ASTM A105N Y-type Globe Valve, 1-1/2 Inch, 800 LB, NPT Ends

Key Specifications / Features

Model No.: JSC-240524-FSGLV-01

Hits: 45

Present our ASTM A105N Y-Type Globe Valve. This valve adheres to API 602 standards, ensuring quality performance. Sized at 1-1/2 inches (DN40) for Class 800 LB and PN150 applications, it's suitable for demanding environments. Featuring a bolted bonnet, reduced bore design, and NPT ends connection, it offers secure sealing and easy installation. Our valve provides dependable performance you can rely on in various industrial applications.

Request a quote

Tags

Detail Information

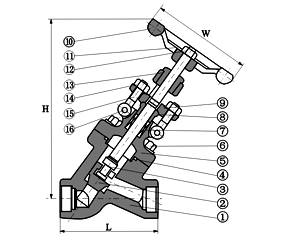

Y Pattern Forged Globe Valve

Valve description: Bolted bonnet, Reduced bore, socket, plug, Plug disc, parabolic disc, renewable seat.

Body material: ASTM A105N

Design Standard: API 602

Nominal diameter: 1-1/2 Inch (DN40)

Nominal class: Class 800 LB (PN150)

Metal seat: STL

End connection: NPT

Face to face: MFR, API 602

Test and inspection: API 598

Mode of operation: Handwheel

A forged steel Y-type globe valve is a valve where the closing part, or disc, moves along the centerline of the valve seat. The change in the valve seat opening is proportional to the movement of the disc. Due to its relatively short opening or closing stroke and highly reliable shut-off function, the Y-type forged steel globe valve is well-suited for flow regulation. The proportional relationship between the valve seat opening and the disc stroke makes it ideal for both shutting off and regulating or throttling the flow.

Y Pattern Forged Globe Valve: Design Structure and Features

1. Applicable Standard

Design Standard: API 602, ASME B16.34, BS 5352, DIN 3352

Face to Face: ASME B16.10, EN 558, DIN 3202

End Flange: ASME B16.5, DIN 2533

Butt Welding Ends: ASME B16.25, DIN3239

Socket Welded Ends: ASME B16.11

Threaded Ends: ASME B1.20.1

Inspection and Test: API 598, DIN 3202

2. Products Range

Size Range: 1/2 Inch - 3 Inch (DN15-DN80)

Pressure Range: ANSI Class 150 LB-4500 LB

Body Materials: ASTM A105, ASTM A350 LF2, ASTM A182 F9, F11, F22, ASTM A182 F304, F304L, F316, F316L, ASTM A182 F321, F51, Alloy Steel, etc.

| No | Name | CS to ASTM | AS to ASTM | SS to ASTM | |

| A105 | F22 | F304 (L) | F316 (L) | ||

| 1 | Body | A105 | A182 F22 | A182 F304 (L) | A182 F316 (L) |

| 2 | Disc | A27 6420 | A276 304 | A276 304 (L) | A276 316 (L) |

| 3 | Stem | A182F6 | A182 F304 | A182 F304 (L) | A182 F316 (L) |

| 4 | gasket | 316+graphite | 316+PTFE | ||

| 5 | bonnet | A105 | A276 304 | A182 F304 (L) | A182 F316 (L) |

| 6 | Bolt | A19 3B7 | A193 B16 | A193 B8 | A193 B8M |

| 7 | Packing | Graphite | PTFE | ||

| 8 | sleeve | A276 410 | A182 F304(L) | A182 F316 (L) | |

| 9 | Gland | A216 WCB | A351 CF8 | ||

| 10 | Handwheel | A197 | |||

| 11 | Nameplate | SS | |||

| 12 | nut | A194 2H | A194 4 | A194 8 | A194 8M |

| 13 | Stem nut | A276 410 | |||

| 14 | Bolt | A194 2H | A194 4 | A194 8 | A194 8M |

| 15 | Eyebolt | A193 B7 | A193 B16 | A193 B8 | A193 B8M |

Comment Form