Electric Flat Gate Valves: Precision Manufacturing and Diverse Applications

The electric flat gate valve is a crucial gate valve in industrial pipelines, with its unique design and advanced manufacturing playing a significant role in fluid control. As representatives of electric flat gate valve manufacturers, we explore its intricate manufacturing process and showcase its outstanding performance of this gate valve in various applications.

1. Precision in Production

The intricate process of manufacturing electric motorized flat gate valves involves meticulous stages, ensuring the creation of a durable and reliable component for industrial pipeline systems.

2. Applications Across Industries

The versatility of electric motorized flat gate valves extends across various industrial domains, positioning them as indispensable components in pipeline systems due to their exceptional performance.

3. Pioneering Technology and Future Horizons

As dedicated manufacturers of electric motorized flat gate valves, our commitment to technological innovation stands at the forefront to meet evolving market demands.

In summary, the multifaceted aspects of electric motorized flat gate valves, from precision manufacturing to versatile applications and future-oriented innovations, position them as integral components driving the continual progression of the industrial sector.

1. Precision in Production

The intricate process of manufacturing electric motorized flat gate valves involves meticulous stages, ensuring the creation of a durable and reliable component for industrial pipeline systems.

1.1 Material Selection

The selection of premium-quality materials, specifically special alloy materials with corrosion resistance, high-temperature endurance, and pressure resilience, is foundational to the durability of the valve in harsh operating conditions.

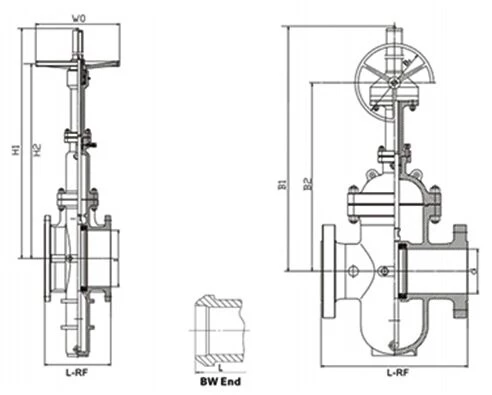

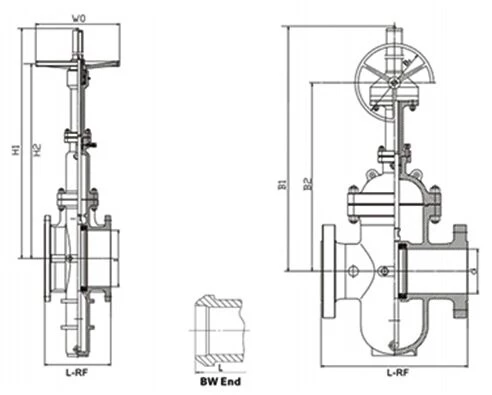

1.2 Design Excellence

The design phase explores fluid dynamics, mechanical structures, and electrical controls comprehensively. This approach guarantees stable and reliable operation across diverse conditions, incorporating state-of-the-art CNC machining and automated production lines for enhanced uniformity and precision.

1.3 Quality Assurance

Rigorous quality testing, spanning sealing performance, pressure resistance, and electrical functionality, ensures that every electric motorized flat gate valve adheres to exacting quality standards, solidifying the reputation of these products in the competitive market.

The selection of premium-quality materials, specifically special alloy materials with corrosion resistance, high-temperature endurance, and pressure resilience, is foundational to the durability of the valve in harsh operating conditions.

1.2 Design Excellence

The design phase explores fluid dynamics, mechanical structures, and electrical controls comprehensively. This approach guarantees stable and reliable operation across diverse conditions, incorporating state-of-the-art CNC machining and automated production lines for enhanced uniformity and precision.

1.3 Quality Assurance

Rigorous quality testing, spanning sealing performance, pressure resistance, and electrical functionality, ensures that every electric motorized flat gate valve adheres to exacting quality standards, solidifying the reputation of these products in the competitive market.

2. Applications Across Industries

The versatility of electric motorized flat gate valves extends across various industrial domains, positioning them as indispensable components in pipeline systems due to their exceptional performance.

- Chemical Industry: In the chemical industry, these valves play a critical role in regulating the flow of corrosive media, assuring secure and stable production processes.

- Energy Sector: In the energy sector, their widespread use in oil and gas pipeline systems enables precise fluid control.

- Water Treatment: In water treatment, intelligent control systems manage and optimize water supply systems, enhancing overall water resource utilization efficiency.

3. Pioneering Technology and Future Horizons

As dedicated manufacturers of electric motorized flat gate valves, our commitment to technological innovation stands at the forefront to meet evolving market demands.

3.1 Research and Development

We are poised to intensify our research and development endeavors, particularly in intelligent control technology, aiming to propel the widespread application of electric motorized flat gate valves within the realm of industrial automation.

3.2 Environmental Stewardship

Simultaneously, our attention is attuned to environmental stewardship and energy efficiency. Through meticulous design optimization and discerning material choices, our goal is to enhance the overall energy efficiency of electric motorized flat gate valves, offering customers sustainable and forward-thinking solutions.

We are poised to intensify our research and development endeavors, particularly in intelligent control technology, aiming to propel the widespread application of electric motorized flat gate valves within the realm of industrial automation.

3.2 Environmental Stewardship

Simultaneously, our attention is attuned to environmental stewardship and energy efficiency. Through meticulous design optimization and discerning material choices, our goal is to enhance the overall energy efficiency of electric motorized flat gate valves, offering customers sustainable and forward-thinking solutions.

In summary, the multifaceted aspects of electric motorized flat gate valves, from precision manufacturing to versatile applications and future-oriented innovations, position them as integral components driving the continual progression of the industrial sector.