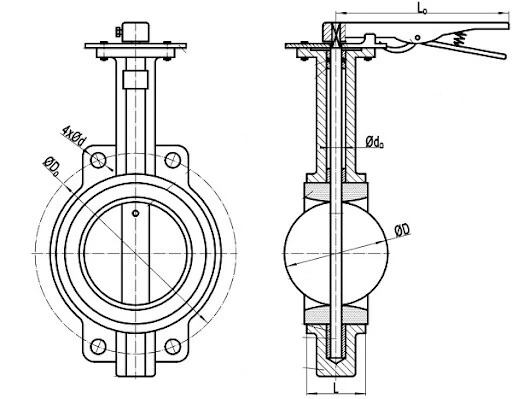

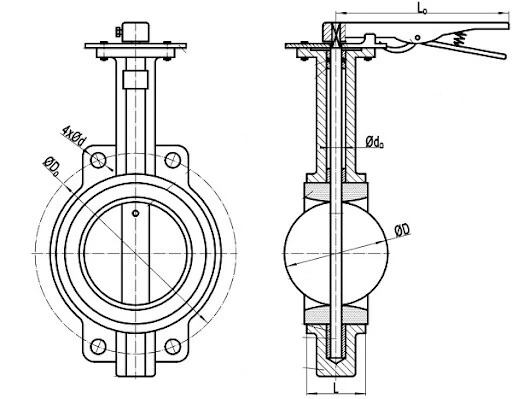

1. Structural Features

The structural design of the pneumatic wafer butterfly valve is meticulously crafted to optimize its performance within industrial pipeline systems. This section will delve into the key components and characteristics that define its structural integrity and operational efficiency.

2. Major Advantages

The pneumatic wafer butterfly valve offers a multitude of advantages that make it a preferred choice for fluid control applications in industrial settings. This section explores the key benefits that distinguish this valve from other types of control valves, highlighting its operational efficiency, reliability, and versatility.

3. Industrial Applications

The valve finds extensive utility in ventilation and environmental protection initiatives across industries, including chemicals, construction materials, power generation, and glass manufacturing, particularly in gas pipeline systems.

It serves as a reliable flow regulation or shut-off device for gas media, with a temperature range of ≤300°C and nominal pressures of 0.1 MPa, across a myriad of industrial processes.

The pneumatic wafer butterfly valve is a technologically advanced solution known for its superior structural design, operational efficiency, and versatility in various industrial applications. Its seamless integration into pipeline systems optimizes industrial processes, resulting in significant economic and societal benefits. With ongoing technological advancements, the valve is expected to enhance operational efficacy across diverse industrial domains.

1. Structural Features

The structural design of the pneumatic wafer butterfly valve is meticulously crafted to optimize its performance within industrial pipeline systems. This section will delve into the key components and characteristics that define its structural integrity and operational efficiency.

- The valve comprises a pneumatic piston-type actuator paired with a triple eccentric metal hard-sealed butterfly valve body.

- Distinguished by a piston-type design, the actuator ensures heightened torque, flexible rotation, and a streamlined construction.

- The butterfly disc, strategically positioned along the pipeline diameter, enables smooth rotation within the valve body, reaching a fully open position at a 90° angle.

- Versatility is inherent in the valve body, which accommodates various sealing configurations, including triple eccentric metal sealing, tetrafluoroethylene sealing, and double eccentric soft sealing, tailored to meet diverse operational demands.

2. Major Advantages

The pneumatic wafer butterfly valve offers a multitude of advantages that make it a preferred choice for fluid control applications in industrial settings. This section explores the key benefits that distinguish this valve from other types of control valves, highlighting its operational efficiency, reliability, and versatility.

- The valve's simplicity in structure, compact size, and lightweight design not only facilitates seamless installation and operation but also results in significant savings in labor and time.

- Its rapid opening and closing actions ensure a swift response, making it ideal for applications requiring prompt operation and thereby enhancing overall production efficiency.

- Minimal pressure drop during full opening underscores its exceptional flow control characteristics, addressing stringent process requirements with precision.

- The availability of elastic and metal sealing options enhances adaptability, allowing compatibility with a wide range of media and operating conditions.

- Longevity and automatic sealing functionality not only extend the valve's service life but also contribute to reduced maintenance expenses and mitigated leakage risks, enhancing overall system reliability and stability.

3. Industrial Applications

The valve finds extensive utility in ventilation and environmental protection initiatives across industries, including chemicals, construction materials, power generation, and glass manufacturing, particularly in gas pipeline systems.

It serves as a reliable flow regulation or shut-off device for gas media, with a temperature range of ≤300°C and nominal pressures of 0.1 MPa, across a myriad of industrial processes.

The pneumatic wafer butterfly valve is a technologically advanced solution known for its superior structural design, operational efficiency, and versatility in various industrial applications. Its seamless integration into pipeline systems optimizes industrial processes, resulting in significant economic and societal benefits. With ongoing technological advancements, the valve is expected to enhance operational efficacy across diverse industrial domains.