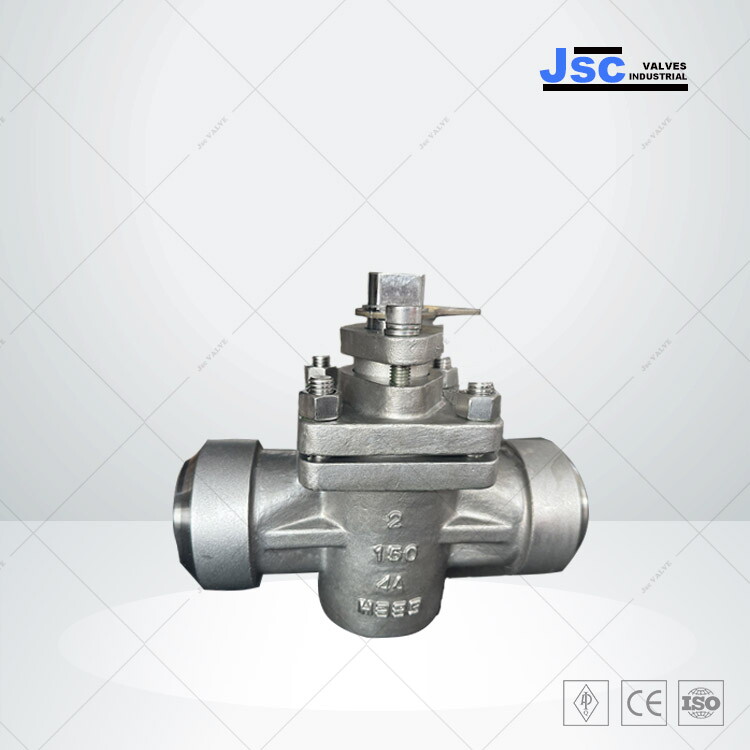

ASTM A890 4A Plug Valve, API 599, 2 IN, CL 150 LB, Soft Seal

Key Specifications / Features

Model No.: JSC-240327-SPV-01

Hits: 24

Our PTFE sleeved plug valve, compliant with ASTM A890 4A standards and designed according to API 599 specifications, comes in a 2-inch size with a Class 150 LB rating. It features a lever operation mechanism and RF end connections, ensuring reliable performance and easy operation in various industrial applications.

Request a quote

Tags

Detail Information

ASTM A890 4A PTFE Sleeved Plug Valve

Valve description: Sleeved plug valve, PTFE seat, regular bore

Body material: ASTM A890 4A

Nominal diameter: 2 Inch (DN50)

Nominal pressure: Class 150 LB (PN20)

Face to face: ASME B16.10

Test and inspection: API 598

Design & manufacture: API 599

Metal seat: PTFE

End connection: RF

Mode of operation: Lever

ASTM A890 4A (Duplex Steel F51, CD3MN, UNS S31803, Duplex 2205) Plug Valve exhibits excellent resistance to acid corrosion. It features a manual switch, flange-connected design, and PTFE soft seal, primarily utilized in industries such as chlor-alkali, soda ash, pharmaceuticals, fertilizers, fine chemicals, textile fiber synthesis, dyeing, production of basic organic acids and inorganic salts, as well as the nitric acid industry.

ASTM A890 4A PTFE Sleeved Plug Valve - Product Features

1. The structure of the ASTM A890 4A Plug Valve is reasonable, featuring reliable sealing, excellent performance, and an appealing shape.

2. Sealing in the ASTM A890 4A Plug Valve is accomplished by the sealing surface surrounding the card sleeve, with a unique 360° metal lip providing protection and fixing the sleeve.

3. The ASTM A890 4A Plug Valve is designed without any cavities to accumulate the medium.

4. The metal lip in the cock rotation provides a self-cleaning function, making it suitable for conditions with thick and easily scaling substances.

5. It allows for two-way flow, enhancing convenience during installation.

6. Parts material and flange size can be selected reasonably based on actual working conditions or user requirements to meet various engineering needs.

ASTM A890 4A PTFE Sleeved Plug Valve - Specifications and Materials

Design & manufacture: API 599, ASME B16.34, DIN 3202

Pressure rating: Class 150 LB - 600 LB, 1.0 MPa - 11.0 MPa, JIS 10K - 40K

Size range: NPS 1/2 Inch – 24 Inch, DN15 - DN600

Bore: Full bore, Reduced bore

Sleeve Material: PTFE, RPTFE, TFM, GF2P, PPL, PFA

Face to face dimensions: ASME B16.10

Flange ends: ASME B16.5

Butt-weld ends: ASME B16.25

Threaded Ends: ASME B1.20.1

Socket-weld Ends: ASME B16.11

Valves Marking: MSS SP-25

Inspection and testing: API 598

Drive Mode: Manual, Worm gear, Electric, Pneumatic

Field of Application: Electric/Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

Valve description: Sleeved plug valve, PTFE seat, regular bore

Body material: ASTM A890 4A

Nominal diameter: 2 Inch (DN50)

Nominal pressure: Class 150 LB (PN20)

Face to face: ASME B16.10

Test and inspection: API 598

Design & manufacture: API 599

Metal seat: PTFE

End connection: RF

Mode of operation: Lever

ASTM A890 4A (Duplex Steel F51, CD3MN, UNS S31803, Duplex 2205) Plug Valve exhibits excellent resistance to acid corrosion. It features a manual switch, flange-connected design, and PTFE soft seal, primarily utilized in industries such as chlor-alkali, soda ash, pharmaceuticals, fertilizers, fine chemicals, textile fiber synthesis, dyeing, production of basic organic acids and inorganic salts, as well as the nitric acid industry.

ASTM A890 4A PTFE Sleeved Plug Valve - Product Features

1. The structure of the ASTM A890 4A Plug Valve is reasonable, featuring reliable sealing, excellent performance, and an appealing shape.

2. Sealing in the ASTM A890 4A Plug Valve is accomplished by the sealing surface surrounding the card sleeve, with a unique 360° metal lip providing protection and fixing the sleeve.

3. The ASTM A890 4A Plug Valve is designed without any cavities to accumulate the medium.

4. The metal lip in the cock rotation provides a self-cleaning function, making it suitable for conditions with thick and easily scaling substances.

5. It allows for two-way flow, enhancing convenience during installation.

6. Parts material and flange size can be selected reasonably based on actual working conditions or user requirements to meet various engineering needs.

ASTM A890 4A PTFE Sleeved Plug Valve - Specifications and Materials

Design & manufacture: API 599, ASME B16.34, DIN 3202

Pressure rating: Class 150 LB - 600 LB, 1.0 MPa - 11.0 MPa, JIS 10K - 40K

Size range: NPS 1/2 Inch – 24 Inch, DN15 - DN600

Bore: Full bore, Reduced bore

Sleeve Material: PTFE, RPTFE, TFM, GF2P, PPL, PFA

Face to face dimensions: ASME B16.10

Flange ends: ASME B16.5

Butt-weld ends: ASME B16.25

Threaded Ends: ASME B1.20.1

Socket-weld Ends: ASME B16.11

Valves Marking: MSS SP-25

Inspection and testing: API 598

Drive Mode: Manual, Worm gear, Electric, Pneumatic

Field of Application: Electric/Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

Comment Form